A method of manufacturing a volute with a composite lining

A composite material and manufacturing method technology, applied in liquid fuel engines, components of pumping devices for elastic fluids, non-variable-capacity pumps, etc., can solve the problem that the size of the cavity between the impeller and the volute is difficult to precisely control, Affect the reliability of pumps, fans and compressors, reduce the efficiency of pumps, fans and compressors, etc., to achieve the effect of improving operating efficiency and reliability, avoiding deformation, and reducing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

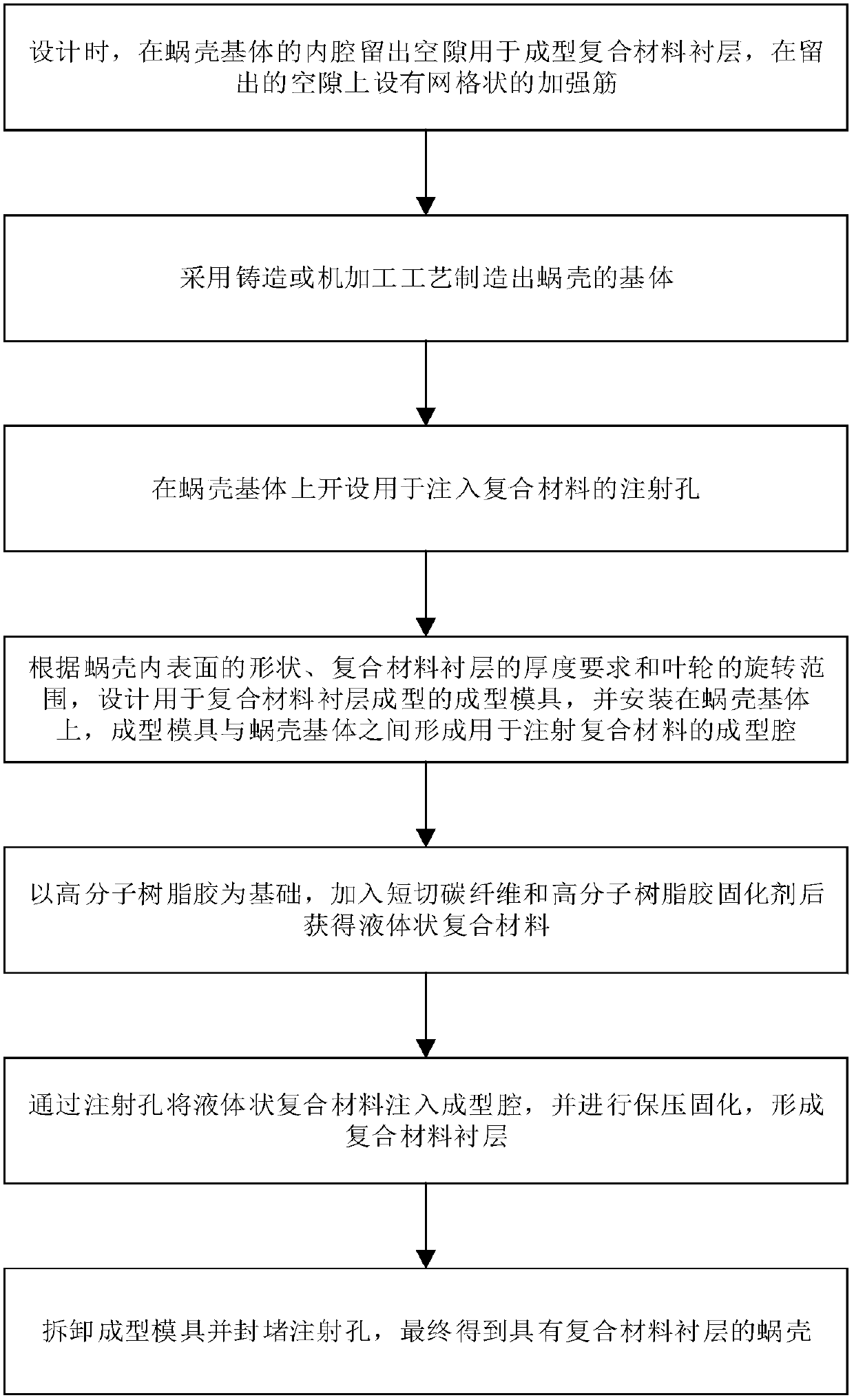

[0038] The invention also discloses a method for manufacturing a volute structure with a composite material liner 120. The volute with a composite material liner 120 manufactured by this method is used in pumps, fans and compressors, which can significantly reduce internal Gas or liquid flow resistance, improving the efficiency and reliability of pumps, fans and compressors, such as figure 1 As shown, the specific steps of the method are as follows:

