Device and method for obtaining air from water

An air and decompression device technology, applied in separation methods, chemical instruments and methods, liquid degassing, etc., can solve the problems of bulky submarines and divers, and the limitation of underwater operation time of oxygen cylinder divers, so as to save costs and avoid dangers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

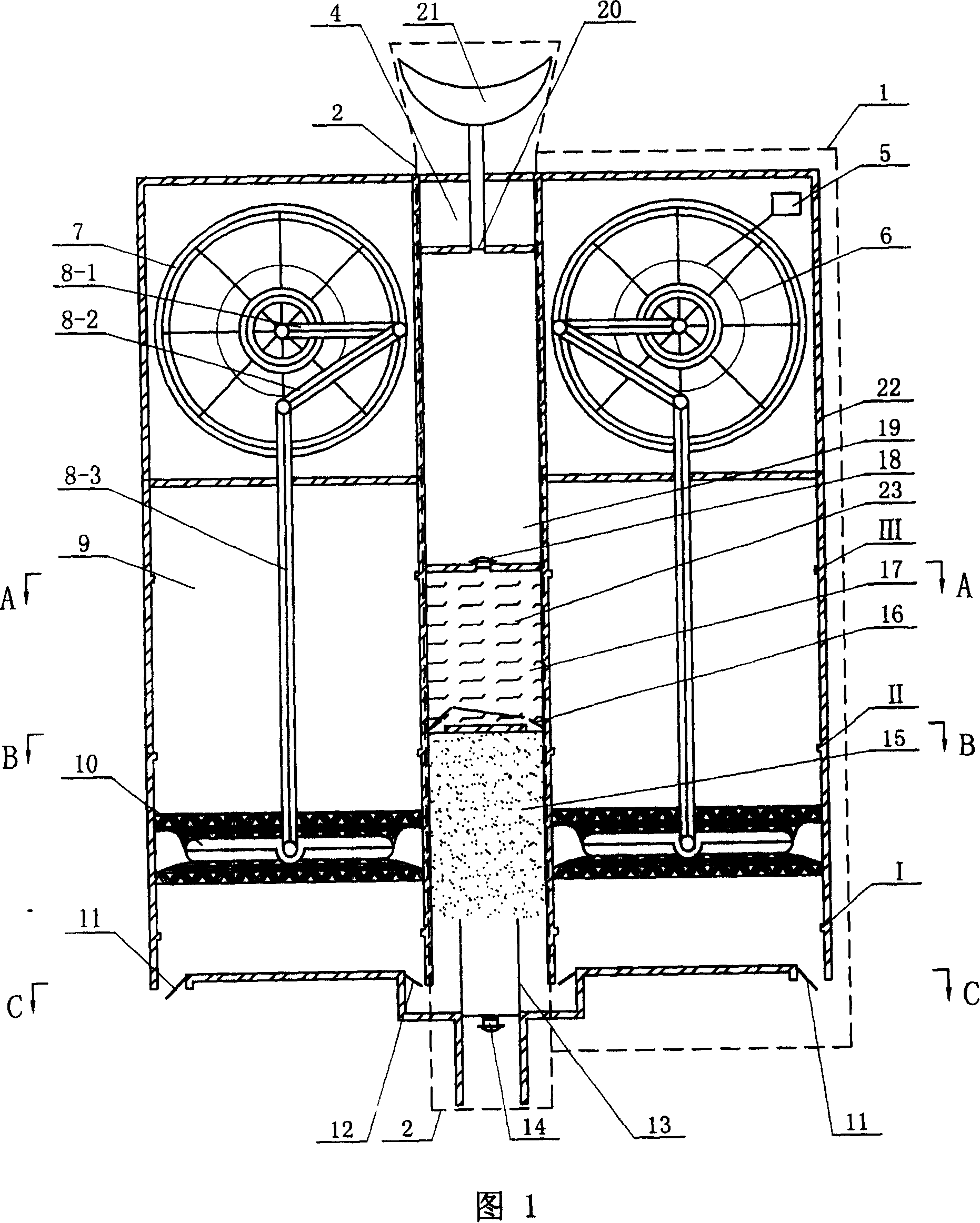

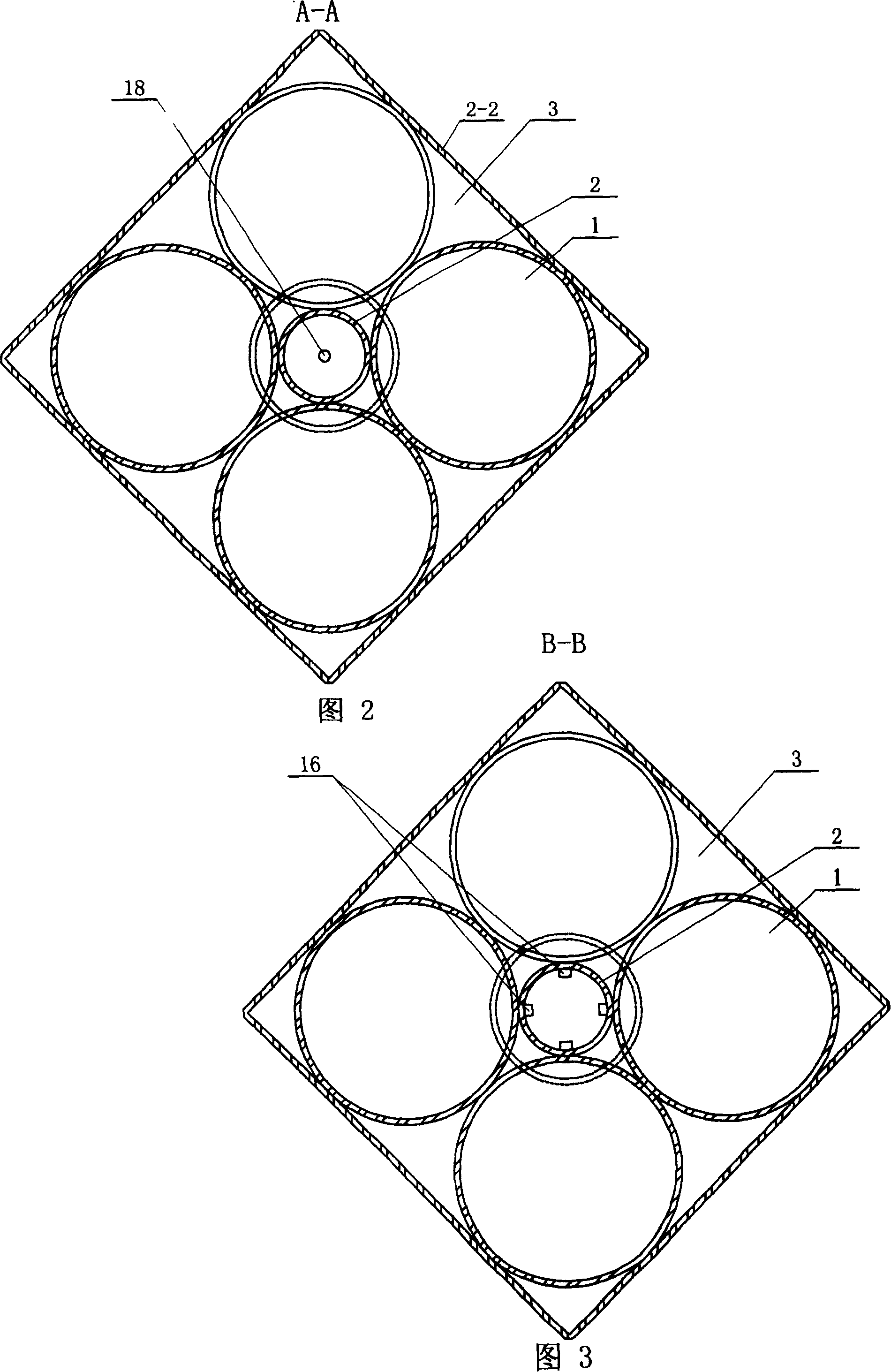

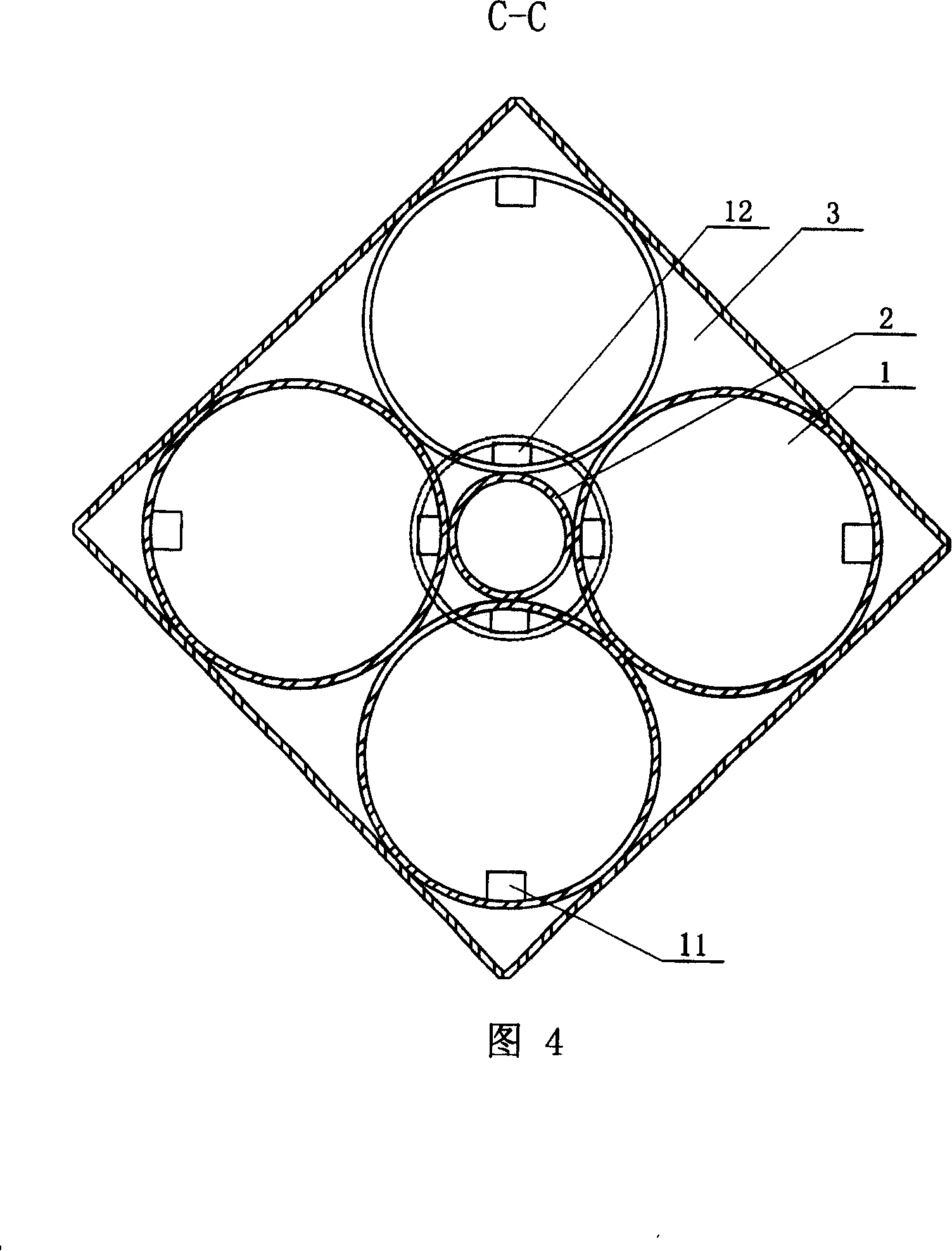

[0013] Embodiment 1: The device for obtaining air from water in this embodiment is composed of a decompression device 1, a gas collection and storage discharge device 2 and a valve control mechanism 3. The decompression device 1 can adopt N according to the amount of gas required, reducing the pressure. The pressure device 1 is connected with the gas collection, storage and discharge device 2 through the one-way valve 12 of the gas-water separation chamber, and the valve control mechanism 3 is arranged between the housing 22 and the decompression device 1 (see FIG. 2 ). The valve control mechanism 3 adopts an electromagnetic The valves are respectively