Numerical control engraving and milling machine tool for processing end surface of slender rod workpiece

A technology for slender rods and workpieces, which is applied in the field of CNC engraving and milling machine tools for processing the end faces of slender rod workpieces. It can solve problems such as the instability of drill bit motors, and achieve the effects of low manufacturing cost, easy use, and simple and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

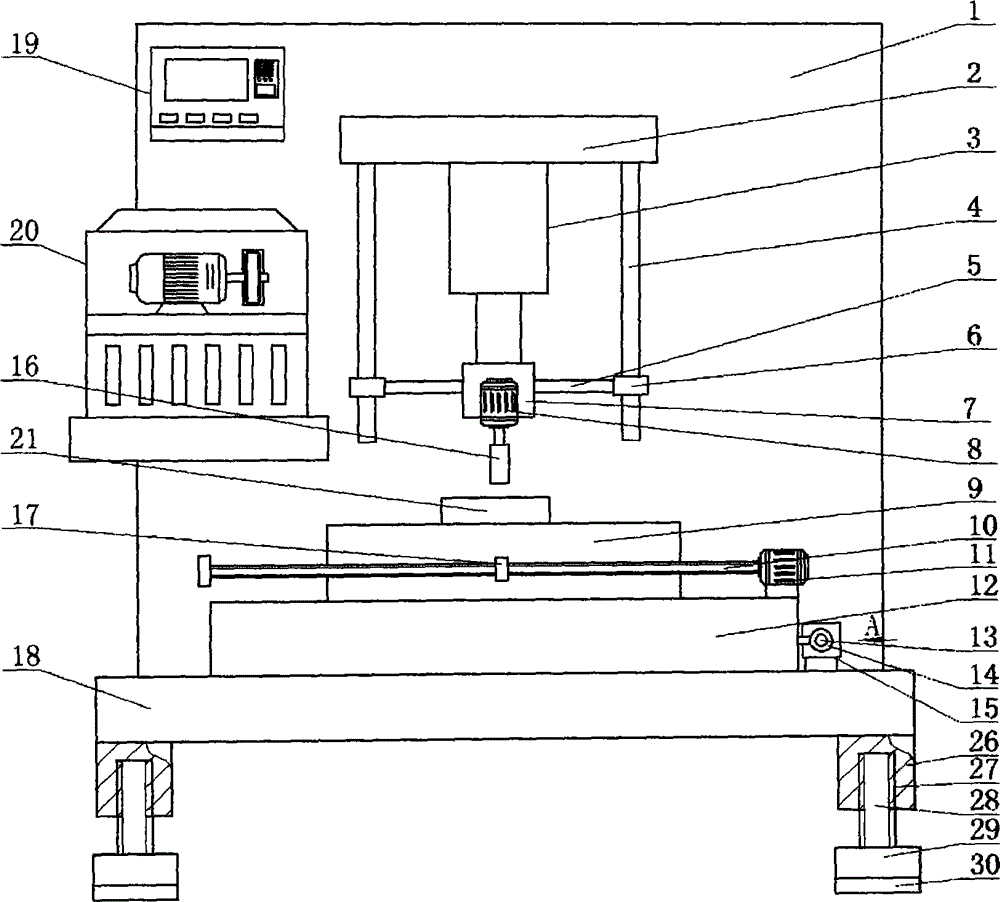

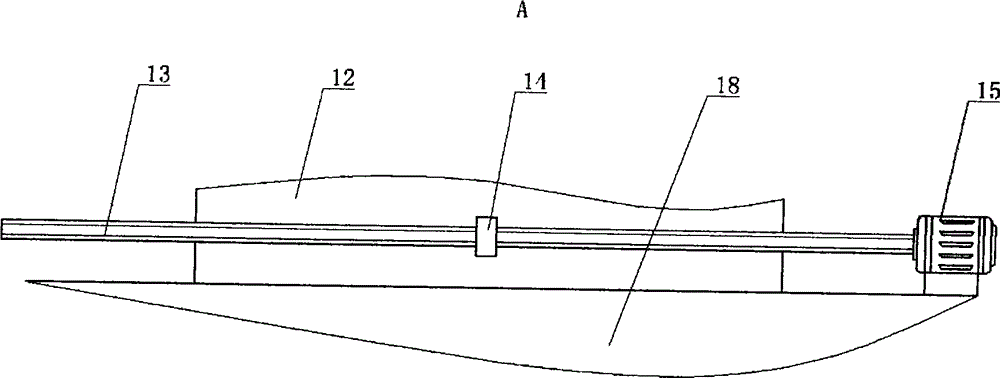

[0012] A CNC engraving and milling machine tool for processing the end face of a slender rod workpiece, such as figure 1 and figure 2 As shown, the base 18 is included, the top of the base 18 is provided with a first sliding plate 12, the first sliding plate 12 can slide on the base 18, the first nut 14 is installed on one side of the first sliding plate 12, and the first nut 14 is installed on one side of the base 18. The first stepping motor 15, the first screw mandrel 13 is installed on the output shaft of the first stepping motor 15, the first screw mandrel 13 cooperates with the first nut 14, the top of the first sliding plate 12 is provided with the second sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com