Synthetic method of empagliflozin

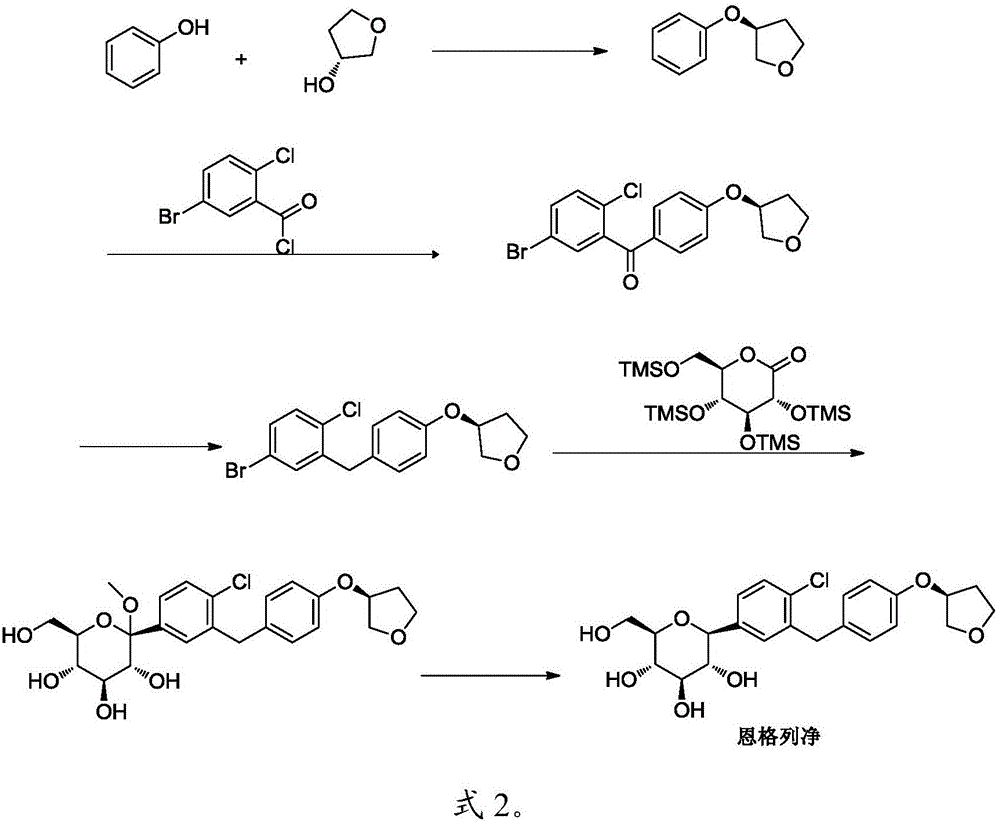

A synthetic method, the technology of empagliflozin, applied in the field of empagliflozin synthesis, can solve the problems of low total yield and long process route, and achieve the effect of short synthetic route, high total yield and favorable industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a kind of synthetic method of Empagliflozin, comprising the following steps:

[0039] A) Using 2,3,4,6-tetra-O-benzyl-D-glucopyranosic acid-1,5-lactone and p-chloroiodobenzene as raw materials, after reaction, the intermediate shown in formula II is obtained :

[0040]

[0041] B) Reduction eliminates the hydroxyl group on the anomeric carbon of the intermediate shown in the formula II to obtain the intermediate shown in the formula III:

[0042]

[0043] C) Using (S)-3-phenoxytetrahydrofuran and the intermediate shown in formula III and paraformaldehyde as raw materials, after reaction, the intermediate shown in formula IV is obtained:

[0044]

[0045] D) removing the benzyl protecting group on the intermediate represented by the formula IV to obtain Empagliflozin.

[0046] The invention discloses a new method for preparing empagliflozin, which has a short synthesis route and a high total yield, which is beneficial to industrializatio...

Embodiment 1

[0081] The preparation of embodiment 1 (S)-3-phenoxytetrahydrofuran

[0082]

[0083] Into a 500mL three-necked flask, 300mL of DMF, 30g (319mmol) of phenol, 77.2g (319mmoL) of (R)-3-tetrahydrofuryl p-toluenesulfonate, and 104g (319mmoL) of cesium carbonate were successively added, and the reaction was carried out at room temperature for 20 hours. After the reaction, add 1N dilute hydrochloric acid to the system to adjust the pH value to 7-8, extract with ethyl acetate, combine the organic phases, wash the organic phase with saturated brine, dry with anhydrous magnesium sulfate, and concentrate the obtained filtrate under reduced pressure , a brown crude product was obtained. 300 mL of isopropanol was added to the obtained crude product for recrystallization to obtain 45.0 g of off-white solid product, that is, (S)-3-phenoxytetrahydrofuran with a purity of 99% and a yield of 87%.

[0084] The structure of the product was confirmed by mass spectrometry (MS) and nuclear magn...

Embodiment 2

[0085] The preparation of embodiment 2 intermediate II

[0086]

[0087] Add p-chloroiodobenzene (12.8g, 54mmoL) and tetrahydrofuran-toluene mixed solvent (1:2 volume ratio, 120mL in total) into a 500mL three-necked flask. Cool to -78°C, add 2.2 mol / L n-butyllithium n-hexane solution (36 mL, 80 mmoL) dropwise, and stir for 30 min to obtain a mixed solution. Then, the mixture was slowly added dropwise to 2,3,4,6-tetra-O-benzyl-D-glucopyranosic acid-1,5-lactone (43.0 g, 80 mmol) in toluene (120 mL), stirred for 2 h, then added saturated citric acid solution to adjust the pH to 7.5, warmed up to room temperature, and continued to stir for 5 h. After the reaction, the organic phase of the system was separated, the aqueous phase was extracted with ethyl acetate (80mL×3 times), the organic phases were combined, washed with saturated brine (120mL), dried with anhydrous sodium sulfate and filtered, and the resulting filtrate was reduced to The solvent was evaporated under pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com