A modular underwater vertical diamond wire saw machine

A diamond wire saw machine, modular technology, applied in the field of ocean engineering, can solve the problems of limiting the flexibility and application range of underwater operations, the large size of the wire saw machine, and the inability to replace the beaded rope in time, so as to achieve a compact overall structure of the machine tool, The effect of simplifying the feed structure and facilitating underwater operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] The purpose of the present invention is achieved like this:

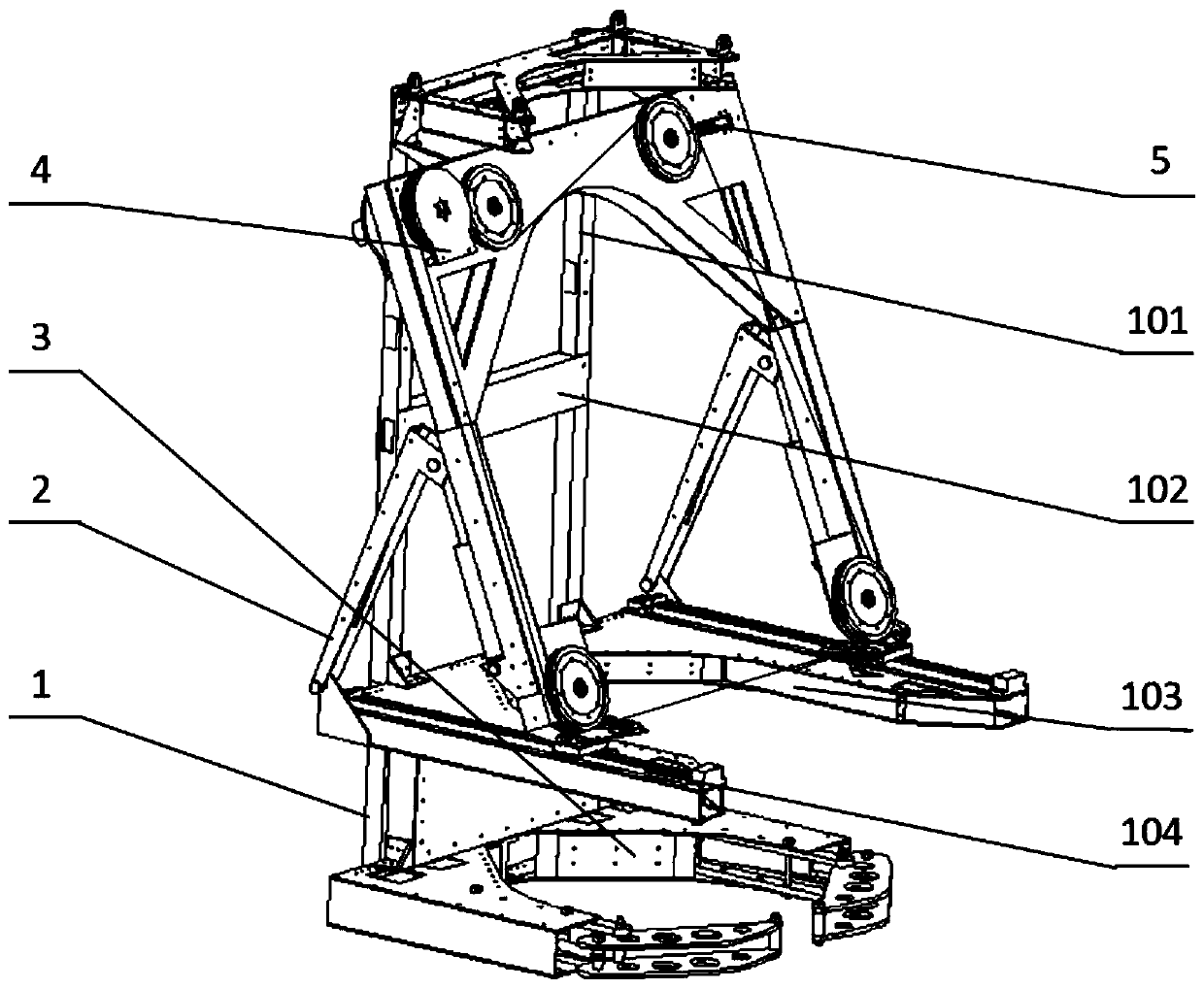

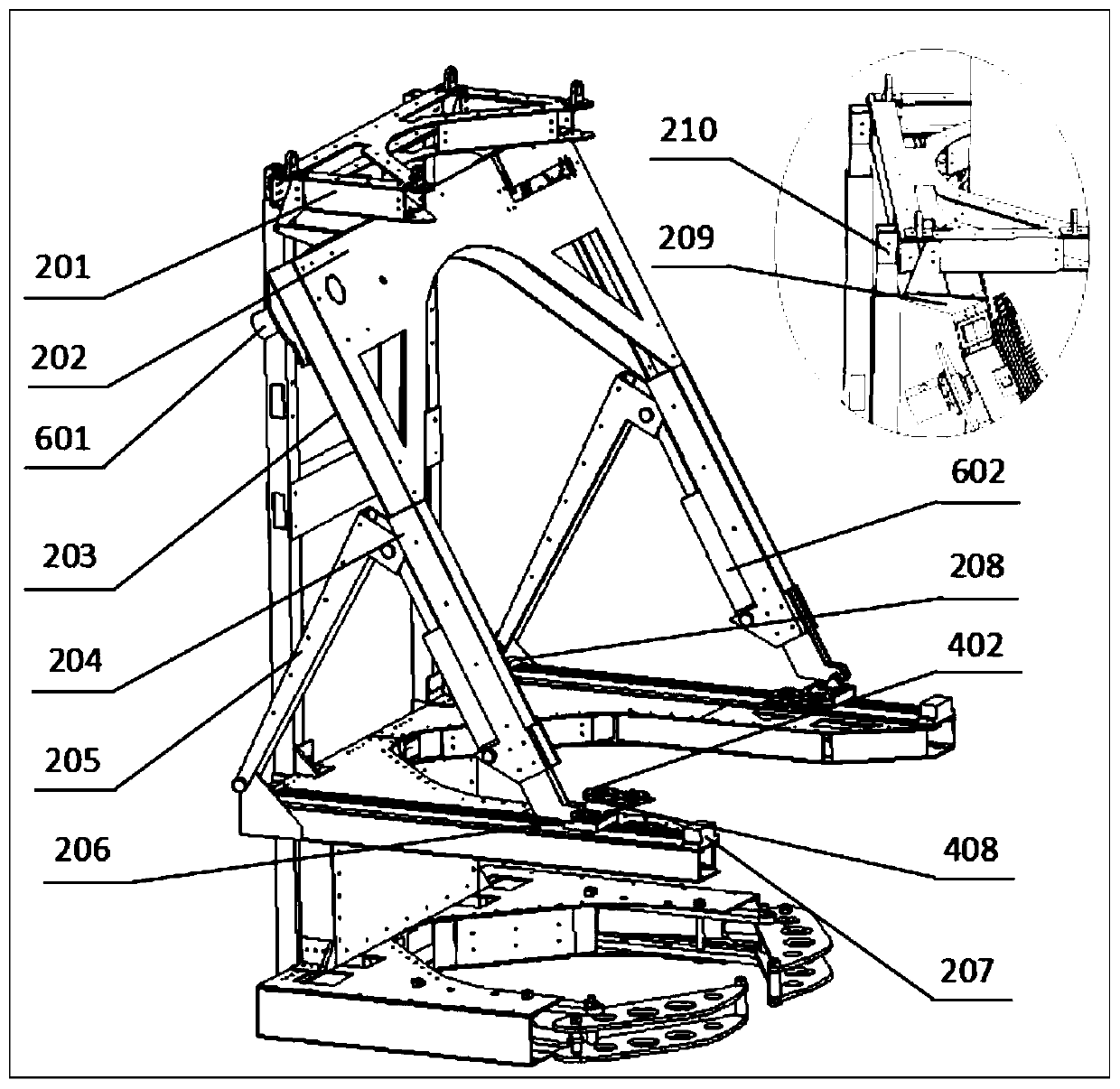

[0024] Consists of a whole frame with support back plate, reinforcement ribs, floor frame and two guide rails, feeding device consisting of feeding rear part and feeding front part, cutting device consisting of detachable parts and fixed parts , a tensioning device consisting of detachable and non-detachable components, and a clamping and fixing device vertically installed at the bottom of the supporting backplane and connected to the reinforcing ribs.

