Method for preparing modified biomass charcoal for passivating lead and cadmium in soil and modified biomass charcoal

A technology of biochar and biomass raw materials, which is applied in the direction of chemical instruments and methods, soil conditioning materials, fertilizer mixtures, etc., can solve the problems of destroying the structure of biochar, large amount of biochar, and easily corroded equipment, etc., and achieve improvement Environmental benefits, high passivation strength, and the effect of reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

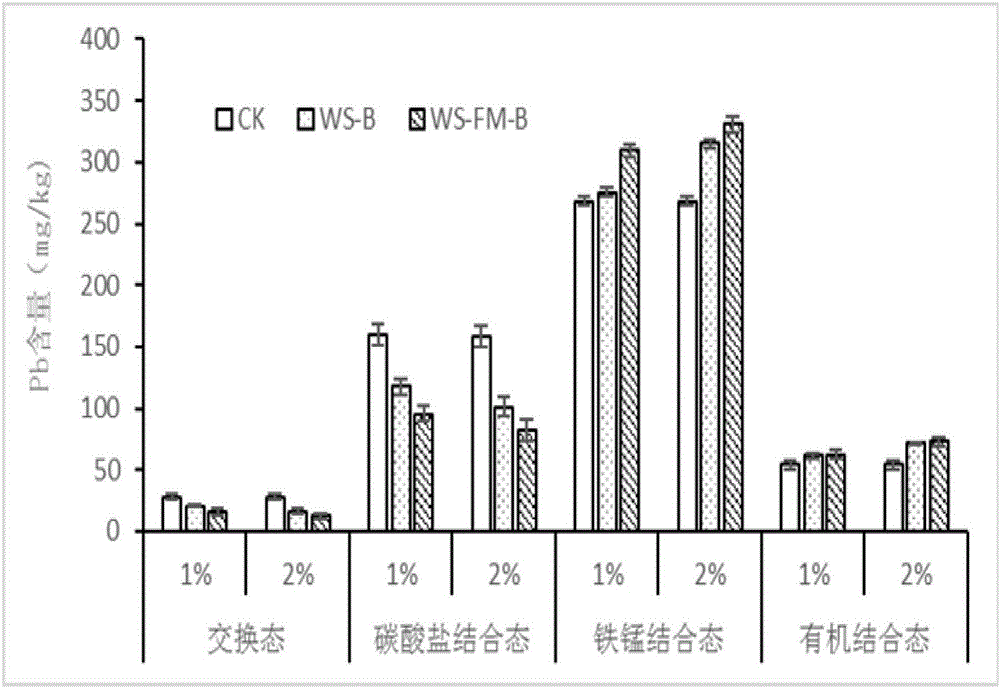

Embodiment 1

[0030] 1. Preparation of modified biomass charcoal, see the process figure 1 : After collecting and air-drying the wheat stalks, crush them and pass through a 20-mesh sieve for use. Take FeSO according to the ratio of the amount of material 3: 1 4 ·7H 2 O and KMnO 4 Dissolve in water to form solution one and solution two respectively. After the solution one and the solution two are evenly mixed, the pH is adjusted to 7 with a potassium hydroxide solution with a concentration of 1 mol / L, and stirring is continued until the reaction is fully obtained to obtain an iron manganese oxide suspension. Add the crushed and sieved wheat straw to the iron-manganese oxide suspension (the mass ratio of wheat straw to iron-manganese oxide is 20:1), stir well, soak for 24 hours, and put it in an oven for drying at 105°C 6h to obtain wheat straw loaded with iron and manganese oxides. Put the iron-manganese oxide-loaded wheat straw into a stainless steel tank with a diameter of 10cm and a height...

Embodiment 2

[0037] After the wheat straw is collected and air-dried, it is crushed and passed through a 60-mesh sieve for use. Take FeSO according to the ratio of the amount of material 2:1 4 ·7H 2 O and KMnO 4 Dissolve in water to form solution one and solution two respectively. After the solution one and the solution two are evenly mixed, the pH is adjusted to 7 with a potassium hydroxide solution with a concentration of 1 mol / L, and stirring is continued until the reaction is fully obtained to obtain an iron manganese oxide suspension. Add the crushed and sieved wheat straw to the iron-manganese oxide suspension (the mass ratio of wheat straw to iron-manganese oxide is 30:1), stir well, soak for 24 hours, and put it in an oven for drying at 90°C 7h to obtain wheat straw loaded with iron and manganese oxides. Put the iron-manganese oxide-loaded wheat straw into a stainless steel tank with a diameter of 10cm and a height of 15cm, compact it, and then put it in a muffle furnace under oxyge...

Embodiment 3

[0039] After the wheat straw is collected and air-dried, it is crushed and passed through a 100-mesh sieve for use. Take FeSO according to the ratio of the amount of material 5:1 4 ·7H 2 O and KMnO 4 Dissolve in water to form solution one and solution two respectively. After the solution one and the solution two are evenly mixed, the pH is adjusted to 7 with a potassium hydroxide solution with a concentration of 1 mol / L, and stirring is continued until the reaction is fully obtained to obtain an iron manganese oxide suspension. Add the crushed and sieved wheat straw to the iron-manganese oxide suspension (the mass ratio of wheat straw to iron-manganese oxide is 40:1), stir well, soak for 24 hours, and put it in an oven at 120°C for drying 5h to obtain wheat straw loaded with iron and manganese oxides. Put the iron-manganese oxide-loaded wheat straw into a stainless steel tank with a diameter of 10 cm and a height of 15 cm, compact it, and then put it in a muffle furnace under o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com