Preparation method of magnesium ferrite nanofiber negative electrode material

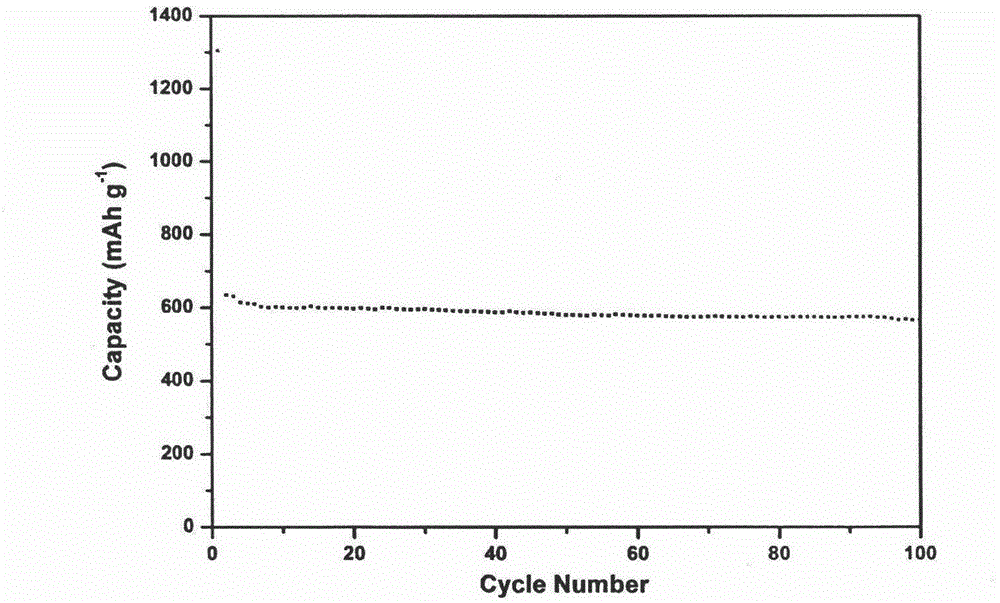

A nanofiber and anode material technology, applied in the fields of nanomaterials and chemical power sources, can solve the problems of poor cycle stability and no substantial application value, and achieve high discharge platform, stable cycle performance, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

