Welding-free, lamination-free, dismantable and recyclable photovoltaic assembly

A photovoltaic module and welding-free technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as inability to effectively peel off, sort and recycle, explosion of heat-conducting oil in laminator, pollution, etc., so as to prevent safe production Hidden dangers, prevention of cell oxidation, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

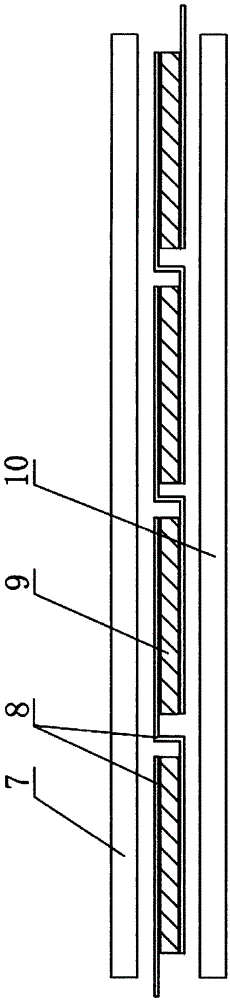

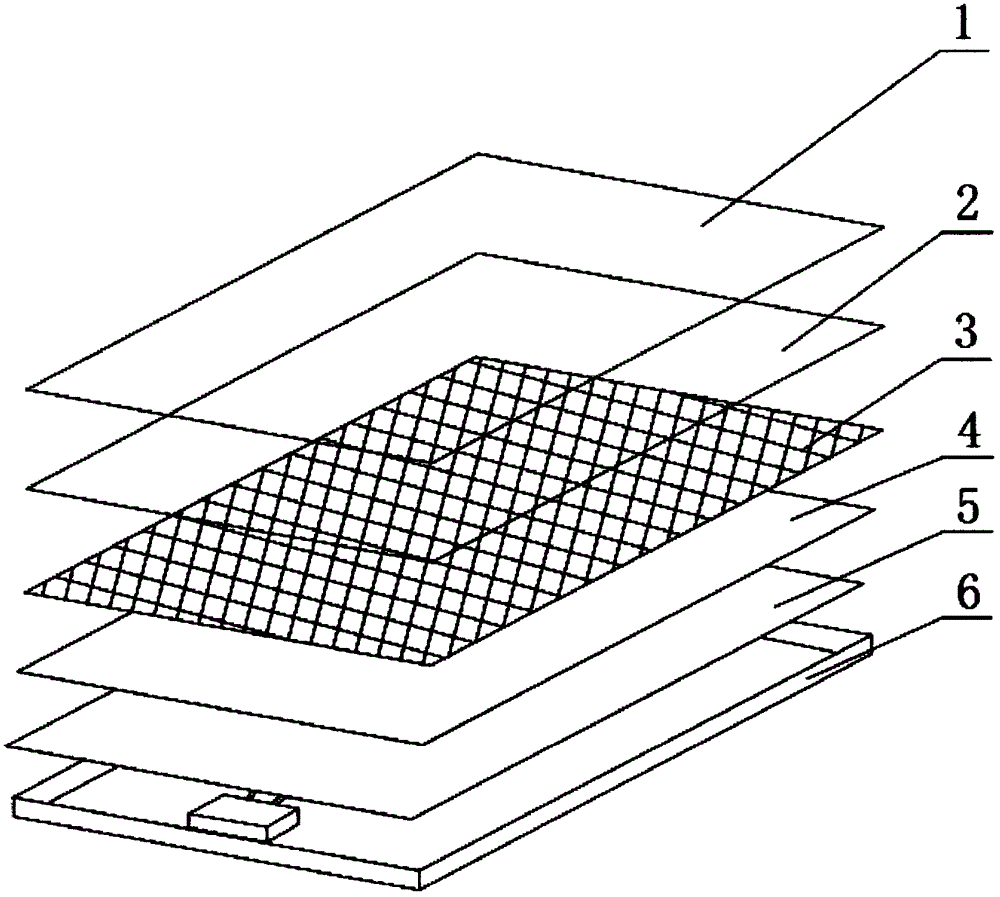

[0029] A welding-free, lamination-free, detachable and recyclable photovoltaic module, the photovoltaic module includes a front material 7, a cell string, and a back plate 10 arranged in sequence from top to bottom; the cell string is composed of several The double-sided conductive tape 8 is obtained by connecting several battery slices 9 in series. The photovoltaic module is composed of photovoltaic glass or PMMA transparent plexiglass, double-sided conductive tape, cell string, double-sided conductive tape, PMMA plexiglass or other anti-aging organic material. One side of the double-sided conductive tape 8 is adhered to the positive or negative pole of the battery sheet 9, and the other side of the double-sided conductive tape 8 is connected to the lower surface of the front material 7 or the upper surface of the back plate 10. Adhesion. The adhesion between the double-sided conductive tape 8 and the front material 7 , the battery sheet 9 and the back plate 10 is all detach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com