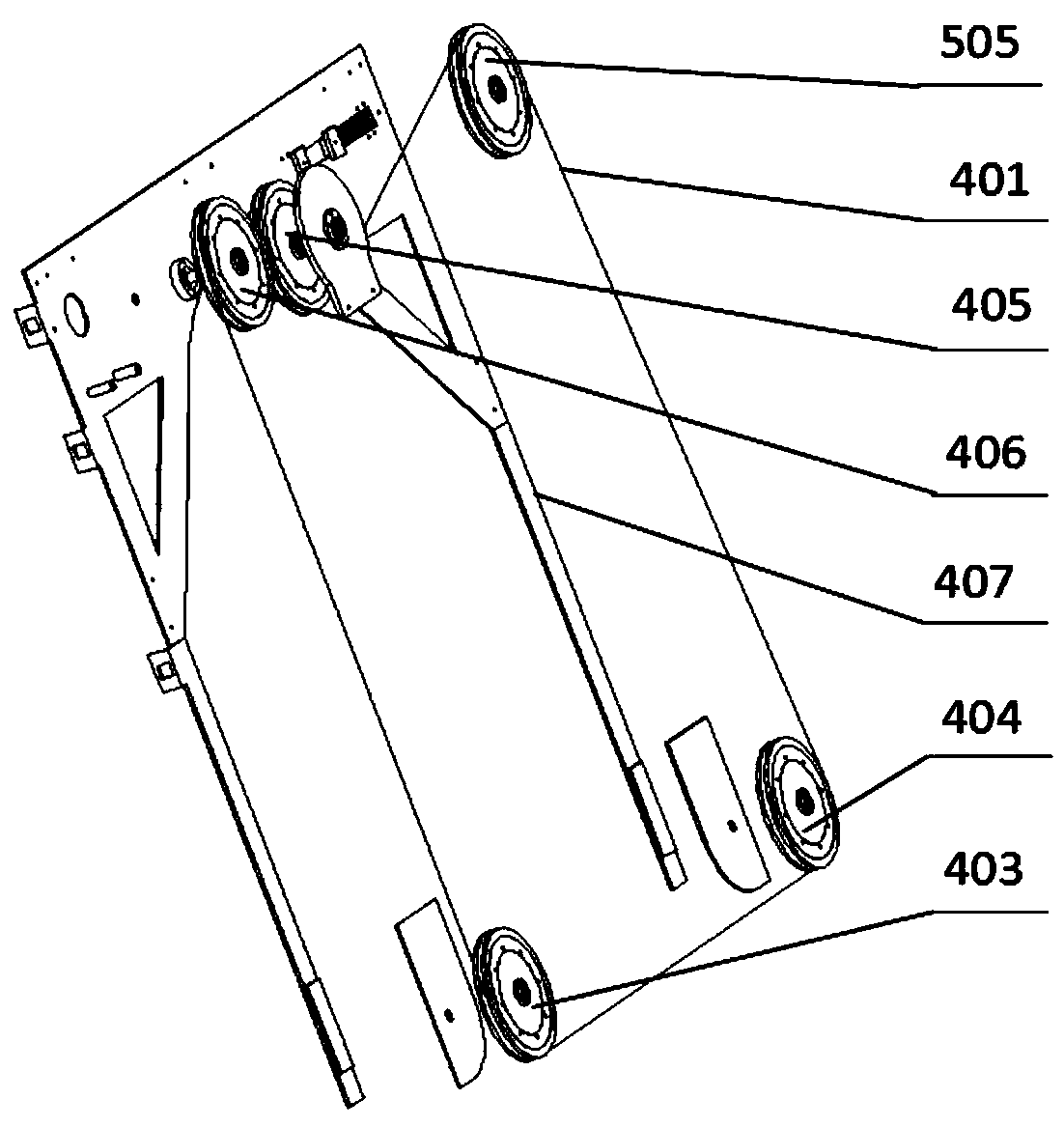

[0025] The feed device includes: feed front plate, feed rear plate, side frame, guide rail, push rod, feed hydraulic cylinder, travel switch, limit block and slide rail frame. The side frame is hinged to the bottom of the cylinder barrel of the feed hydraulic cylinder, and the piston rod of the hydraulic cylinder is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com