connected with the one-way valve 11 of the water inlet and the one-way valve 12 of the air-water separation chamber, and the one-way valve 11 of the water inlet and the one-way valve 12 of the air-water separation chamber adopt a one-way stroke switch.

specific Embodiment approach 2

[0014] Specific embodiment two: the decompression device 1 of the present embodiment is composed of a power supply 5, a motor 6, a crank connecting rod runner mechanism 7, a connecting rod 8, a main reaction chamber 9, a piston 10 and a water inlet one-way valve 11, reducing Compression device 1 adopts four (see Fig. 2), and the output shaft of the motor 6 that is arranged on decompression device 1 top is connected with the input shaft of crank link runner mechanism 7, and the output shaft of crank link runner mechanism 7 It is connected with one end of the first connecting rod 8-1, the other end of the first connecting rod 8-1 is connected with one end of the second connecting rod 8-2, and the other end of the second connecting rod 8-2 is connected with the third connecting rod 8 The upper end of -3 is connected, the lower end of the third connecting rod 8-3 is connected with the piston 10 in the main reaction chamber 9, and the main reaction chamber 9 is at the bottom of the ...

specific Embodiment approach 3

[0015] Specific embodiment three: the gas collection, storage and discharge device 2 of this embodiment (see Figure 1) includes a baffle 13, a one-way drain valve 14, a gas-water separation chamber 15, an air intake one-way valve 16, a gas purification chamber 17, a storage Air chamber intake one-way valve 18, air storage chamber 19, air outlet valve 20 and respirator 21, gas-water separation chamber 15 is provided at the bottom of gas collection storage discharge device 2, and the bottom of gas-water separation chamber 15 is provided with a stopper. Plate 13 and one-way drain valve 14, the upper top of the gas-water separation chamber 15 is provided with an air intake one-way valve 16, the top of the air intake one-way valve 16 is provided with a gas purification chamber 17, and the gas purification chamber 17 is built with a polymer Active material 23, the upper top place of gas purification chamber 17 is provided with gas storage chamber inlet check valve 18, and the top of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com