Low-pressure casting method, cooling control process and exhaust system of large impeller

A low-pressure casting and impeller technology, applied in the field of precision casting, can solve the problems that the same control method as low-pressure casting cannot be used, the structure is complex, and the diameter of large thin-walled impellers is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

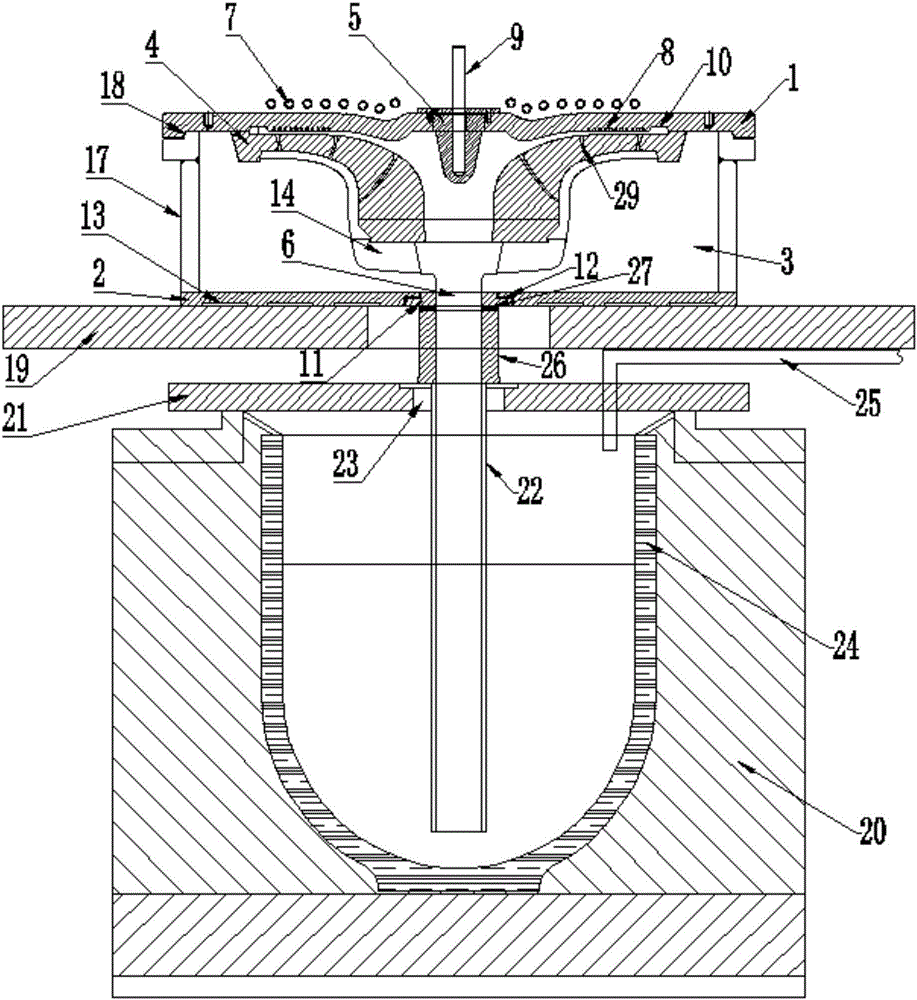

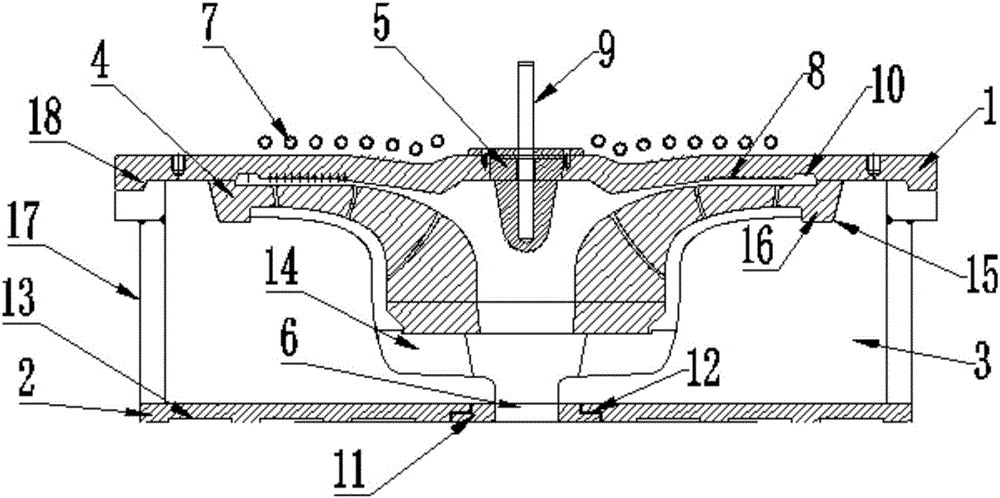

[0115] Such as figure 1 As shown, the impeller low-pressure casting system includes an impeller casting mold and a low-pressure casting device. The low-pressure casting device includes a casting platform 19 supporting the mould. The casting platform 19 is fixed on the ground, and upper and lower metal molds are placed on it. The center of the casting platform 19 It is hollow, and the middle heater 26 passes through it. The lower part of the casting platform 19 is provided with a heating device 20, and the top of the heating device 20 is provided with a cover plate 21. The heating device 20 has a built-in crucible 24 for heating the crucible and the aluminum inside. The heating device 20 may be in direct contact with the crucible 24, or may be separated by an air layer or a heat transfer layer. The heating device can be a heating mantle or the like.

[0116] A riser pipe 22 is inserted inside the crucible 24, and an air inlet pipe 25 is provided on the cover plate 21 to provi...

Embodiment 2

[0131] In this embodiment, the molding element is a sand mold; the core is a gypsum core, and the core can also be made of other materials; the casting material is aluminum.

[0132] A method for low-pressure casting of a large impeller, comprising the following steps:

[0133] Step 1: Make sand molds with sand molds;

[0134] Step 2: Make a gypsum core using a gypsum mold;

[0135] Step 3: Dry the gypsum core in the dryer for 8-20 hours, put the sand mold in the dryer for 2-4 hours; turn on the gas heating device to preheat the upper mold for 2-4 hours;

[0136] Step 4: Put the aluminum ingot into the crucible, heat it through the heating device, and melt the aluminum ingot. When the molten aluminum reaches the set temperature (700-740°C), sprinkle the slagging agent into the molten aluminum, and use a special colander to remove the slag; turn on the argon gas, and degas and remove the slag from the molten aluminum;

[0137] Step 5: Assemble the upper metal mold, plaster c...

Embodiment 3

[0183] In this embodiment, the molding element in Embodiment 2 is replaced by a sand mold to a plaster mold; the core is a gypsum core; the casting material is aluminum.

[0184] A method for low-pressure casting of a large impeller, comprising the following steps:

[0185] Step 1: Make plaster type;

[0186] Step 2: Make a gypsum core using a gypsum mold;

[0187] Step 3: Put the gypsum core in the dryer for 8-20 hours, put the gypsum mold in the dryer for 2-4 hours; turn on the gas heating device to preheat the upper mold for 2-4 hours;

[0188] Step 4: Put the aluminum ingot into the crucible, heat it through the heating device, and melt the aluminum ingot. When the molten aluminum reaches the set temperature (700-740°C), sprinkle the slagging agent into the molten aluminum, and use a special colander to remove the slag; turn on the argon gas, and degas and remove the slag from the molten aluminum;

[0189] Step 5: Assemble the upper metal mold, gypsum core, gypsum mold,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com