Nanometer silicon carbide fiber-modified C/C sealing material and preparation method thereof

A technology of nano-silicon carbide and sealing materials, applied in the field of nano-silicon carbide fiber modified C/C sealing materials and its preparation, to achieve the effect of ensuring stable friction and enhancing friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

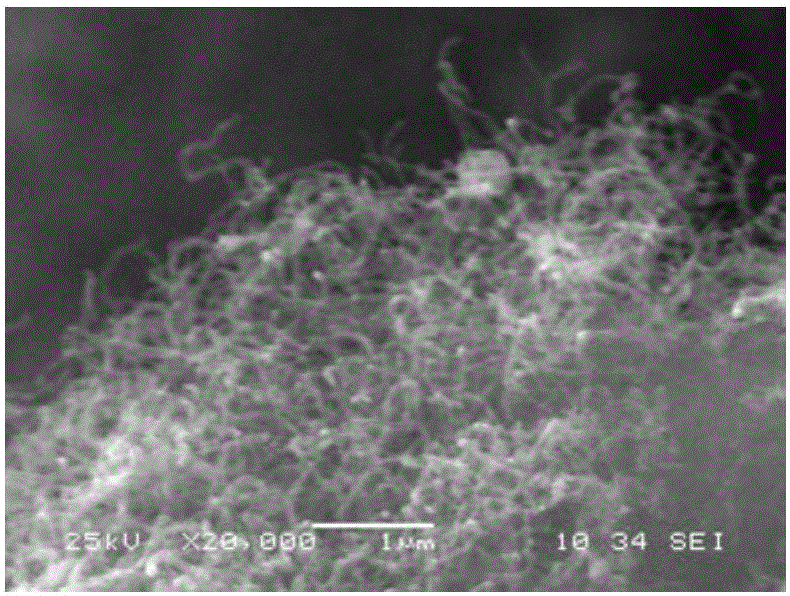

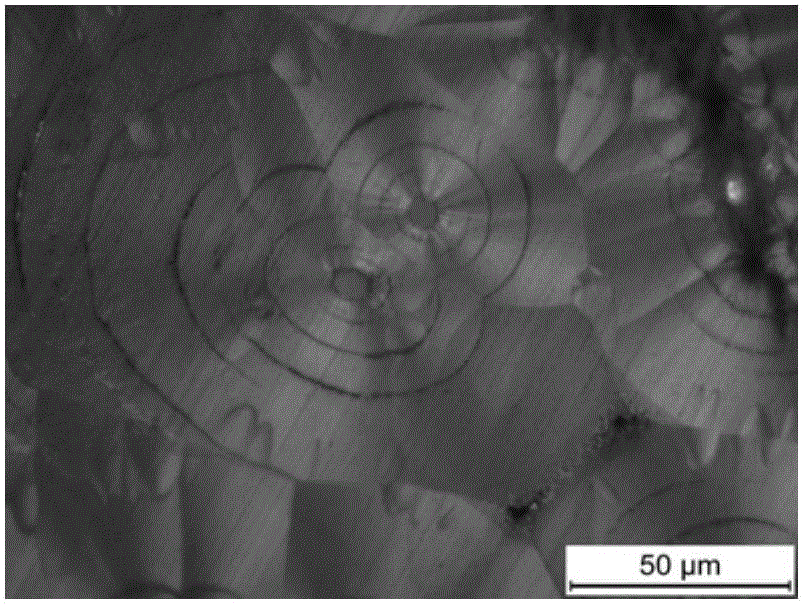

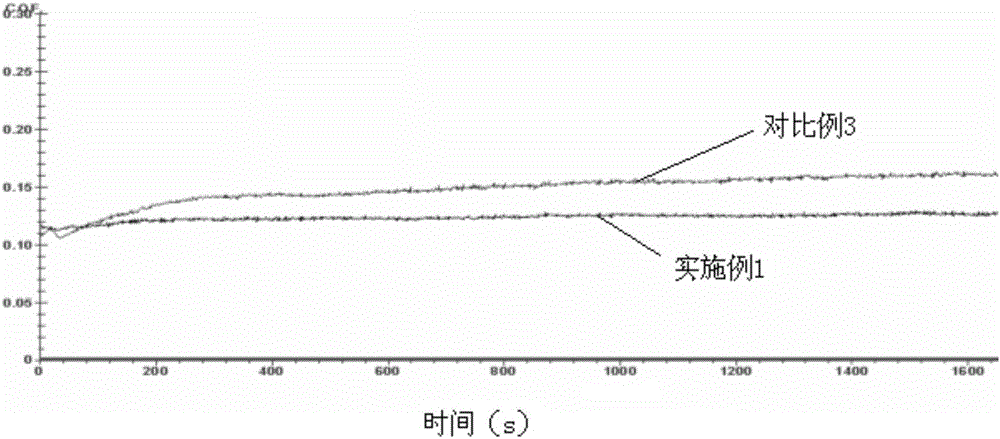

Embodiment 1

[0038] In terms of mass percentage, the components of the designed sealing material are:

[0039] Carbon fiber preform + deposited carbon 92.7%;

[0040] Nano Ni 0.3%;

[0041] Nano silicon carbide fiber 7%;

[0042] Wherein the mass ratio of carbon fiber prefabricated body to deposited carbon is 10; 7

[0043] (1) Ultrasonic vibration of the 3D carbon fiber preform in acetone solution for half an hour, soaking for 24 hours, the mass ratio of carbon fiber and acetone solution is 1:12, and then washed repeatedly with deionized water for 8 times and placed in a drying box drying for use;

[0044] (2) Soak the preform obtained in step (1) in 0.2% nickel nitrate solution for 5 hours, take it out and place it in a thermostat at 100° C. for 7 hours and dry it for 7 hours. Then put the preform into the tube furnace, under N 2 Heating to 500°C for calcination in the atmosphere and keeping it for 2 hours to remove NO 3 roots; and then heated to 580 ° C, H 2reduction to obtain ca...

Embodiment 2

[0050] In terms of mass percentage, the components of the designed sealing material are:

[0051] Carbon fiber preform + deposited carbon 94.8%;

[0052] Nano Ni 0.2%;

[0053] Nano silicon carbide fiber 5%;

[0054] Wherein the mass ratio of carbon fiber prefabricated body to deposited carbon is 10; 6