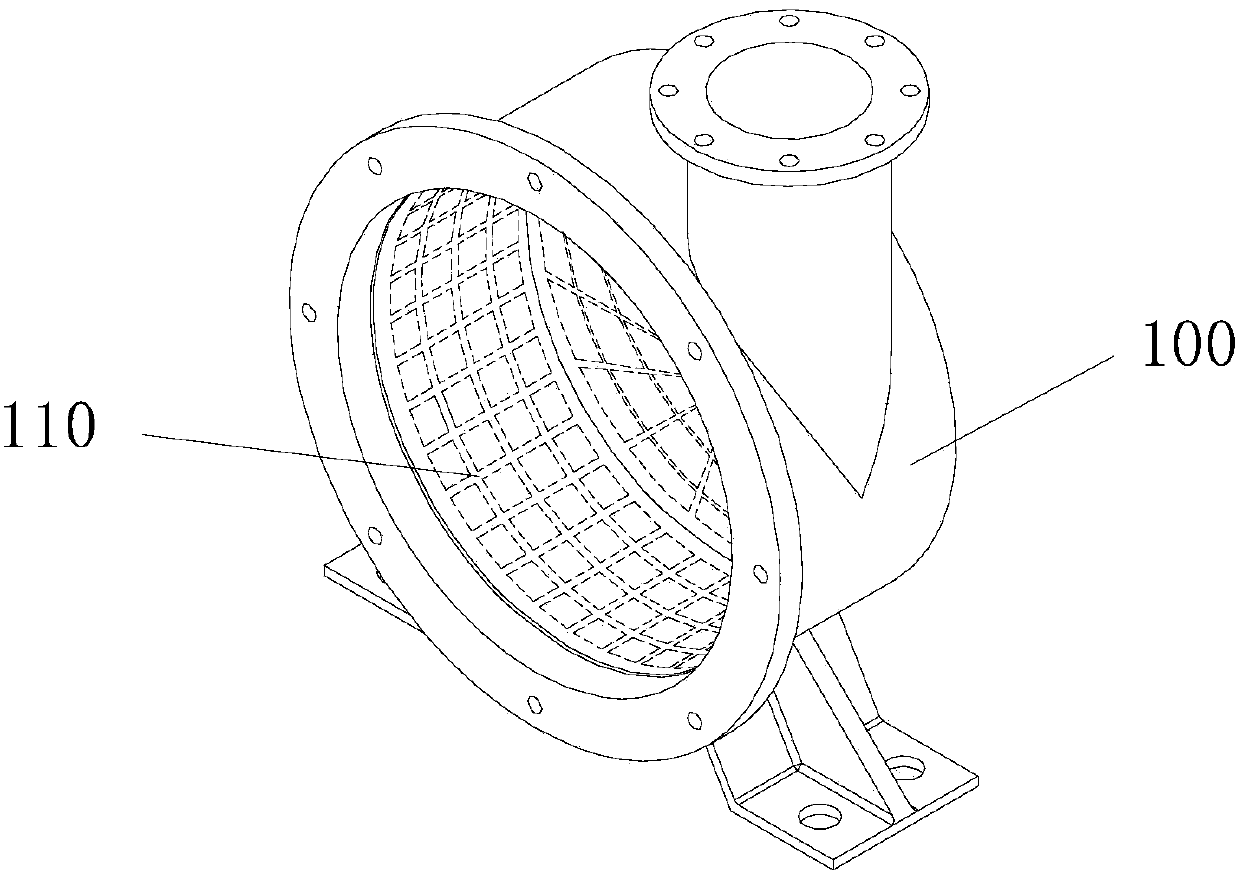

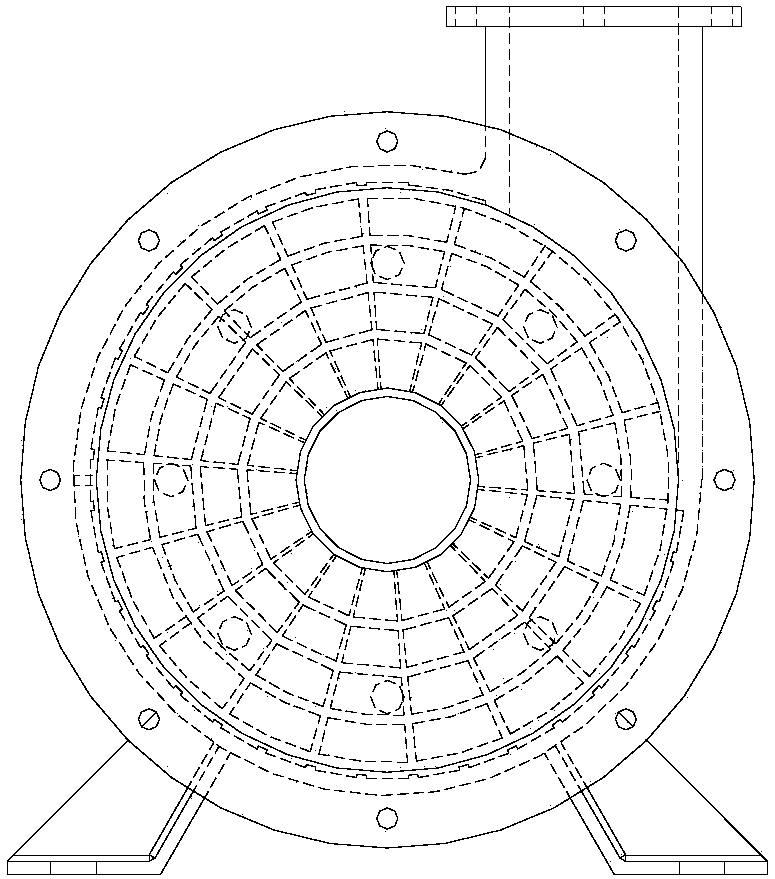

[0039] Step S1: Combine Figure 2 to Figure 5 As shown, according to the shape and structure requirements of the volute, the shell of the volute base 100 is designed, and a gap of 2-4 mm is designed at the part where the cavity is formed between the shell of the volute and the impeller, and the gap is used to form a composite lining 120; in addition, a grid-shaped reinforcing rib 110 with a thickness of 1-2 mm is designed at the same time, and the shape and size of other parts of the volute remain unchanged.

[0040]Step S2: Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com