Device and method for producing a three-dimensional object layer by layer

A technology for three-dimensional objects and equipment, applied in the directions of processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve problems such as the impact on the quality of the object to be manufactured, the uneven transport of smoke and steam, and the impact on the quality of the object to be manufactured, and achieve laminar flow improvement , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

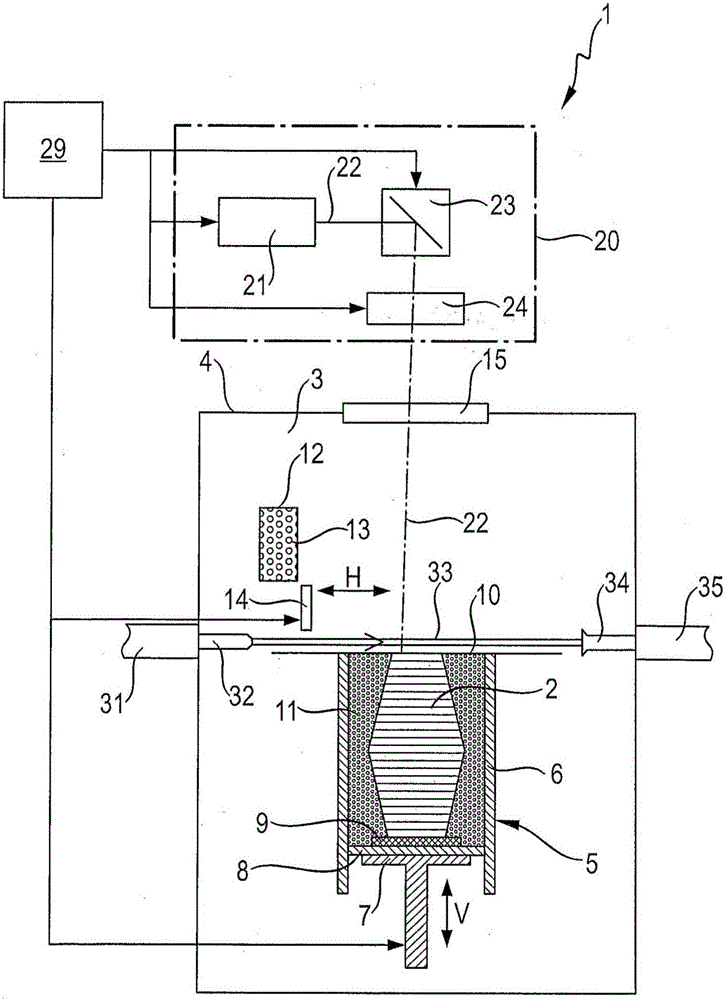

[0025] Refer below Figure 1 to Figure 5 An example of the apparatus according to the first embodiment of the present invention is described. exist figure 1 The device shown in is a laser sintering or laser melting device 1 . For forming the object 2 the device comprises a treatment chamber 3 with a chamber wall 4 .

[0026] An upwardly open container 5 with a wall 6 is provided in the treatment chamber 3 . A support 7 movable in the vertical direction V is provided in the container 5 , on which a base plate 8 is mounted, which closes the container downwards and thus forms the bottom of the container. The base plate 8 may be a plate constructed separately from the support 7 and fastened thereto, or it may be constructed integrally with the support 7 . Depending on the powder and the process used, it is also possible to mount a build platform 9 on the base plate 8 on which the object 2 is built. However, the object 2 can also be constructed on the substrate 8 itself, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com