Novel dairy product filling device

A filling device, a technology for dairy products, applied in packaging, bottle filling, liquid bottling, etc., can solve problems such as large gaps, and achieve the effect of improving production speed and efficiency, safety and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

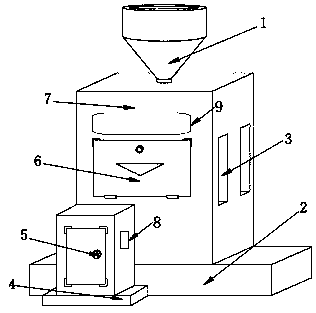

[0012] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] refer to figure 1 , a new type of dairy product filling device, including a mixture input hopper 1, a base 2, a sterilized uniform filling device 3, an electric box moisture-proof board 4, an electric control box 5, a maintenance door 6, and a filling machine shell 7. The lower end of the mixture input hopper 1 is embedded and installed to be welded with the upper end of the filling machine shell 7 and is perpendicular to each other. The lower end of the maintenance door 6 is connected to the front end of the filling machine shell 7 through a hinge. The left end of the sterilizing uniform filling device 3 is Embedded and installed in the casing 7 of the filling machine, the lower end of the casing 7 of the filling machine is welded to the upper end of the base 2 and is perpendicular to each other, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com