Manufacturing method of cutting and grinding resin wheel

A technology of resin grinding wheel and manufacturing method, which is applied in the direction of grinding device, manufacturing tool, bonded grinding wheel, etc., can solve the problems of easy carbonization of non-metal, waste of loss and resource, negative impact of workpiece, etc., to achieve the benefit of reprocessing and saving Energy, burn reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

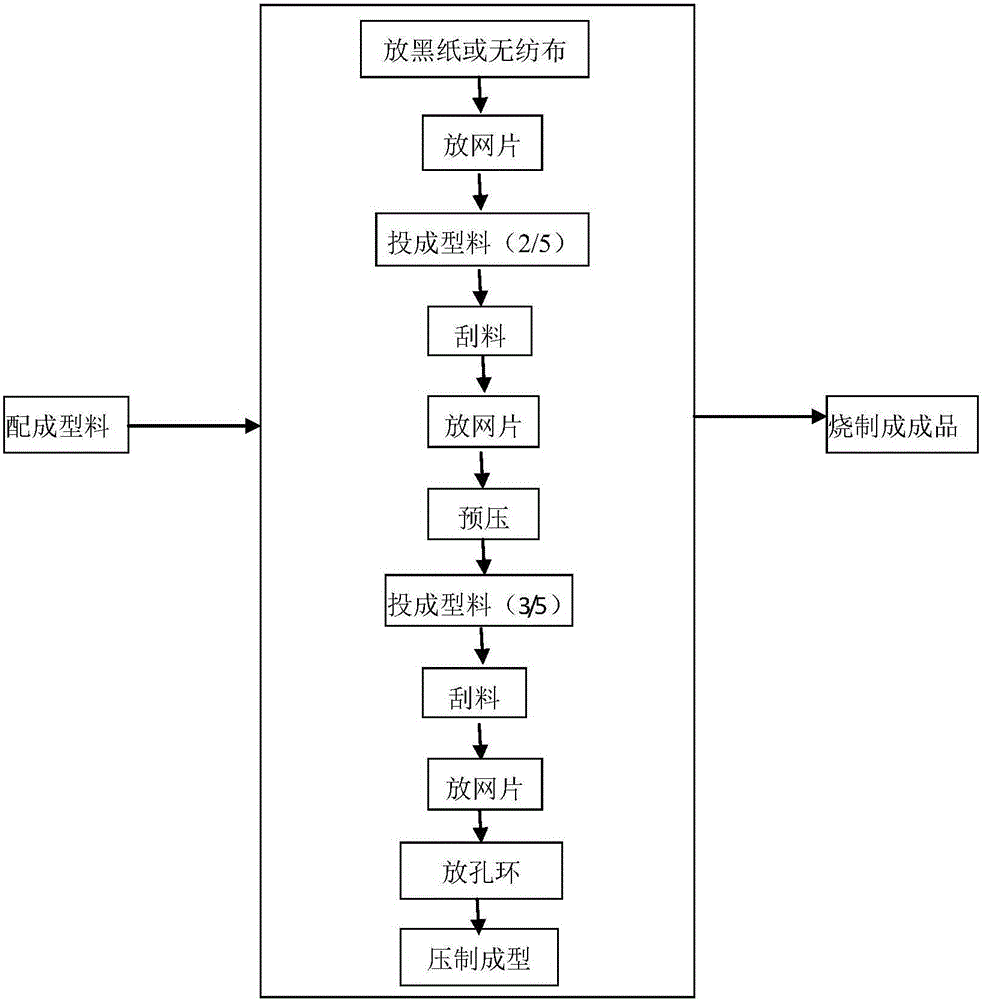

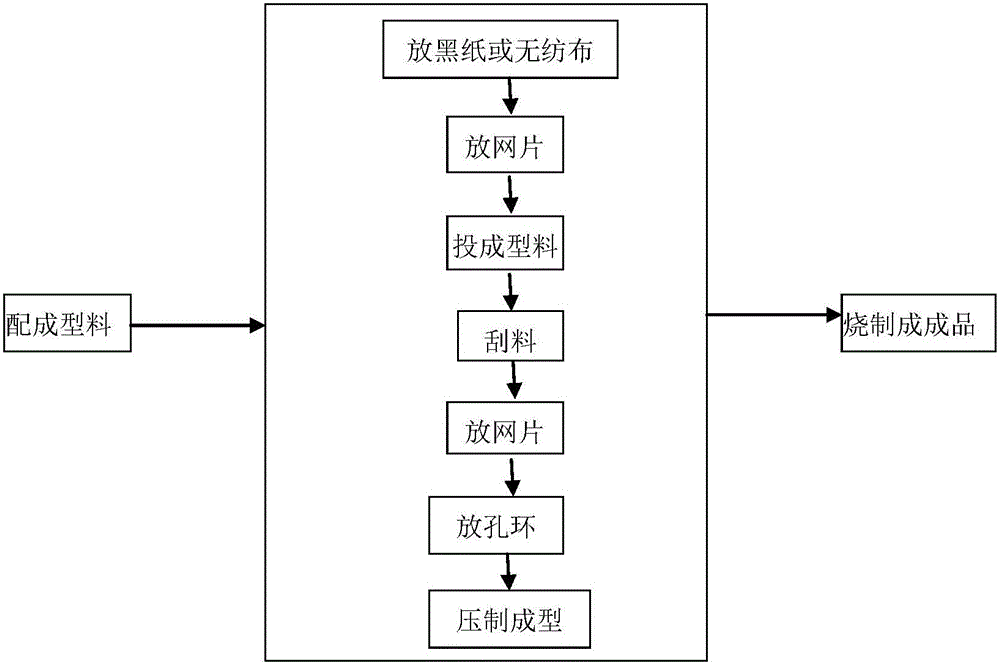

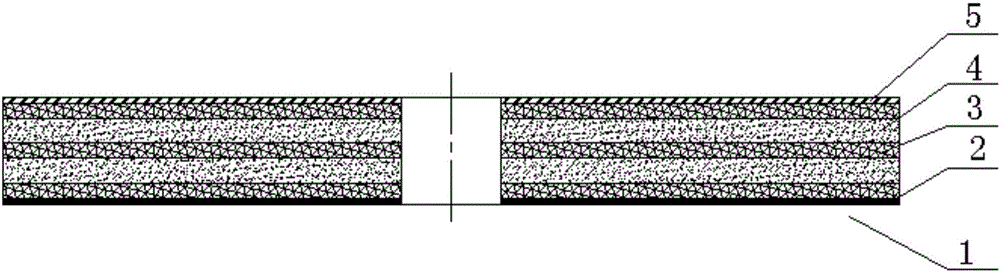

[0033] The manufacturing method of the cutting and grinding resin grinding wheel of the present invention comprises the step of preparing molding material, the step of forming the semi-finished resin blank of the resin grinding wheel and the step of firing the finished product.

[0034] Step 1. Prepare molding materials:

[0035] When making molding materials, use high-adhesive phenolic resin and fine-grained abrasives (60#, 80#, 100#) to mix according to a certain ratio to make molding materials with moderate dry humidity, and park them for 4-8 hours for later use.

[0036] Among them, the raw materials and weight proportions used in the preparation of molding materials are: 30-50 parts of single crystal corundum, 50-70 parts of coated corundum, 20-25 parts of phenolic resin powder, 9-15 parts of phenolic resin liquid, 8-12 parts of cryolite,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com