Gallium nitride-based bismuth ferrite ferroelectric thin film and preparation method thereof

A gallium nitride-based ferrite and ferroelectric thin film technology, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, circuits, electrical components, etc., can solve problems such as hindering the epitaxial growth of BFO thin films, and achieve epitaxial integration , The effect of reducing the lattice mismatch degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

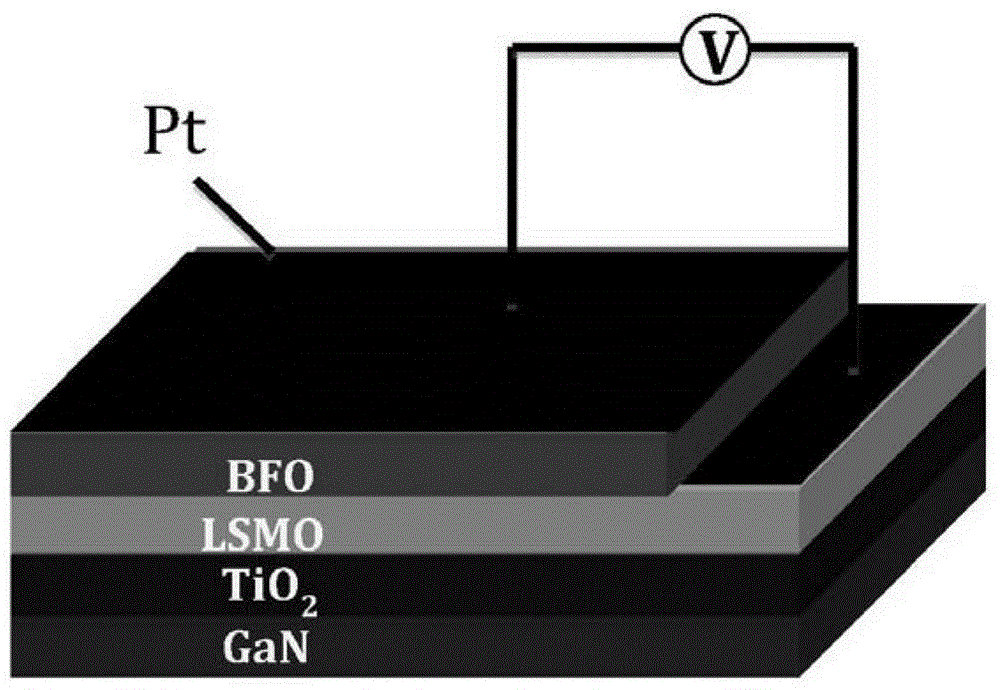

[0042] (1) Preparation of buffer layer: high-purity (≥99.99%) TiO 2 The ceramic block is used as the target, and the (0002) oriented GaN thin film substrate grown on the sapphire single crystal is placed in the reaction chamber of the pulsed laser deposition device, and the background is evacuated to ≦5×10 -4 Pa, and heated the substrate to 500°C at a heating rate of 5°C / min, and then evacuated the reaction chamber to 4×10 -4 Pa, deposition temperature 550℃, deposition oxygen pressure 0.001Pa, laser energy 5J / cm 2 , the distance between the substrate and the target is 5 cm, and the thin film is deposited to obtain TiO 2 Buffer layer with a thickness of 2nm. Then, with high purity (≥99.99%) La 0.7 Sr 0.3 MnO 3 The ceramic block is used as the target, the oxygen pressure is kept unchanged, the deposition temperature is raised to 750 °C, the deposition oxygen pressure is 30Pa, and the laser energy is 5J / cm 2 , the distance between the substrate and the target is 5cm, in TiO...

Embodiment 2

[0048] (1) The preparation process is basically the same as that in Example 1, except that in-situ annealing is not used, and the TiO 2 The buffer layer thickness is 2 nm, the thickness of the LSMO buffer layer is 8 nm, the BiFe 0.95 Mn 0.05 O 3 thin film with a thickness of 150nm;

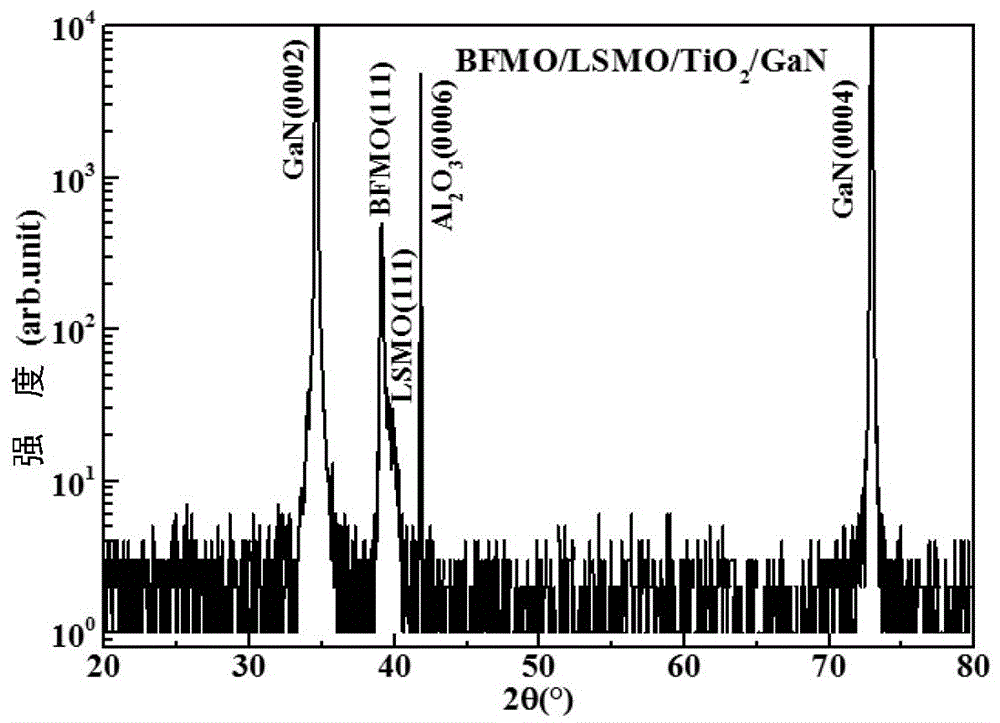

[0049] (2) Figure 7 BiFe prepared for Example 2 0.95 Mn 0.05 O 3 / LSMO / TiO 2 XRD pattern of / GaN heterojunction, it can be seen that BiFe 0.95 Mn 0.05 O 3 The film shows a strong perovskite structure (111) diffraction peak, but the half-peak width is wider, indicating that the BiFe prepared without in-situ annealing 0.95 Mn 0.05 O 3 The film has a single orientation, but the crystalline properties need to be improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com