Preparation method of silver nanowire graphene oxide composite conductive thin film heater

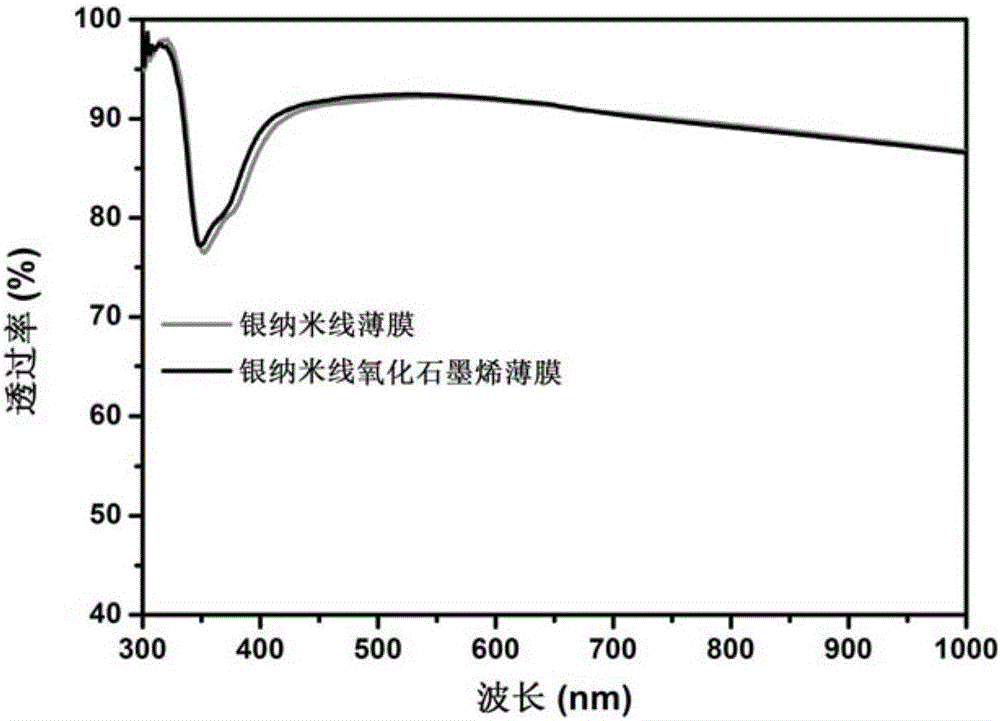

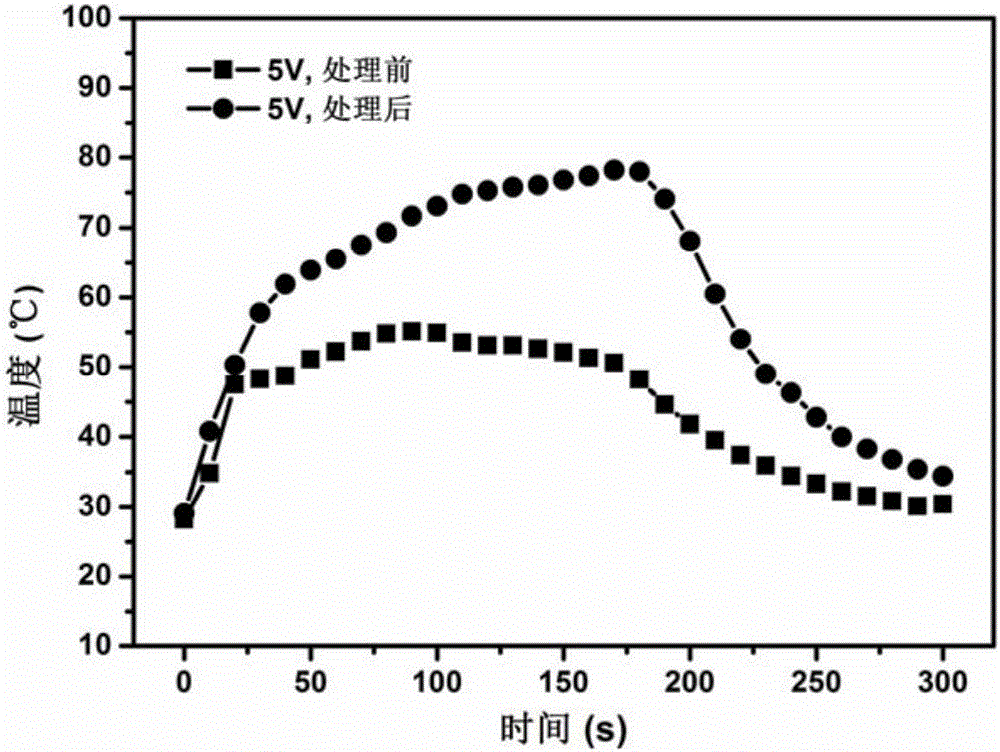

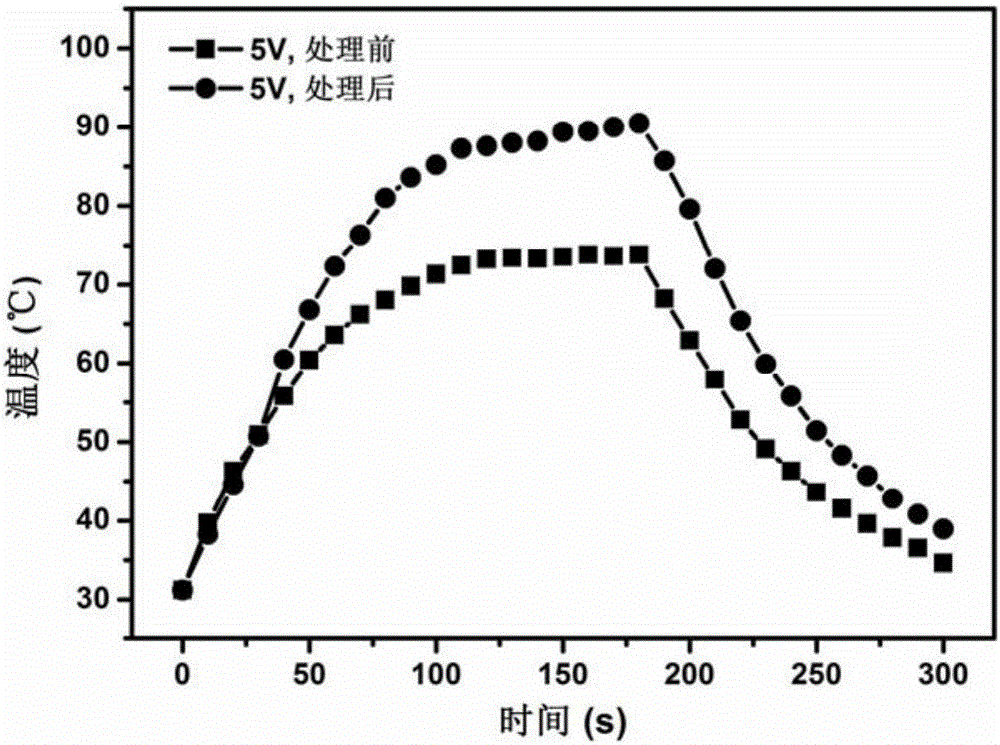

A graphene composite, silver nanowire technology, applied in ohmic resistance heating, electric heating devices, heating element materials, etc., can solve problems such as poor film conductivity, achieve low cost, increase heating temperature, and enhance the effect of heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of silver nanowire ethanol solution comprises the following steps:

[0034] 1) Add 16ml of ethylene glycol, 0.01g of sodium bromide, and 0.66g of polyvinylpyrrolidone into the reactor, then stir and heat to 165°C. Finally add 0.05g of silver chloride, after reacting for 3min, slowly add 4ml of ethylene glycol solution containing 0.22g of silver nitrate, the dropping rate is 0.4ml / min, the reaction time is 30min, and cooled to room temperature to obtain silver nanometer mother liquor.

[0035] 2) Pour the silver nanowire mother liquor into a centrifuge tube, centrifuge at 2000rpm for 30min, discard the precipitate, keep the upper silver nanowire mother liquor, add ethanol with 4 times the volume of the silver nanowire mother liquor, and then centrifuge at 6000rpm and remove The supernatant was repeated three times, and finally the precipitate was extracted and dispersed with ethanol to obtain an ethanol solution of silver nanowires.

[0036] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com