Preparation method of ultrathin and ultra-flexible graphene conductive film

A conductive film and graphene technology, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., can solve the problems of unevenness of ultra-thin substrate, affecting the complete transfer of graphene, and inability to be completely flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

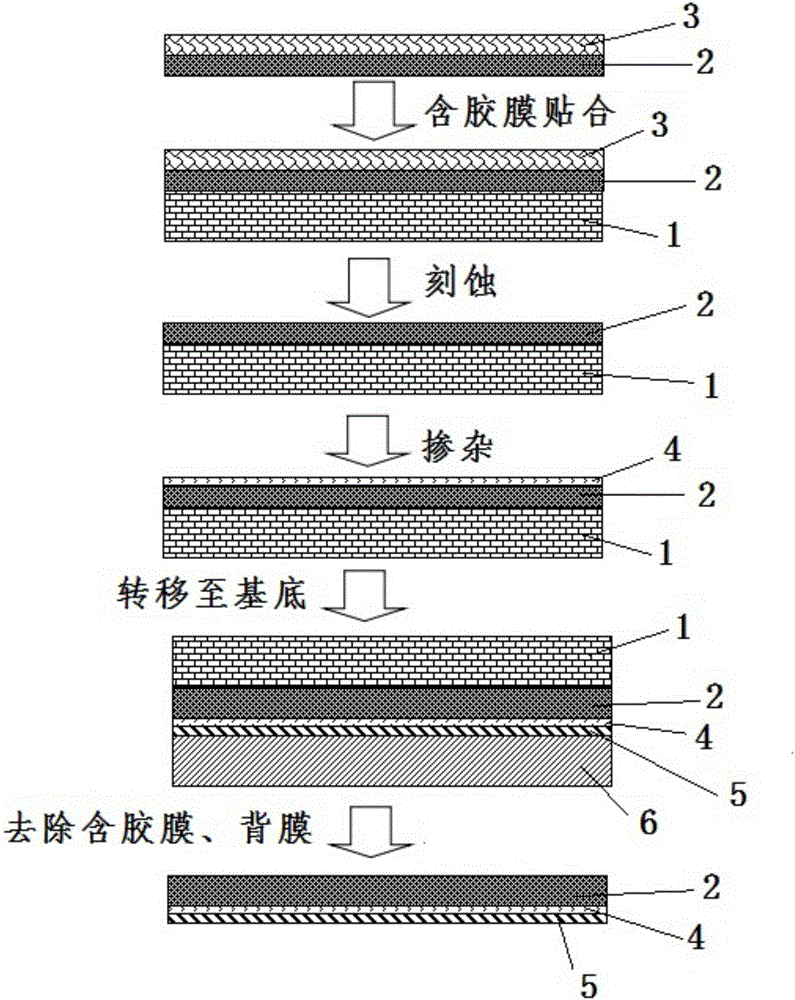

[0052] For the preparation method of ultra-thin and ultra-flexible graphene conductive film, the process flow chart is shown in the appendix figure 1 :

[0053] 1. Lay the copper foil / graphene grown by CVD method and the silica gel film together to obtain the copper foil / graphene / silica gel film;

[0054] 2. Remove the copper foil by chemical etching, and at the same time dope the silica gel film / graphene, and use chloroauric acid to dope the graphene to obtain the silica gel film / graphene / Au;

[0055] 3. Lay the silicone film / graphene / Au on the ultra-thin PET with a back film. The thickness of the PET substrate is 20um, the material of the back film is pet, and the thickness is 100um. The ultra-thin PET / Au / graphite with a back film is obtained. Graphene / Silicone film, bake at 90°C for 10 minutes, take it out and peel off the Silicone film to obtain ultra-thin PET / Au / Graphene with backing film;

[0056] 4. Remove the above back film to obtain ultra-thin PET / Au / graphene;

[...

