Method for rapidly evaluating growth tendency of Sn crystal whiskers of Sn-based solder

A solder and whisker technology, applied in the field of rapid evaluation of Sn whisker growth tendency of Sn-based solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

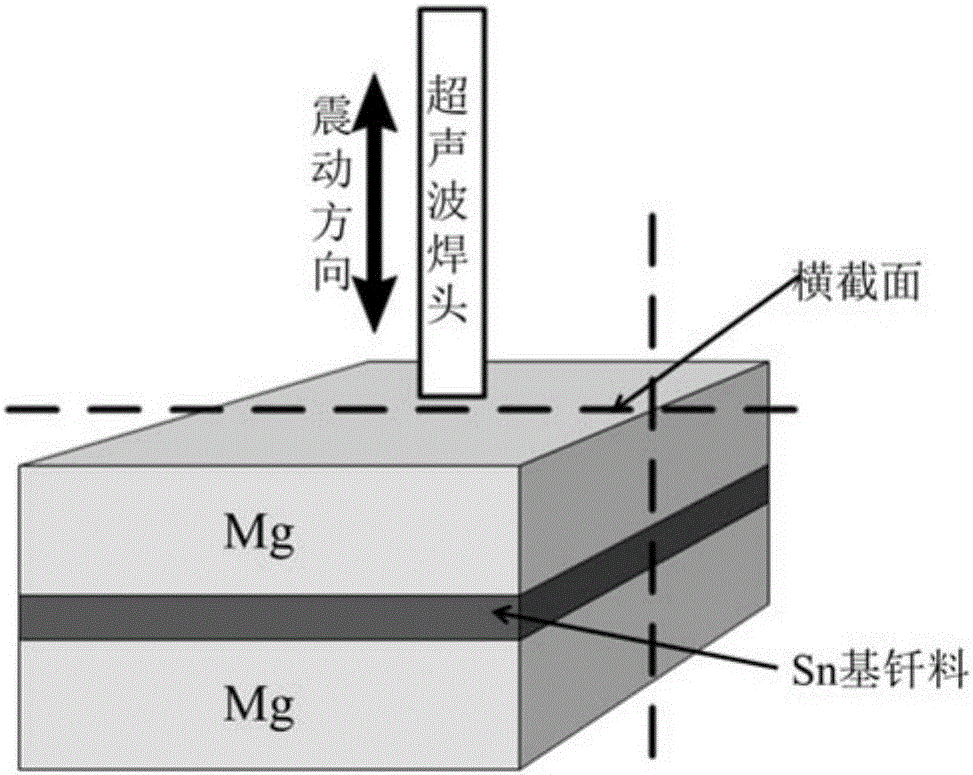

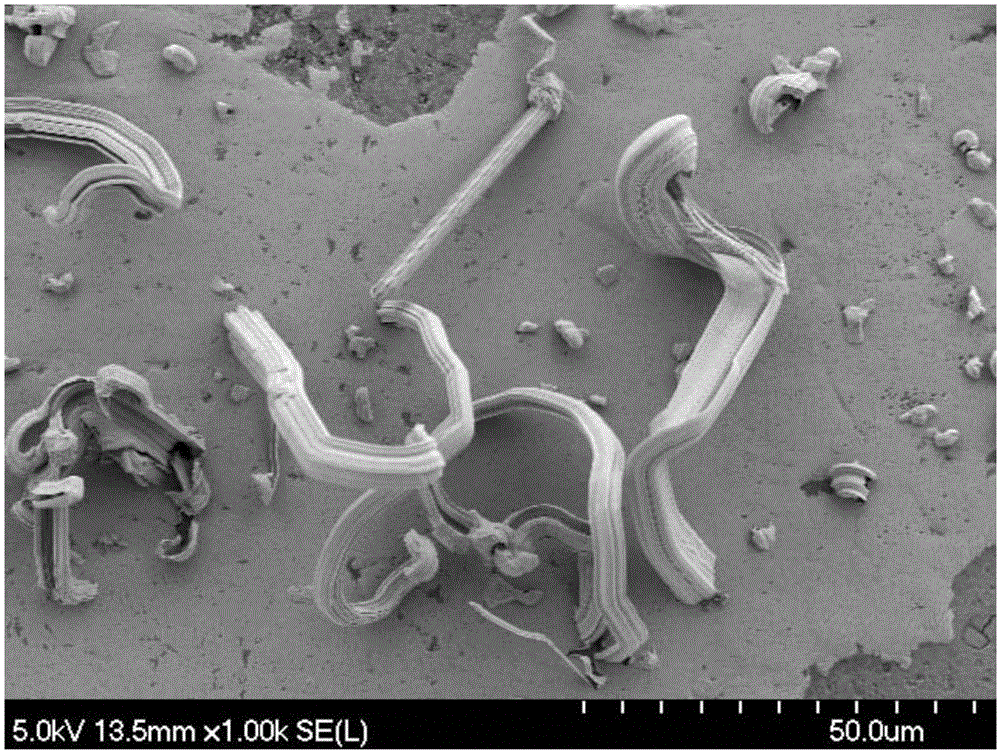

[0027] Such as figure 1 with 2 As shown, a 3mm thick pure Mg plate is selected, the pure Sn solder is pressed into a solder sheet with a thickness of 300μm, the weld width is 200μm, and the Mg / Sn / Mg sandwich structure is heated to 240°C by induction, and the operating frequency is 20KHz , an ultrasonic wave with an amplitude of 8 μm was applied for 15 s. After the sample is polished and placed in a room temperature environment (temperature 20-25°C, relative humidity 30-45% RH), Sn whiskers appear 2-4 hours after polishing, and then grow rapidly.

Embodiment 2

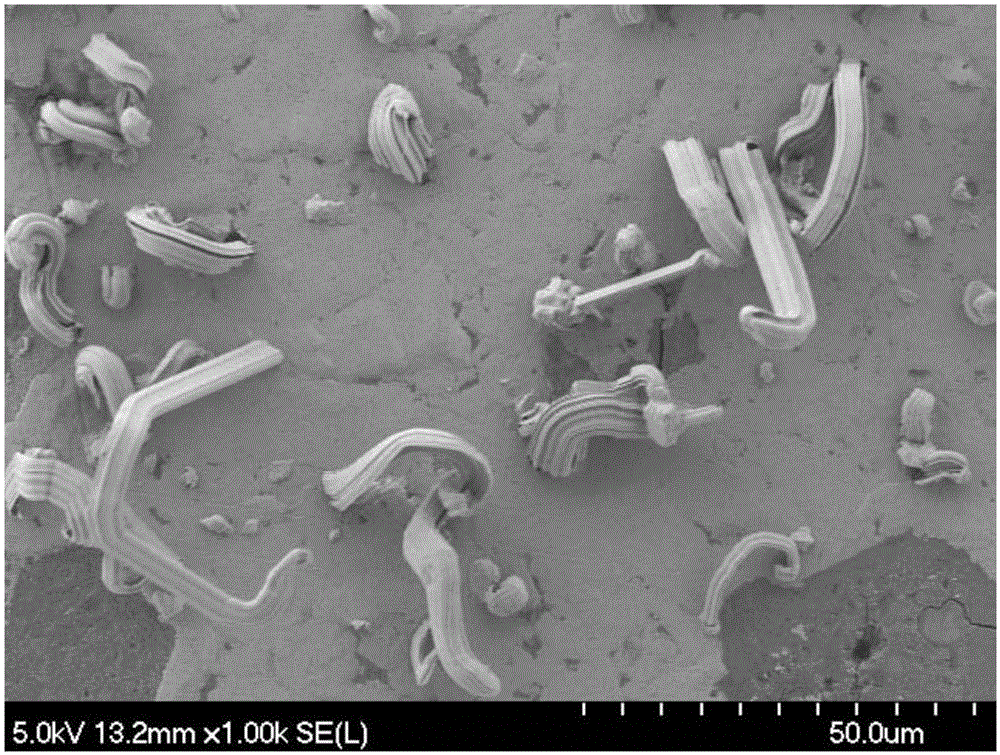

[0029] Such as figure 1 with 3 As shown, a 2mm thick pure Mg plate is selected, and the Sn-0.7Cu solder is pressed into a solder sheet with a thickness of 400μm, and the weld width is 300μm. The Mg / Sn / Mg sandwich structure is heated to 240°C by induction, and the frequency of use is Ultrasound at 20KHz with an amplitude of 5μm acts for 12s. After the sample is polished and placed in a room temperature environment (temperature 20-25°C, relative humidity 30-45% RH), Sn whiskers appear 2-4 hours after polishing, and then grow rapidly.

Embodiment 3

[0031] Such as figure 1 with 4 As shown, a 5mm thick pure Mg plate is selected, and the Sn-3Ag-0.5Cu solder is pressed into a solder sheet with a thickness of 200 μm, and the weld width is 150 μm. The Mg / Sn / Mg sandwich structure is heated to 230 ° C by induction. Ultrasonic waves with a frequency of 25KHz and an amplitude of 10μm were used for 6s. After the sample is polished and placed in a room temperature environment (temperature 20-25°C, relative humidity 30-45% RH), Sn whiskers appear 2-4 hours after polishing, and then grow rapidly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com