[0055] (1) Ultrasonic vibration of the 3D carbon fiber preform in acetone solution for half an hour, soaking for 24 hours, the mass ratio of carbon fiber and acetone solution is 1:12, and then washed repeatedly with deionized water for 8 times and placed in a drying box drying for use;

[0056] (2) Soak the preform obtained in step (1) in 0.2% nickel nitrate solution for 5 hours, take it out and place it in a thermostat at 100° C. for 7 hours and dry it for 7 hours. Then put the preform into the tube furnace, under N 2 Heating to 500°C for calcination in the atmosphere and keeping it for 2 hours to remove NO 3 roots; and then heated to 580 ° C, H 2 reduction to obtain c...

Embodiment 3

[0062] In terms of mass percentage, the components of the designed sealing material are:

[0063] Carbon fiber preform + deposited carbon 89.6%;

[0064] Nano Ni 0.4%;

[0065] Nano silicon carbide fiber 10%;

[0066] Wherein the mass ratio of carbon fiber prefabricated body to deposited carbon is 10; 6

[0067] (1) Ultrasonic vibration of the 3D carbon fiber preform in acetone solution for half an hour, soaking for 24 hours, the mass ratio of carbon fiber and acetone solution is 1:12, and then washed repeatedly with deionized water for 8 times and placed in a drying box drying for use;

[0068] (2) Soak the preform obtained in step (1) in 0.4% nickel nitrate solution for 5 hours, take it out and place it in a thermostat at 100° C. for 7 hours and dry it. Then put the preform into the tube furnace, under N 2 Heating to 500°C for calcination in the atmosphere and keeping it for 2 hours to remove NO 3 roots; and then heated to 580 ° C, H 2 reduction to obtain catalyst nic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com