Coated steel sheet manufacturing apparatus using inkjet printing

A technology of manufacturing device and printing device, applied in the field of manufacturing device of coated steel plate, can solve the problems of slow operation speed, poor productivity, complicated production process, etc., and achieve the effects of high production speed and efficiency, prevention of damage, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Embodiments of the present invention will be described in detail below with reference to the drawings.

[0082] The embodiments described below are examples to enable those skilled in the art to which the present invention pertains to more fully understand the concept of the present invention. The present invention is not limited to the Examples described below, but can be embodied in other forms. In order to clearly illustrate the present invention, parts irrelevant to the description are omitted in the drawings, and the width, length, thickness, etc. of the constituent elements may be shown enlarged in the drawings for easy understanding. The same reference numerals denote the same constituent elements in the specification.

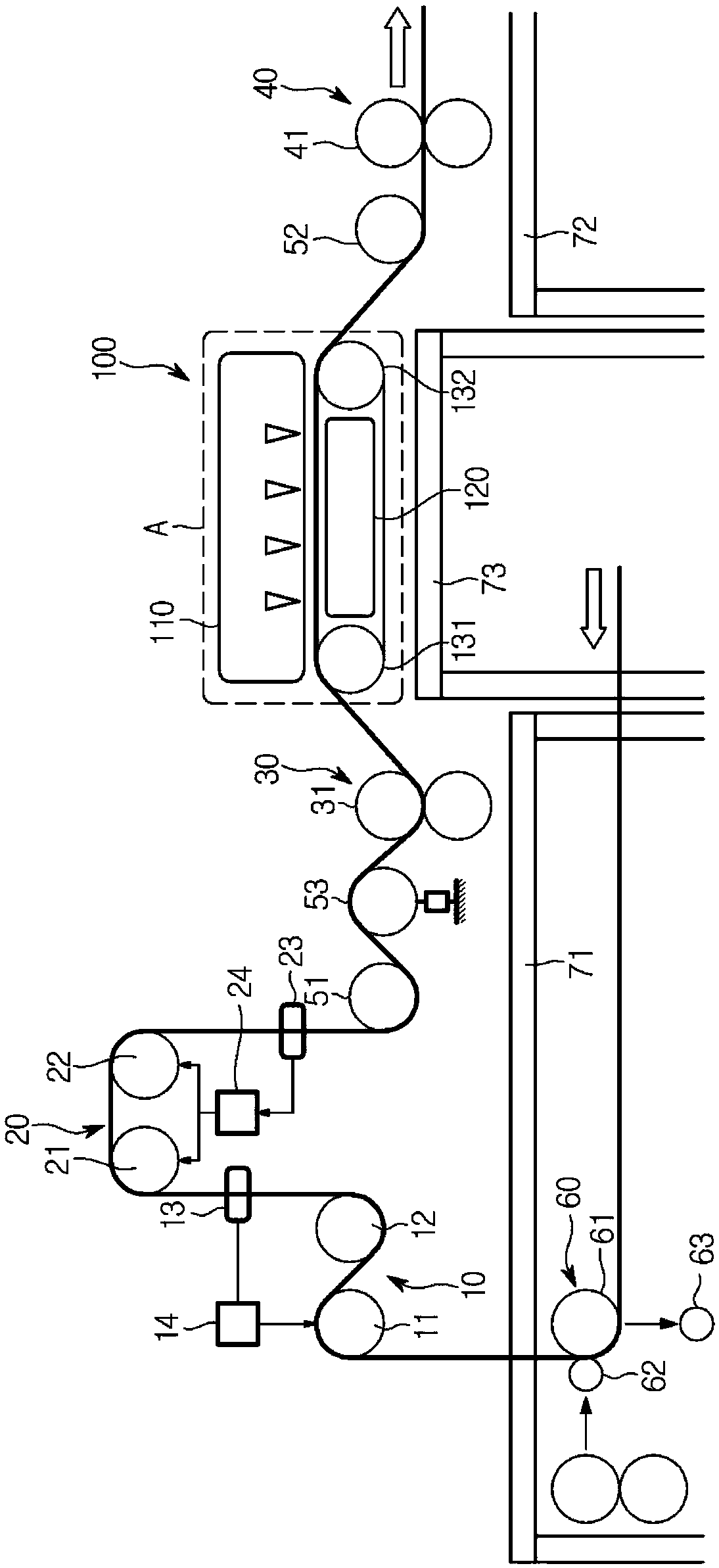

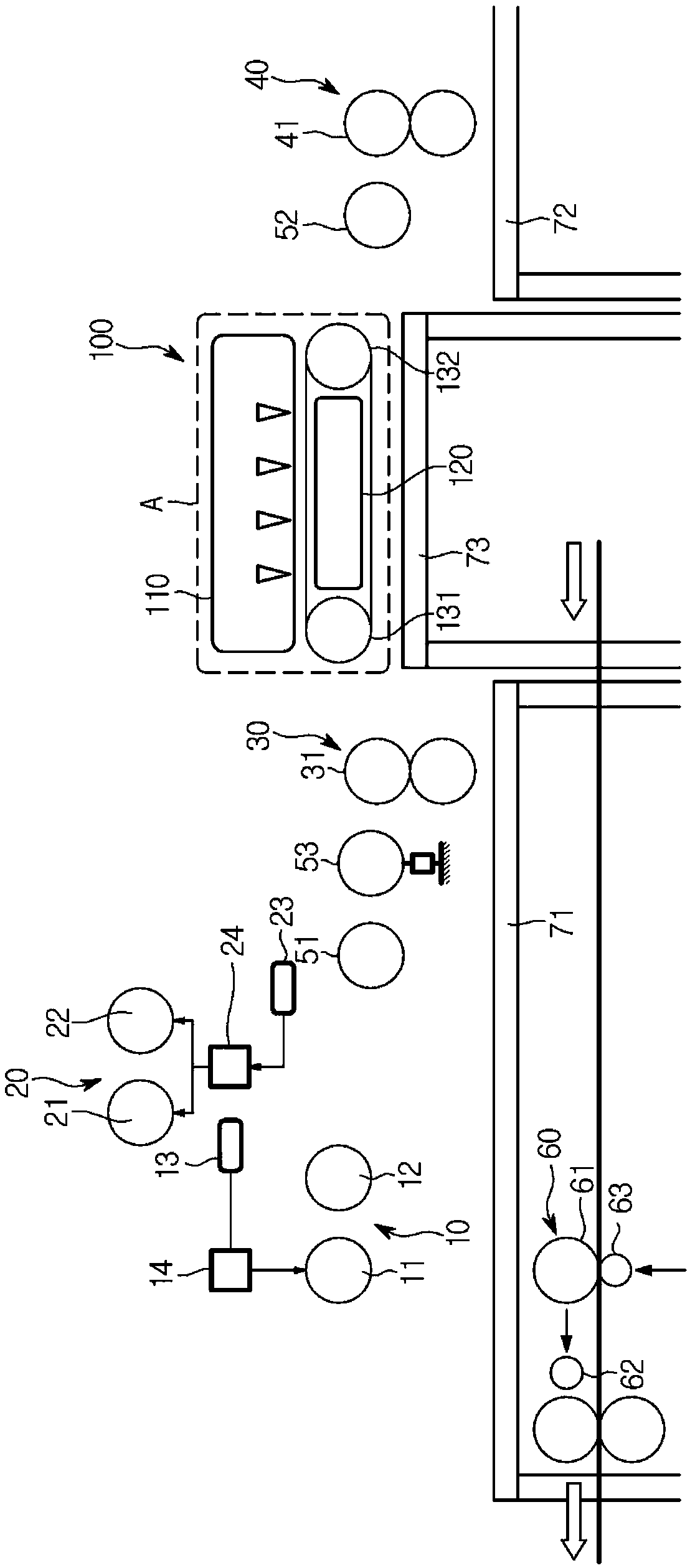

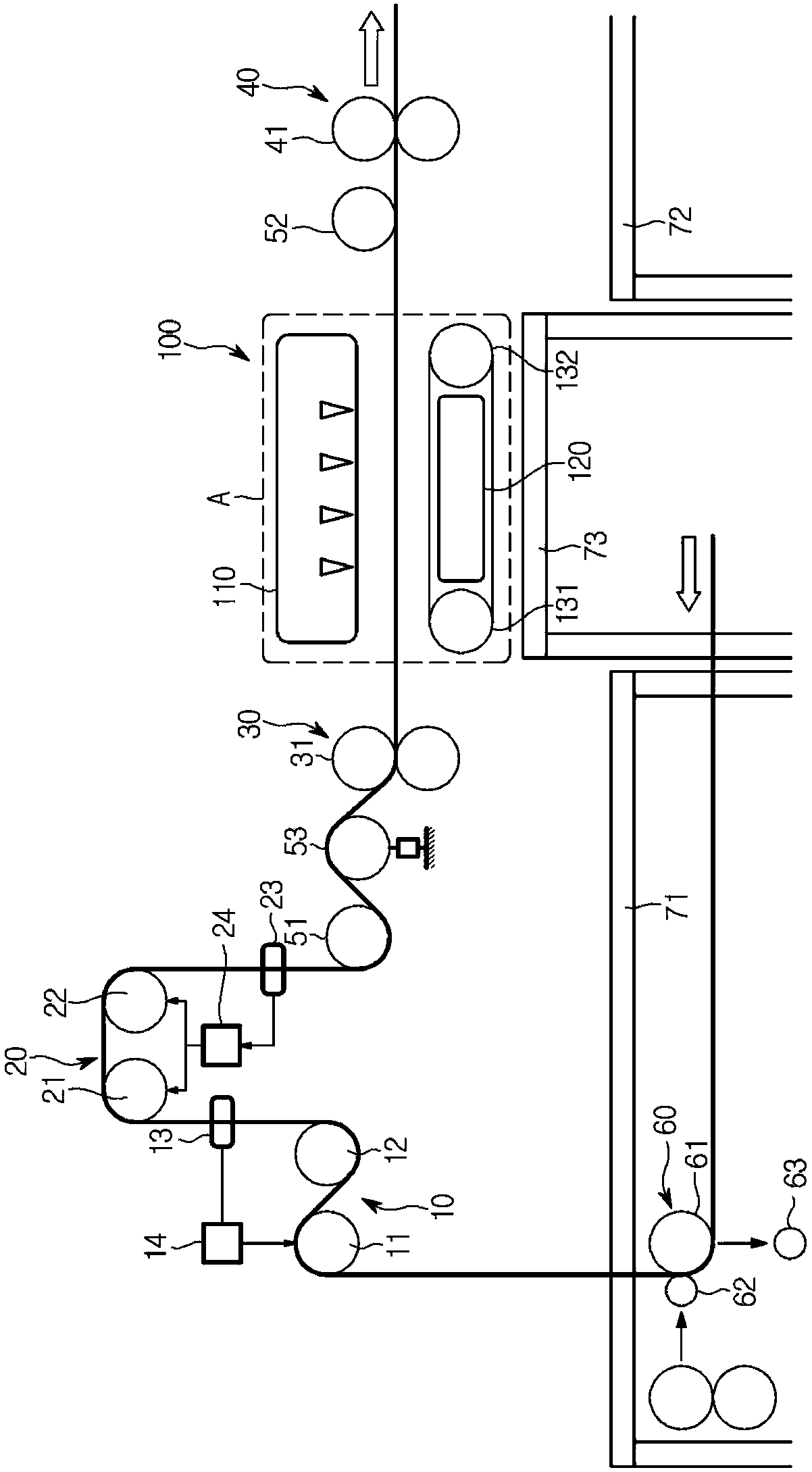

[0083] figure 1 It is a figure which schematically shows the manufacturing apparatus of the coated steel plate which concerns on the 1st Example of this invention.

[0084] Although not shown in the figure, the steel plate may undergo a proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com