Preparation method of polyester/para-position/meta-position aramid composite electric insulating paper

A technology of electrical insulation and composite paper, applied in plastic/resin/wax insulator, synthetic cellulose/non-cellulose material pulp/paper, special paper, etc., can solve the problem of poor insulation performance of paper, parchment, aramid paper machinery The problem of poor strength performance, etc., can achieve the effects of improved paper tightness, improved compressive strength, and regular and orderly arrangement of molecular chains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of polyester / para-position / meta-aramid composite electrical insulation paper of the present invention, specifically comprises the following steps:

[0031] Step 1, carry out pretreatment to PET chopped fiber, standby;

[0032] The pretreatment process of PET chopped fibers is: make PET chopped fibers at a molar concentration of 1.0×10 -3 mol / L~3×10 -3 mol / L, soak in sodium dodecylbenzenesulfonate solution at 40°C-60°C for 0.5h-1h, then wash with water for 3-5 times, and finally dry in a vacuum drying oven at 100°C-105°C until absolutely dry .

[0033] Step 2, pretreating PPTA chopped fibers;

[0034] The pretreatment process of PPTA chopped fibers is as follows: the PPTA chopped fibers are mixed at a molar concentration of 1.0×10 -3 mol / L~3×10 -3 mol / L, soak in sodium dodecylbenzenesulfonate solution at 40°C-60°C for 0.5h-1h, then wash with water for 3-5 times, and finally dry in a vacuum drying oven at 100°C-105°C until absolutely dry ...

Embodiment 1

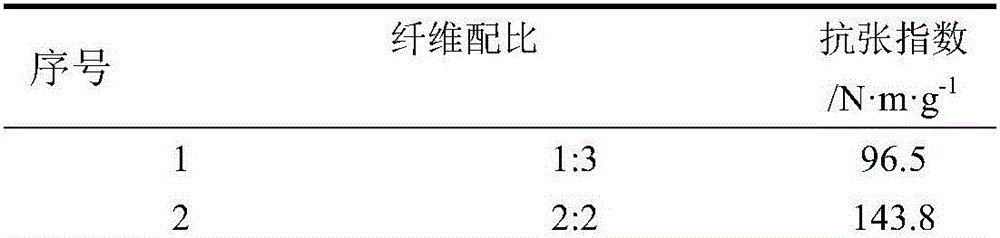

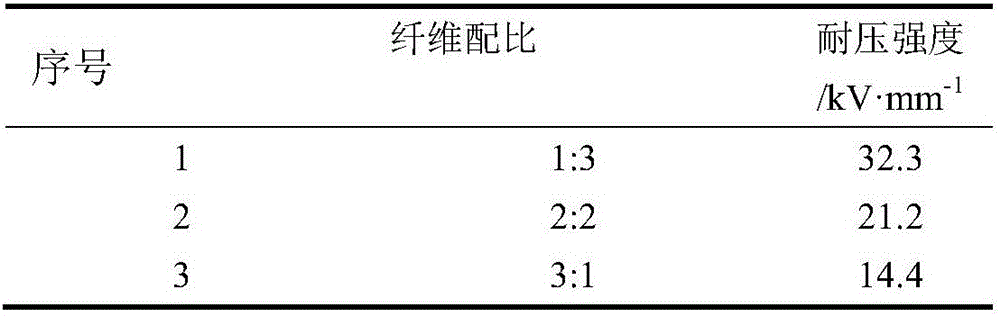

[0046] The PET chopped fibers are pretreated, the pretreatment process is: the PET chopped fibers at a molar concentration of 1.0×10 -3 mol / L, sodium dodecylbenzenesulfonate solution at a temperature of 40°C for 0.5h, then washed three times with water, and finally dried in a vacuum oven at 100°C to dryness for later use; PPTA chopped fibers were pre-treated Treatment, the pretreatment process is: the molar concentration of PPTA chopped fiber is 1.0×10 -3 mol / L, temperature of 40 ℃ sodium dodecylbenzene sulfonate solution soaked for 0.5h, then washed 3 times, and finally dried in a vacuum oven at 100 ℃ to absolute dryness; weighed 1.27g pretreated absolute Dry PET short-cut fibers and PPTA short-cut fibers are decomposed in a deflagging machine for 15000r, and the de-flaking concentration is controlled at 0.3% by mass (the total mass of absolute dry PET short-cut fibers and PPTA short-cut fibers is 1.27g), wherein the absolute-dry PET The mass ratio of chopped fiber to PPTA c...

Embodiment 2

[0048] Carry out pretreatment to PET short-cut fiber, pretreatment process is: the molar concentration of PET short-cut fiber is 3.0×10 -3 mol / L, soaked in sodium dodecylbenzenesulfonate solution at 60°C for 1 hour, then washed with water for 5 times, and finally dried in a vacuum drying oven at 105°C until completely dry, and set aside; PPTA chopped fibers were pretreated , the pretreatment process is: the molar concentration of PPTA chopped fibers is 3.0×10 -3 mol / L, soaked in sodium dodecylbenzenesulfonate solution at 60°C for 1 hour, then washed with water for 5 times, and finally dried in a vacuum oven at 105°C to absolute dryness; weighed 1.27g of pretreated absolute dryness PET short-cut fiber and PPTA short-cut fiber, 25000r in deflagging machine, deflaking concentration is controlled at 0.3% by mass (the total mass of dry PET short-cut fiber and PPTA short-cut fiber is 1.27g), wherein dry PET short-cut The mass ratio of cut fiber to PPTA chopped fiber is 3:1, then we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com