A kind of environment-friendly anti-migration agent and preparation method thereof

An anti-migration and environment-friendly technology, applied in dyeing, textile and papermaking, etc., can solve the problems of affecting the stability of dye liquor, easy deterioration of dye liquor, and dye migration, etc. Good swimming effect and the effect of improving cohesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

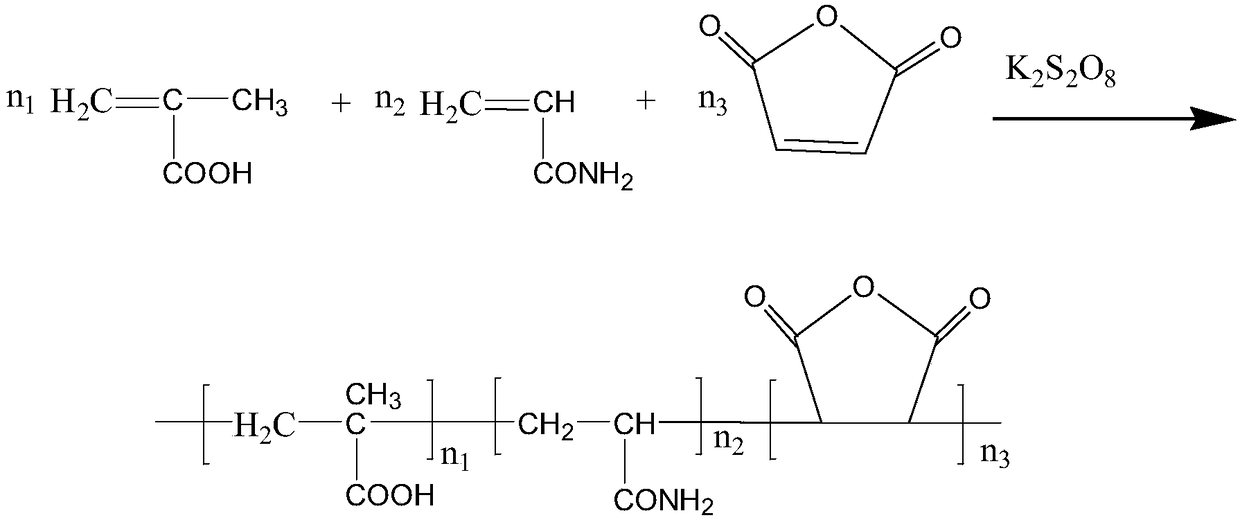

Method used

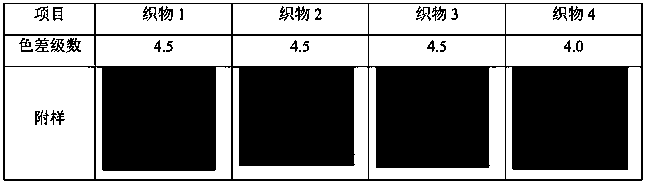

Image

Examples

Embodiment 1

[0031] 1. In the reaction kettle, add 60 parts of deionized water, 18 parts of methacrylic acid, 15 parts of acrylamide and 2 parts of maleic anhydride, stir and dissolve, and adjust the pH value to 6.5- 7.5, after being down to room temperature, add 3 parts of initiator potassium persulfate solution (the concentration of potassium persulfate solution is 10%) to obtain the reaction solution; get 2 / 3 of the prepared reaction solution and add it to another thermometer equipped with a thermometer. In the reaction kettle, heat it to 85-95°C under stirring, keep it warm for 30 minutes, then add the remaining reaction solution dropwise, and finish the dropwise addition in about 1 hour. Continue to keep warm at the same temperature for 2 hours. After the reaction, cool to room temperature. The obtained reaction product is component A, which has a viscous liquid appearance and a pH value of 6.5-7.5.

[0032] 2. Mix CMC and sodium alginate at a mass ratio of 2:8 to obtain component B; ...

Embodiment 2

[0035] 1. In the reaction kettle, add 64 parts of deionized water, 15 parts of methacrylic acid, 13 parts of acrylamide and 3 parts of maleic anhydride, stir and dissolve, and adjust the pH value to 6.5- 7.5, after being down to room temperature, add 4 parts of initiator potassium persulfate solution (the concentration of potassium persulfate solution is 10%) to obtain the reaction solution; get 2 / 3 of the prepared reaction solution and add it to another thermometer equipped with a thermometer. In the reaction kettle, heat it to 85-95°C under stirring, keep it warm for 30 minutes, then add the remaining reaction solution dropwise, and finish the dropwise addition in about 1 hour. Continue to keep warm at the same temperature for 2 hours. After the reaction, cool to room temperature. The obtained reaction product is component A, which has a viscous liquid appearance and a pH value of 6.5-7.5.

[0036] 2. Mix CMC and sodium alginate at a mass ratio of 2:8 to obtain component B; ...

Embodiment 3

[0039] 1. In the reaction kettle, add 58 parts of deionized water, 20 parts of methacrylic acid, 14 parts of acrylamide and 5 parts of maleic anhydride, stir to dissolve, and adjust the pH value to 6.5- 7.5, after being down to room temperature, add 5 parts of initiator potassium persulfate solution (the concentration of potassium persulfate solution is 10%) to obtain the reaction solution; get 2 / 3 of the prepared reaction solution and add it to another thermometer equipped with a thermometer. In the reaction kettle, heat it to 85-95°C under stirring, keep it warm for 30 minutes, then add the remaining reaction solution dropwise, and finish the dropwise addition in about 1 hour. Continue to keep warm at the same temperature for 2 hours. After the reaction, cool to room temperature. The obtained reaction product is component A, which has a viscous liquid appearance and a pH value of 6.5-7.5.

[0040] 2. Mix CMC and sodium alginate at a mass ratio of 2:8 to obtain component B; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com