A kind of catalyst and its preparation method for dns hydrogenation reduction preparation das

A technology of catalysts and carbon catalysts, applied in catalyst protection, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of high selectivity that has not been reported in literature, catalyst life is impossible to talk about, Heavy metals pollute the reaction liquid and other problems, achieve the effects of improving life, ecology and environment friendliness, and solving low selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

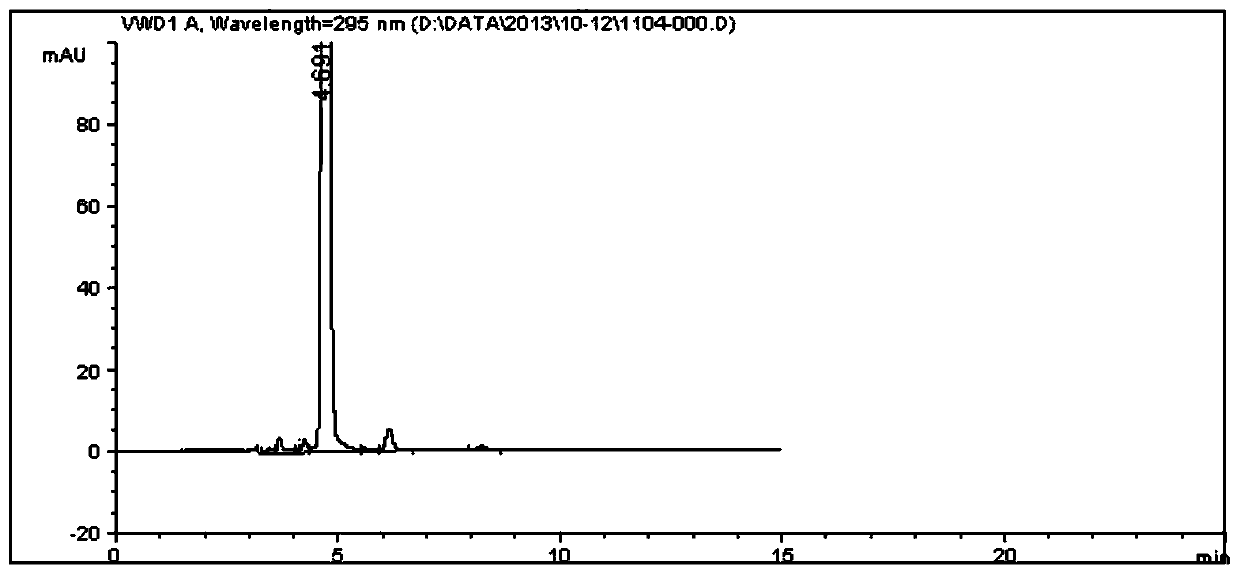

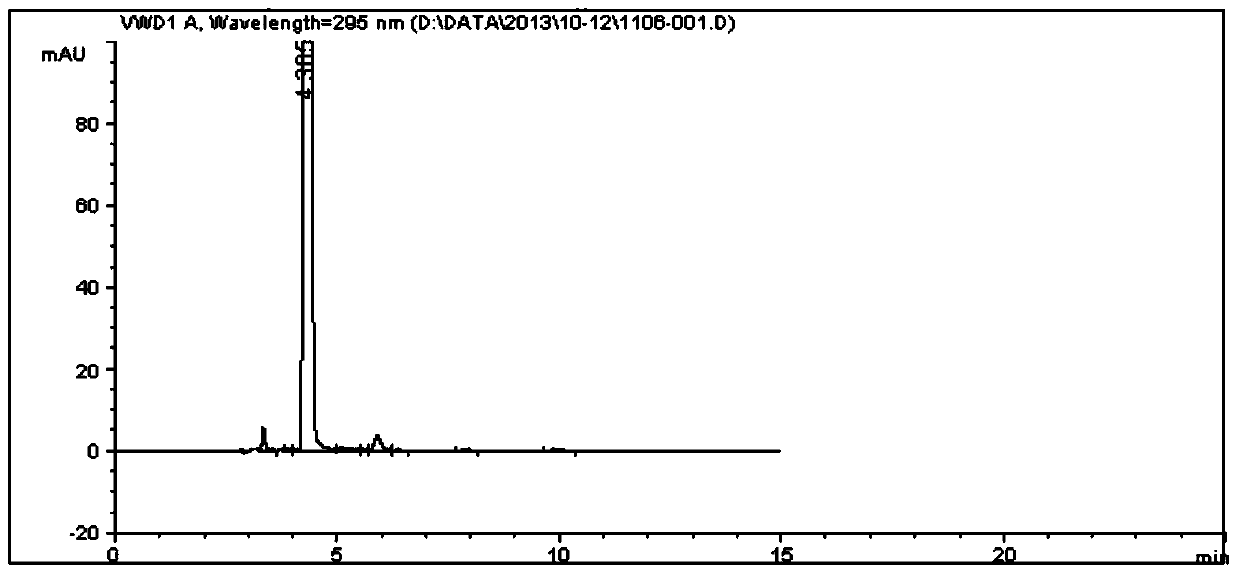

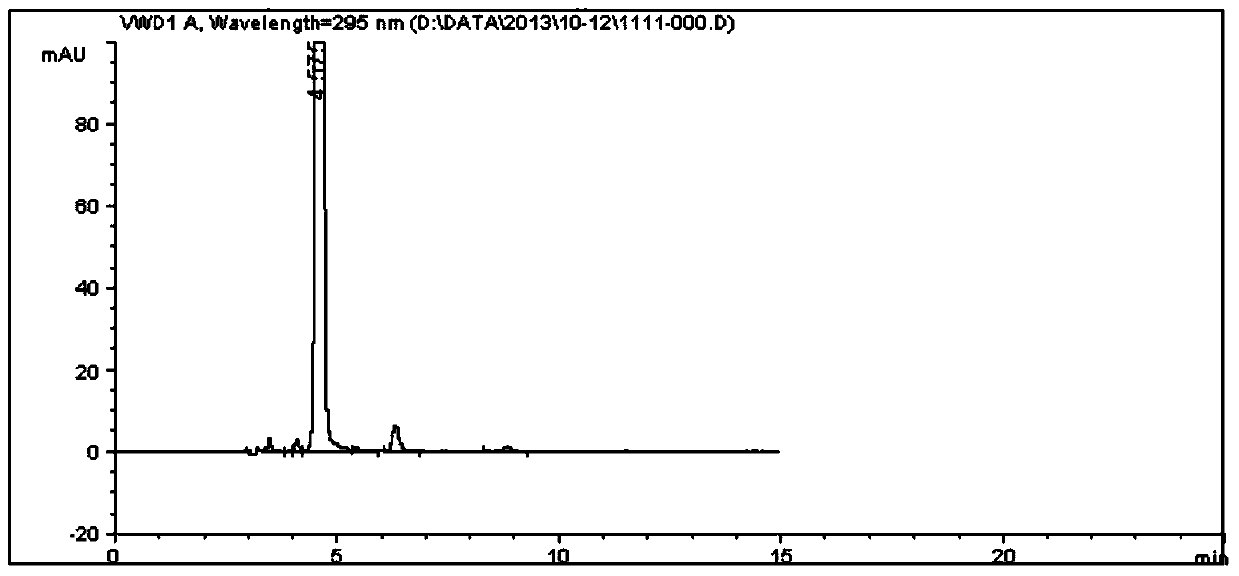

Image

Examples

Embodiment 1

[0042] Catalyst preparation:

[0043] 1. Weigh 10.0g (dried product) of Pd / C (Typ37 3% Pd) catalyst from Johnson Matthey Company, put it in a 250ml four-necked bottle, add 100ml pure water, and add 10% PVP (3000) aqueous solution under stirring 0.3g; heat up to 45°C, add 0.7ml of 0.2M lead acetate aqueous solution, 0.7ml of 0.2M bismuth trichloride hydrochloric acid solution, and 1.4ml of 0.2M potassium chromium sulfate aqueous solution.

[0044] 2. After the addition, slowly raise the temperature to 80°C, add 10ml of 10% sodium formate, then rapidly raise the temperature to reflux, and keep the first bulb at reflux. After refluxing for 3 hours, cool to 30°C and filter with suction. The filter cake was put into a vacuum drying oven at 105°C for vacuum drying, and after 3 hours, the power was turned off and cooled naturally. The next morning, the vacuum was lifted to take out the catalyst, and put it in a desiccator for later use.

[0045] The specific method of preparing DA...

Embodiment 2

