Deepwater diamond wire sawing machine

A diamond wire saw machine, deep water technology, applied in the direction of metal sawing equipment, sawing machine, metal processing equipment, etc., can solve the problems of operator injury, narrow range of cutting pipe diameter, and reduced service life of beaded rope, so as to ensure the cutting capacity , It is convenient for underwater operation and the driving efficiency is enhanced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

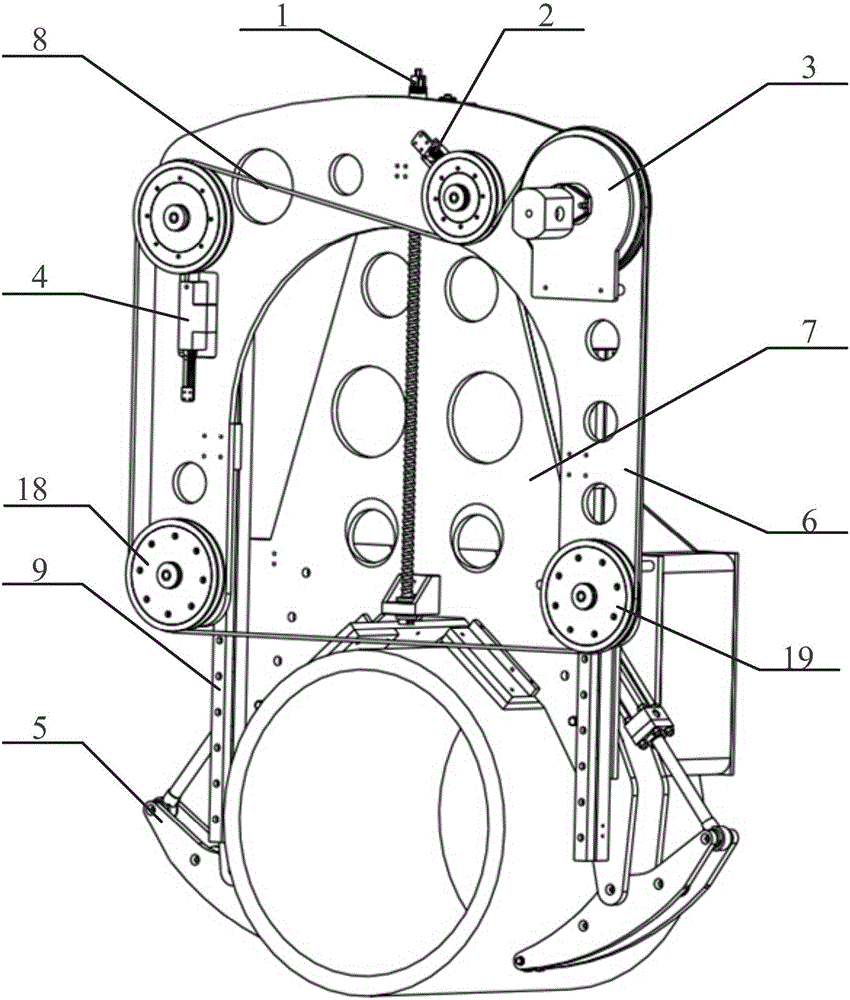

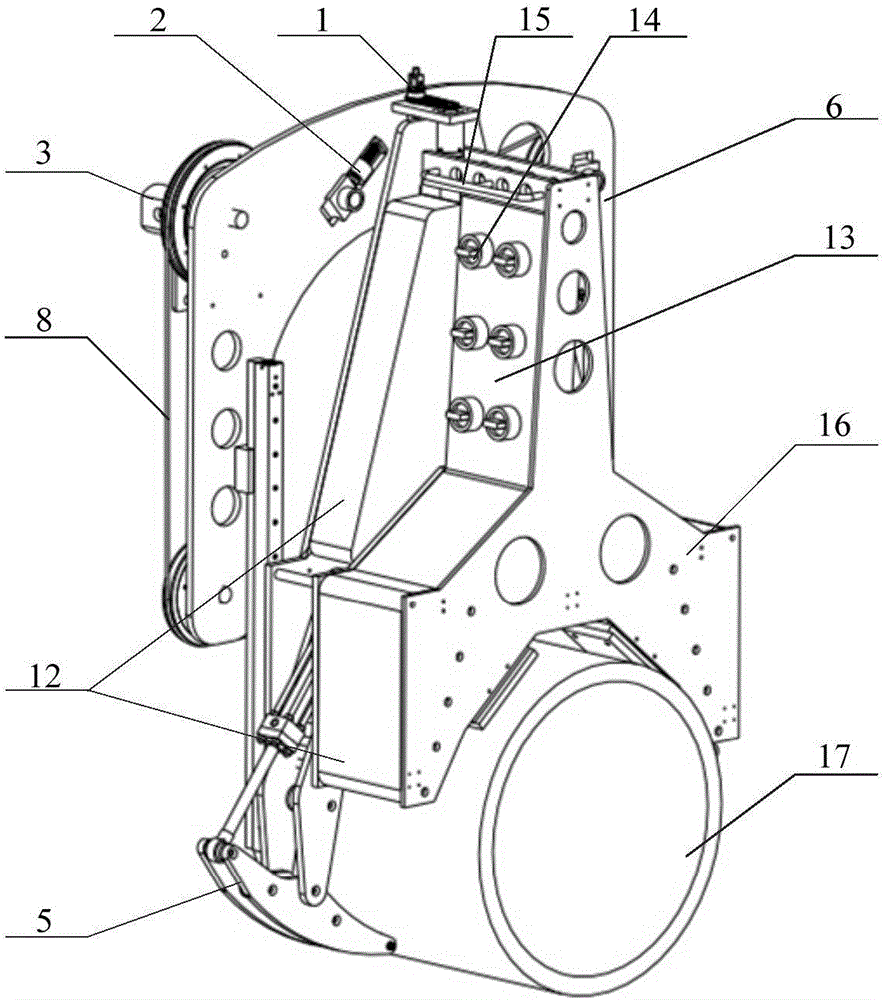

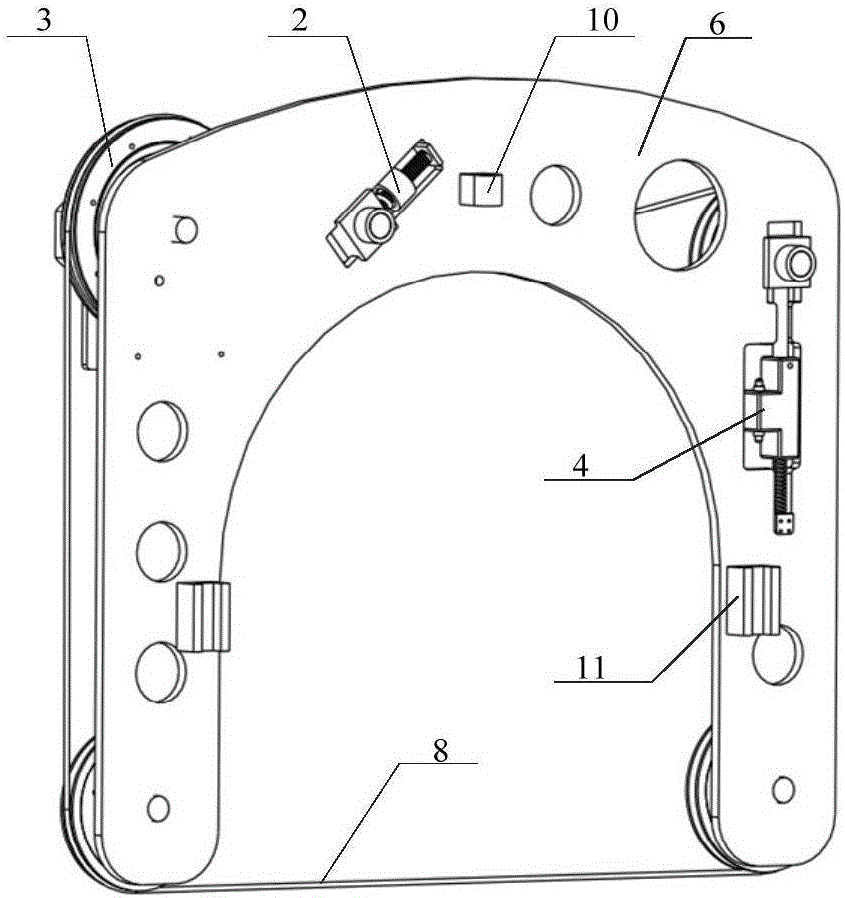

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, it is mainly composed of a feed drive mechanism 1, a beaded rope tension mechanism 2, a cutting drive mechanism 3, a feed speed adjustment mechanism 4 and a clamping mechanism 5. The feed drive mechanism 1 is installed in the middle of the lower bracket 7 with screws , is connected with the upper bracket 6 through the screw 110 and the screw nut 10, and can slide up and down along the two guide rails 9 fixed on both sides of the lower bracket 6. The beaded rope tensioning mechanism 2, the feed speed adjustment mechanism 4 and the cutting drive mechanism 3 Installed on the upper bracket 6, a beaded rope 8 is connected with the driven wheel 401 tensioning wheel 201, two driving wheels 18 and 19 and a driving wheel 301, the clamping mechanism 5 is integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com