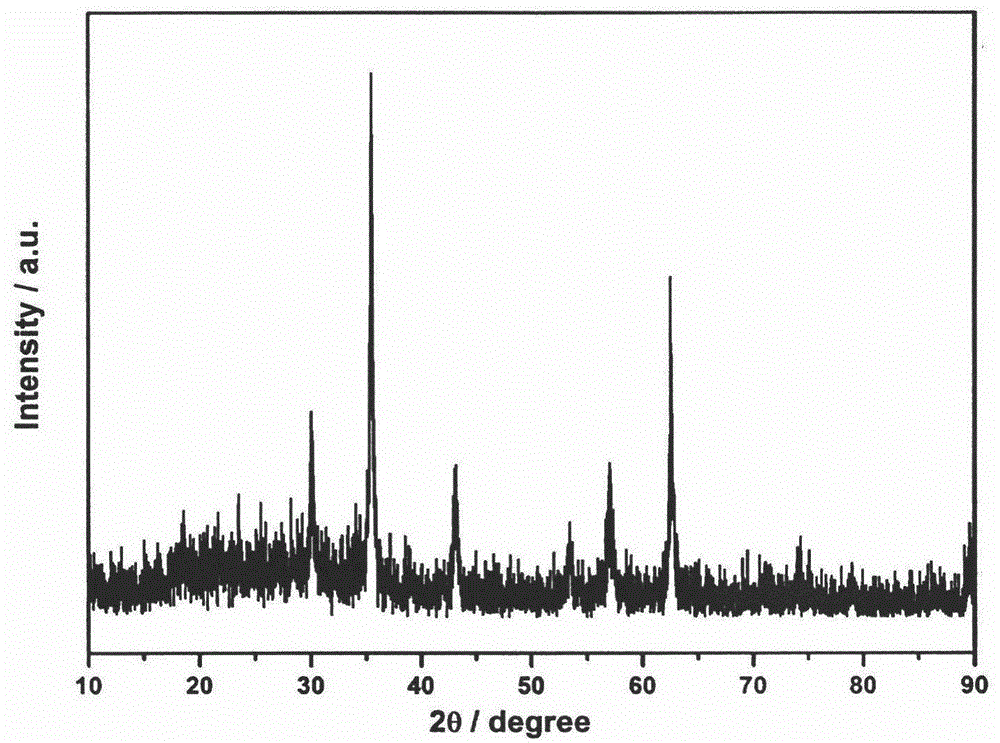

Image

Examples

Embodiment 1

[0018] Weigh 3.0g of PVP and dissolve it in 8.5g DMF and 8.5g ethanol mixed solvent, prepare a solution with a mass fraction of 15%, put it into a magnetic rotor, and stir at room temperature for 8 to 24 hours. After the solution is evenly stirred, add 0.1256 C of g 4 h 6 MgO 4 4H 2 O and 0.4744g of Fe(NO 3 ) 3 9H 2 O(C 4 h 6 MgO 4 4H 2 O and Fe(NO 3 ) 3 9H 2 The molar ratio of O is 1:2), and continue to stir at room temperature for 5-10 hours until a brown homogeneous solution is obtained. Then, the uniform spinning solution configured was spun in a self-made electrospinning device, the spinning voltage was 18kV, the receiving distance was 16cm, and the spinning speed was 0.5mL / h to obtain PVP / C 4 h 6 MgO 4 / Fe(NO 3 ) 3 Composite nanofiber membrane. Then put the obtained composite nanofibrous membrane into a tube furnace for calcination, raise the temperature from room temperature to 800°C in an air atmosphere, keep the temperature for 3h, the heating rate i...

Embodiment 2

[0020] Weigh 3.0g of PVP and dissolve in 8.5g DMF and 8.5g ethanol mixed solvent, prepare a solution with a mass fraction of 15%, put it into a magnetic rotor, and stir at room temperature for 8 to 24 hours. After the solution is evenly stirred, add 0.1884 C of g 4 h 6 MgO 4 4H 2 O and 0.7116g of Fe(NO 3 ) 3 9H 2 O(C 4 h 6 MgO 4 4H 2 O and Fe(NO 3 ) 3 9H 2 The molar ratio of O is 1:2), and continue to stir at room temperature for 5-10 hours until a brown homogeneous solution is obtained. Then, the uniform spinning solution configured was spun in a self-made electrospinning device, the spinning voltage was 20kV, the receiving distance was 18cm, and the spinning speed was 0.5mL / h to obtain PVP / C 4 h 6 MgO 4 / Fe(NO 3 ) 3 Composite nanofiber membrane. Then put the obtained composite nanofiber membrane into a tube furnace for calcination, raise the temperature from room temperature to 800°C in an air atmosphere, keep the temperature for 3h, and the heating rate is...

Embodiment 3

[0022] Weigh 2.4g of PVP and dissolve it in 8.8g DMF and 8.8g ethanol mixed solvent, prepare a solution with a mass fraction of 12%, put it into a magnetic rotor, and stir at room temperature for 8 to 24 hours. After the solution is evenly stirred, add 0.1884 C of g 4 h 6 MgO 4 4H 2 O and 0.7116g of Fe(NO 3 ) 3 9H 2 O(C 4 h 6 MgO 4 4H 2 O and Fe(NO 3 ) 3 9H 2 The molar ratio of O is 1:2), and continue to stir at room temperature for 5-10 hours until a brown homogeneous solution is obtained. Then, the uniform spinning solution configured was spun in a self-made electrospinning device, the spinning voltage was 18kV, the receiving distance was 20cm, and the spinning speed was 0.5mL / h to obtain PVP / C 4 h 6 MgO 4 / Fe(NO 3 ) 3Composite nanofiber membrane. Then put the obtained composite nanofibrous membrane into a tube furnace for calcination, raise the temperature from room temperature to 600°C in an air atmosphere, keep the temperature for 3h, the heating rate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com