Micro heat pipe array board phase-change heat storage and release method and system

A phase change heat storage and micro heat pipe technology, applied in the field of high-efficiency phase change energy storage systems, can solve the problems of heating facilities occupying floor space, poor thermal conductivity of phase change materials, and unsatisfactory heat storage and release effects, etc. Heat transfer mode, stable performance, heat storage and fast heat extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

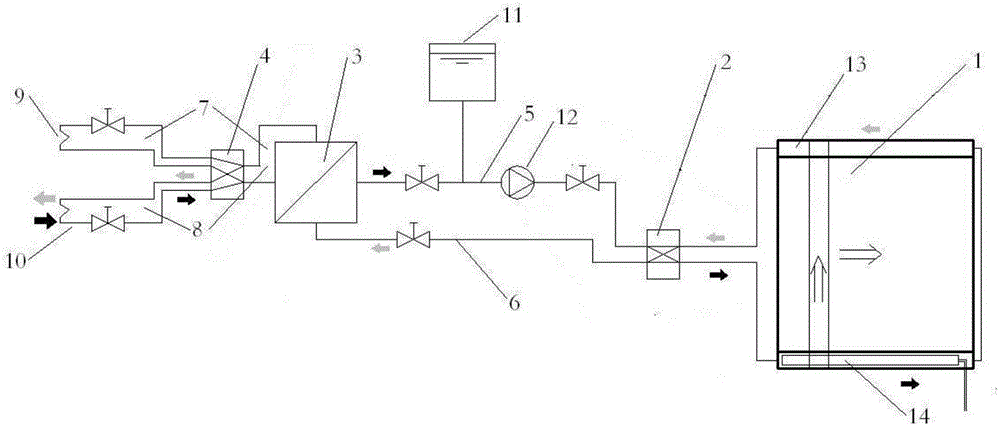

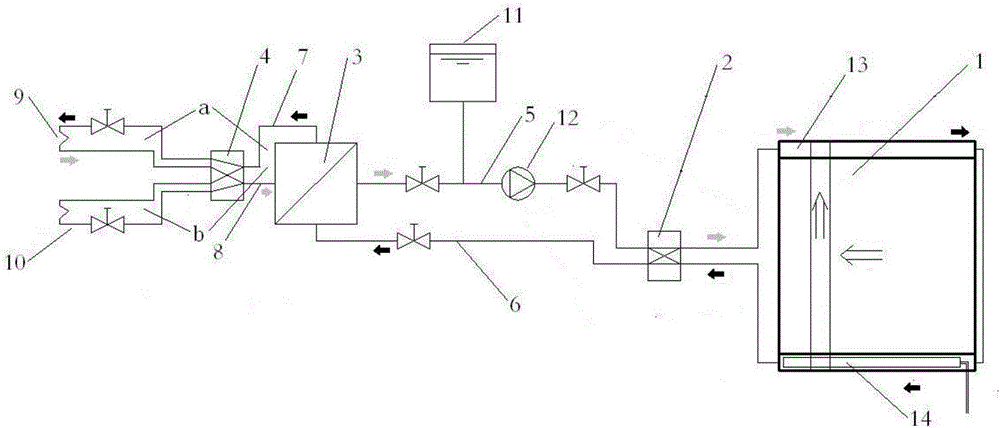

[0050] The heating end of this embodiment is a hot water heat exchange type. Whole by figure 1 and figure 2 As shown, it includes the heat accumulator 1 of the micro heat pipe array plate, the heat exchanger 3, and the pipeline connecting the user side 9, the heat source 10, the heat exchanger 3 and the heat accumulator 1, and the first four-way for switching the pipeline connection relationship The valve 2 and the second four-way valve 4 , the user side 9 and the heat source 10 exchange heat with the heat accumulator 1 through the heat exchanger 3 .

[0051] The heat accumulator 1 is a rectangular container of 1.1×1.6×0.4 as a whole, and the outer shell 16 is a rectangular container made of aluminum plate and polyurethane foam for heat preservation, and its interior is formed by a 10×9 array of heat storage units 15, such as image 3 , 4 shown. The heat storage unit 15 is designed based on the micro heat pipe array plate 17, a high-performance heat transfer material. Eac...

Embodiment 2

[0054] The heating end 14 of the present embodiment is electric heating and hot water mixing type, such as Figure 6 As shown, the micro heat pipe array plate 17 of the heating end 14 is wrapped with an electric heating belt 19. In the heat storage condition, the electric heating belt 19 and the heat carrier simultaneously provide heat to the heat storage section of the heat storage unit. Other structures and working principles are the same as in Embodiment 1.

Embodiment 3

[0056] The heating end 14 of the present embodiment is a single electric heating type, and only the micro heat pipe array plate 17 of the heating end 13 is embedded with a water exchange pipe, and the micro heat pipe array plate 17 of the heating end 14 has no heat exchange pipe. 17 wrapping electric heating belt 19, the structure of heating end 14 is as Figure 7 shown.

[0057] The piping structure of this embodiment is also different. Because of the single electric heating type, no heat source and heat source charging loop are required. When in the heat storage mode, the electric heating belt 19 at the heating end 14 is heated, and the working medium inside the micro heat pipe array plate 17 is heated and evaporated, and the heat is transferred from bottom to top in the form of steam, and the heat is conducted to the paraffin storage in the heat storage section. Stored in hot material. When in heating condition, such as Figure 8 As shown by the middle arrow, the micro-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com