[0048] The preparation method of self-made Pd / C: Weigh 35.0g of activated carbon (pre-activated) into a 1000ml four-necked flask, add 700ml of pure water at about 70°C, stir and heat up, add 7.0g of 10% PEG600 aqueous solution, and heat up to 80°C ℃, add 28.3ml of 0.4M palladium chloride hydrochloric acid solution, quickly add 15ml of formaldehyde solution under stirring, add 6.86% NaOH solution to adjust the pH value to 9.0. After adjustment, keep warm at 80°C for 0.5 hours. Filter and wash the filter cake repeatedly until the pH of the washing filtrate is neutral. After pumping, the filter cake was dried in the air at room temperature, and then dried in a desiccator filled with potassium hydroxide to obtain a dried catalyst, which was stored in a sealed bottle for future use.

[0049] Catalyst preparation:

[0050] 1. Weigh 34.9g of self-made Pd / C (3.44%Pd) catalyst, put it in a 1000ml four-necked flask, add 700ml of pure water, and add 0.7g of 10% PEG1500 aqueous solution...

Embodiment 3

[0055] Catalyst preparation:

[0056] 1. Weigh 34.9g of self-made Pd / C catalyst, put it in a 1000ml four-necked flask, add 700ml of pure water, and add 0.2g of 10% LAS aqueous solution under stirring. Heat up to 65°C, add 0.4ml of 0.2M lead acetate aqueous solution, 0.7ml of 0.2M potassium chromate solution, and 1.0ml of 0.2M sodium tungstate aqueous solution in sequence.

[0057] 2. After the addition, the temperature was raised to reflux, and 1.5ml of formic acid solution was carefully added. After reflux for 4.5 hours, cool to 30°C and filter with suction. After the filter cake is fully washed, it is placed in a vacuum drying oven for 2 hours at 65°C, 2 hours at 95°C, and 2 hours at 105°C.

[0058] The specific method of preparing DAS by DNS hydrogenation reduction is as follows:

[0059] Add 7.00g of hydrogenation catalyst, 600g of 18% DNS solution, a little flushing water to a 1L autoclave in sequence, seal the autoclave, first evacuate it, and when the vacuum degree r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com