A combined tooling for processing a variable-diameter cylinder on a heavy-duty floor lathe

A floor lathe and cylinder technology, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem of affecting the coordination accuracy of the overall assembly transmission stability of the cylinder, the inability to meet the processing needs of the cylinder, and poor processing stability, etc. problems, to achieve the effect of considerable prospects, high rigidity, and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

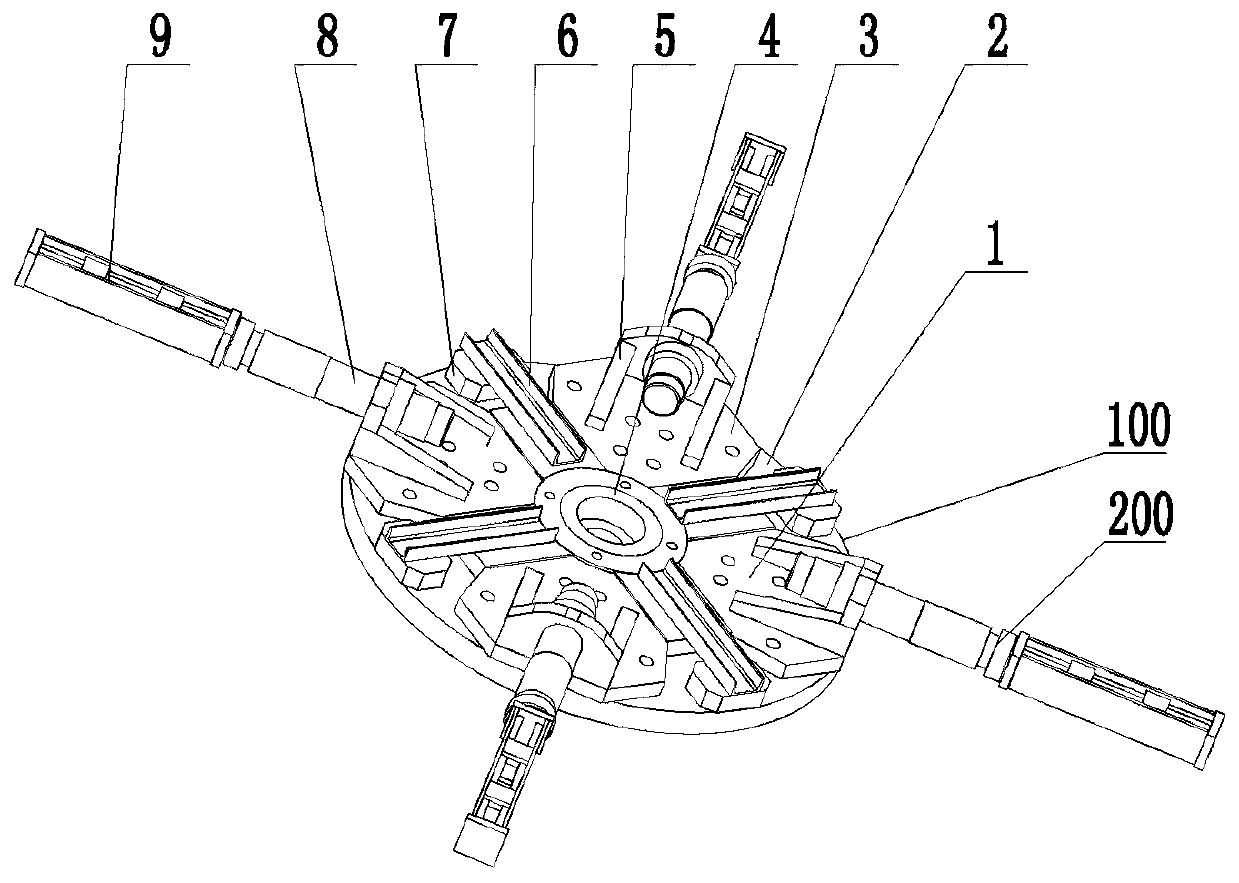

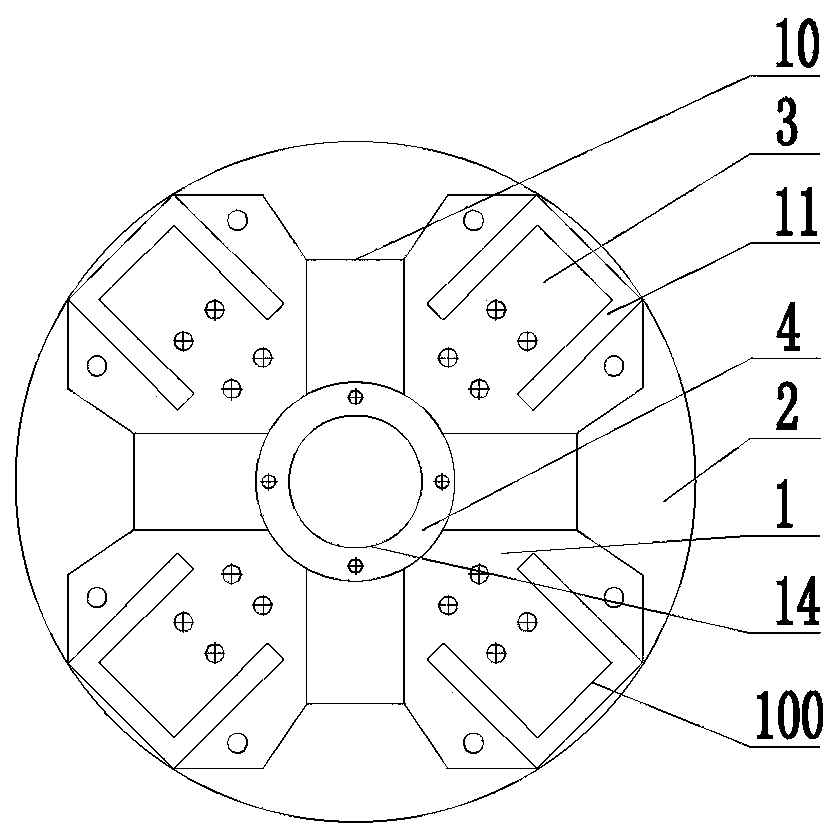

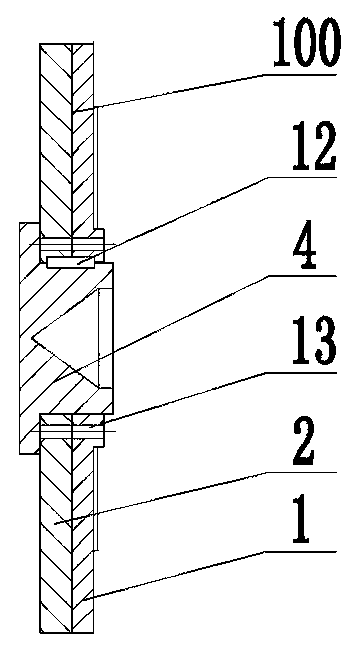

[0025] The present invention includes a positioning device 100, a supporting device 200 is arranged on the positioning device 100, and it is characterized in that: the positioning device 100 includes a base plate 2, and a positioning plate 1 is fixedly arranged on the base plate 2 through a bolt assembly, and the base plate 2 The center of the positioning plate 1 is provided with a corresponding mounting hole 14; the mounting hole 14 is provided with a positioning plug 4 that can cooperate with the top of the machine tool, and a connecting key 12 is provided between the positioning plug 4 and the mounting hole 14; the supporting device 200 includes support bases 5 that are evenly distributed around the circumference and fixed on the positioning plate 1 . Adjusting studs 8 are threaded on the support base 5 , and support blocks 9 are provided at the ends of the adjustment studs 8 .

[0026] As a preferred solution of the present invention, the outer edge of the positioning plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com