Embodiment 2

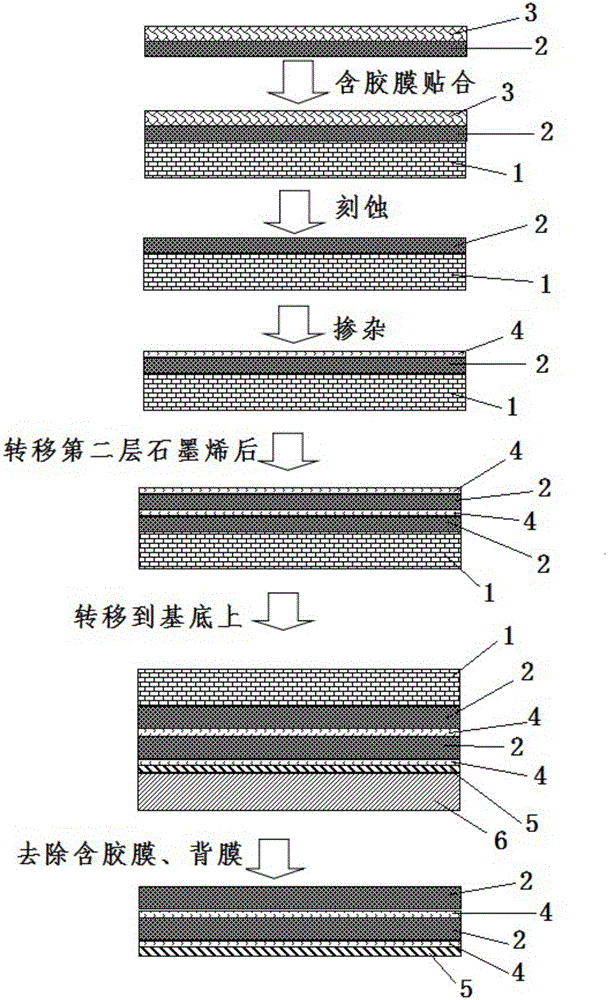

[0059] For the preparation method of ultra-thin and ultra-flexible graphene conductive film, the process flow chart is shown in the appendix figure 2 :

[0060] 1. Lay the copper foil / graphene grown by CVD method and the silica gel film together to obtain the copper foil / graphene / silica gel film;

[0061] 2. Remove the copper foil by chemical etching, and dope the silica gel film / graphene at the same time, and dope the graphene with ferric chloride to obtain the silica gel film / graphene / Fe;

[0062] 3. Lay the silicone film / graphene / Fe on the ultra-thin PET with a back film. The thickness of the PET substrate is 10um, the material of the back film is pet, and the thickness is 100um. The ultra-thin PET / Fe / graphite with a back film is obtained. Graphene / Silicone film, bake at 90°C for 10 minutes, take out and peel off the Silicone film to obtain ultra-thin PET / Fe / Graphene with backing film;

[0063] 4. Transfer the second layer of graphene according to the above method to obt...

Embodiment 3

[0067] For the preparation method of ultra-thin and ultra-flexible graphene conductive film, the process flow chart is shown in the appendix figure 2 :

[0068] 1. Bond the copper foil / graphene grown by CVD method with the PMMA film to obtain the copper foil / graphene / PMMA film;

[0069] 2. Remove the copper foil by chemical etching to obtain PMMA film / graphene;

[0070] 3. Bond the PMMA film / graphene to the ultra-thin PEN with a back film. The thickness of the PEN substrate is 15um, the material of the back film is pet, and the thickness is 120um. The ultra-thin PEN / graphene / PMMA with a back film is obtained. For the adhesive film, use a laminating machine to roll it at 120 degrees for 2 times, then take it out and peel off the PMMA adhesive film to obtain ultra-thin PEN / graphene with a backing film;

[0071] 4. Transfer the second layer of graphene according to the above method to obtain ultra-thin PEN / graphene / graphene with back film;

[0072] 5. Remove the above back fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com