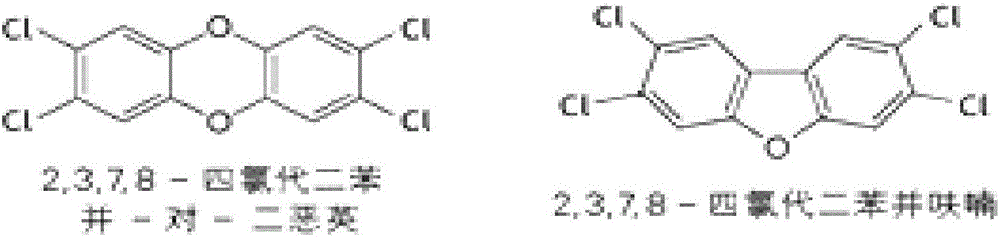

Preparation method and application of catalyst for removing dioxin from flue gas

A dioxin and catalyst technology, applied in the field of denitrification catalyst preparation, can solve the problems of increasing operating costs, etc., and achieve the effect of improving low-temperature activity, high mechanical strength, and superior low-temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Purchase commercially available metatitanic acid as a raw material, beat with deionized water, wash and filter, and remove unwashed SO 4 , so that SO 4 Controlled at 3-4% (with TiO 2 count);

[0033] (2) Take 1777.8g of metatitanic acid (TiO 2 content of about 45% (W)) add an appropriate amount of deionized water for beating, and add 3% (in the form of V) to the beating 2 o 5 38.6g of ammonium metavanadate) (use 5% oxalic acid solution to dissolve ammonium metavanadate under heating), after the metavanadate oxalic acid solution and metatitanic acid are fully mixed, then add 8mol of ammonia water dropwise to adjust the pH of the solution to 9.0-9.2, then filtered, washed with water, dried and pulverized for later use;

[0034] Get the above-mentioned metatitanic acid mixture loaded with vanadium, add high-viscosity attapulgite 133.3g (solid content is 90%), add hole expansion, lubricant: 30g of turmeric powder and molding binder: hydroxypropyl methyl Base cellu...

Embodiment 2

[0040] (1) Purchase commercially available metatitanic acid as a raw material, beat with deionized water, wash and filter, and remove unwashed SO 4 , so that SO 4 Controlled at 3-4% (with TiO 2 count);

[0041] (2) Take 1777.8 g of metatitanic acid after washing and add 6% (in V 2 o 5 77.2g of ammonium metavanadate, 3% (in terms of WO 3 In terms of) ammonium metatungstate 32.3g and 1% (as Nb 2 o 5 47.3g of niobium oxalate), and finally add 111g of high-viscosity attapulgite and an appropriate amount of deionized water for kneading, so that the active components are fully mixed, and then add hole expansion, lubricant: hydroxypropyl methylcellulose Plain 40g, continue kneading, and then extrude into a 50×50×100mm honeycomb titanium carrier on a special mold (honeycomb small hole 3×3mm);

[0042] (3) Drying and activation process conditions of the honeycomb titanium carrier loaded with active components: According to the indication and actual measurement of the differentia...

Embodiment 3

[0046] (1) Purchase commercially available metatitanic acid as a raw material, beat with deionized water, wash and filter, and remove unwashed SO 4 , so that SO 4 Controlled at 3-4% (with TiO 2 count);

[0047] (2) Take 1777.8g of metatitanic acid (TiO 2 content of about 45% (W)) add an appropriate amount of deionized water for beating, and add 7% (in the form of V) to the beating 2 o 5 90.1 g of ammonium metavanadate) (use 5% oxalic acid solution to dissolve ammonium metavanadate under heating), after the metavanadate oxalic acid solution and metatitanic acid are fully mixed, then add 8 mol of ammonia water dropwise to adjust the pH of the solution to 9.0-9.2, then filtered, washed with water, dried and pulverized for later use;

[0048] Get the above-mentioned metatitanic acid mixture loaded with vanadium, add high-viscosity attapulgite 111g, add 3% (as Nb 2 o 5 Total) 141.8g of niobium oxalate, adding hole expansion, lubricant: 30g of safflower powder and forming bin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com