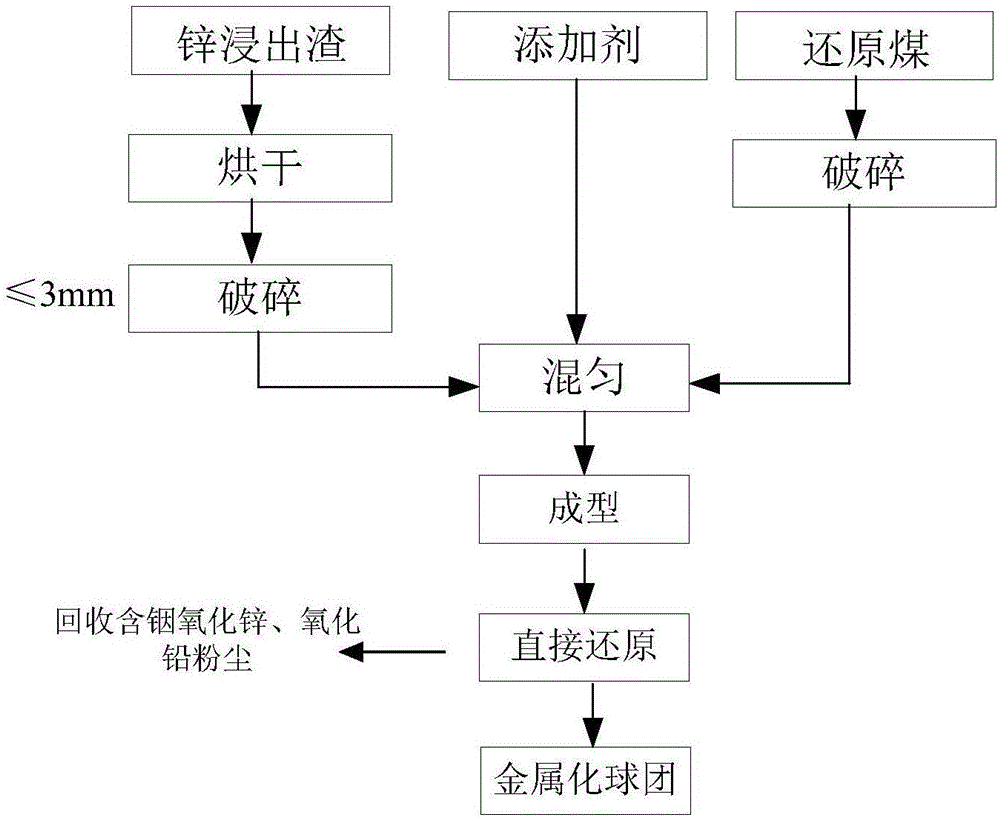

Direct reduction method and system of zinc leaching slag

A zinc leaching slag, direct technology, applied in the field of metallurgy, can solve the problems of large acid consumption, unrecoverable silver, large consumption of refractory materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Dry the zinc leaching slag. After drying, the zinc content in the slag is 4.34%, the lead content is 5.11%, the indium content is 380g / t, the silver content is 270g / t, and the iron content is 27%. After drying, it is broken to less than 3mm. The dosage of reduced coal is 27% of dry slag weight, 8% of diatomite and 2% of bentonite are added. (2) Mix the zinc slag, reduced coal, bentonite, and diatomite, add water and mix again, and press the pellets through the molding equipment. The drop strength of the pellets is measured for 6 times, which can basically meet the requirements for the strength of the rotary hearth furnace. (3) After forming, the pellets are dried until the water content is less than 4%, and sent into a direct reduction rotary hearth furnace for reduction roasting. The reduction temperature in the furnace is 1250°C, and the reduction time is 50 minutes. (4) In the metallized pellets obtained in step (3), the zinc content in the pellets is 0.23%, th...

Embodiment 2

[0051] (1) Dry the zinc leaching slag. After drying, the zinc content in the slag is 4.34%, the lead content is 5.11%, the indium content is 380g / t, the silver content is 270g / t, and the iron content is 27%. After drying, it is broken to less than 3mm. The dosage of reduced coal is 27% of dry slag weight, 5% of diatomite and 10% of bentonite are added. (2) Mix zinc slag, reduced coal, bentonite, and diatomite, add water and mix again, and press the ball through the molding equipment. The drop strength of the pellet is determined to be more than 20 times, and the pellet strength is high, which can fully meet the requirements of bottom rotation. Furnace into the furnace strength requirements. (3) After forming, the pellets are dried until the water content is less than 4%, and sent into a direct reduction rotary hearth furnace for reduction roasting. The reduction temperature in the furnace is 1300°C, and the reduction time is 42 minutes. (4) In the metallized pellets obtaine...

Embodiment 3

[0053] (1) Dry the zinc leaching slag. After drying, the zinc content in the slag is 4.34%, the lead content is 5.11%, the indium content is 380g / t, the silver content is 270g / t, and the iron content is 27%. After drying, it is broken to less than 3mm. The dosage of reduced coal is 27% of dry slag weight, 5% of diatomite and 10% of bentonite are added. (2) Mix the zinc slag, reduced coal, bentonite, and diatomite, add water and mix again, and press the ball through the molding equipment. The drop strength of the pellet is determined to be more than 20 times, and the pellet strength is high, which can completely meet the bottom rotation Furnace into the furnace strength requirements. (3) After forming, the pellets are dried until the water content is less than 4%, and sent into a direct reduction rotary hearth furnace for reduction roasting. The reduction temperature in the furnace is 1330°C, and the reduction time is 37 minutes. (4) In the metallized pellets obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com