Two-dimensional material-based quantum dot film for saturable absorber, preparation method thereof and application of quantum dot film to ultrafast laser

A technology of saturable absorption and two-dimensional materials, which is applied in the field of ultrafast pulsed lasers, can solve the problems of low light absorption rate, achieve simple preparation methods, meet application requirements, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

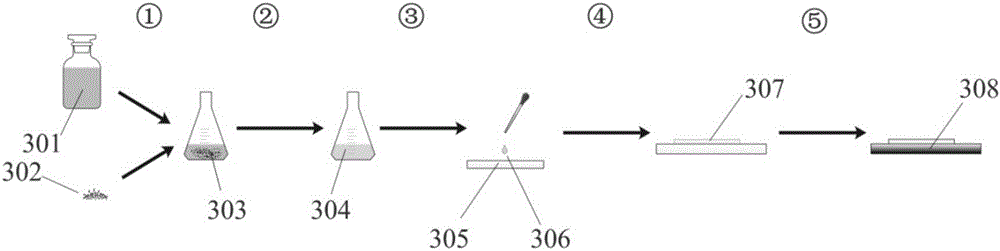

[0047] The second aspect of the present invention provides a method for preparing a quantum dot film based on a two-dimensional material for a saturable absorber, comprising the following steps:

[0048] A quantum dot solution based on two-dimensional materials is provided, wherein the quantum dots in the quantum dot solution based on two-dimensional materials are at least one of graphene quantum dots, topological insulator quantum dots, transition metal sulfide quantum dots and black phosphorus quantum dots, The size of quantum dots is below 100nm;

[0049] After ultrasonic dispersion, the quantum dot solution is dropped or coated on the substrate, and dried at 70-100° C. under vacuum conditions to form a two-dimensional material-based quantum dot film on the substrate.

[0050] In the embodiment of the present invention, the quantum dot solution is mixed with the polymer organic compound, and after ultrasonic dispersion, a mixed solution is obtained; the polymer organic comp...

Embodiment 1

[0088] A method for preparing a quantum dot film based on a two-dimensional material, comprising the following steps:

[0089] Provide black phosphorus quantum dot solution, mix 20mL black phosphorus quantum dot solution and 2mg polyvinyl alcohol, and ultrasonically disperse at a frequency of 50Hz to obtain a mixed solution; drop the mixed solution on the copper foil, and dry it at 70°C under vacuum , forming a black phosphorus quantum dot film on copper foil.

[0090] Copper foil with FeCl 3 Dissolved, and then, use the fiber tip to stick the floating FeCl 3 The quantum dot film on the solution, so that the quantum dot film is transferred from the copper foil to the end face of the optical fiber head.

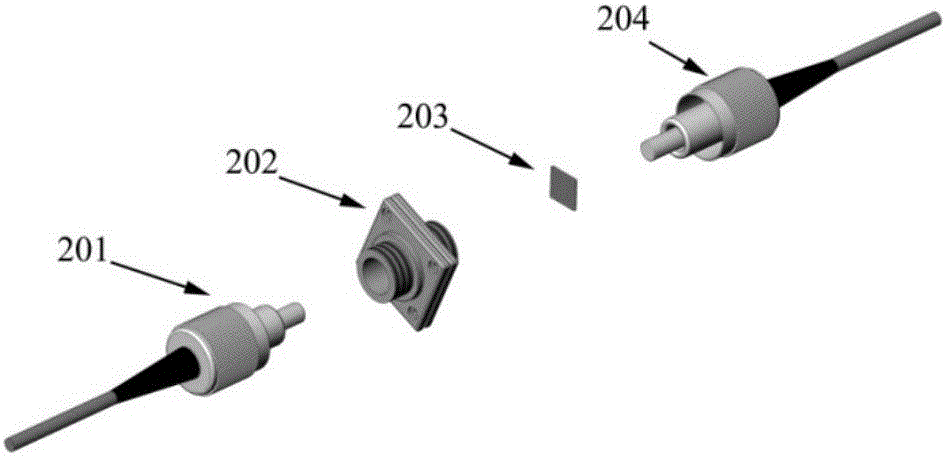

[0091] A saturable absorber, the saturable absorber includes an optical fiber connector, an optical fiber adapter, a black phosphorus quantum dot film and another optical fiber connector, wherein the optical fiber end surface of the optical fiber connector is bonded with a b...

Embodiment 2

[0096] A method for preparing a quantum dot film based on a two-dimensional material, comprising the following steps:

[0097] Provide a graphene quantum dot solution, mix 20mL graphene quantum dot solution and 2mg polymethyl methacrylate, and ultrasonically disperse at a frequency of 50Hz to obtain a mixed solution; drop the mixed solution on the copper foil, and store it at 100°C under vacuum After drying, a black phosphorus quantum dot film is formed on the copper foil.

[0098] Copper foil with FeCl 3 Dissolved, and then, use the fiber tip to stick the floating FeCl 3 The quantum dot film on the solution, so that the quantum dot film is transferred from the copper foil to the end face of the optical fiber head.

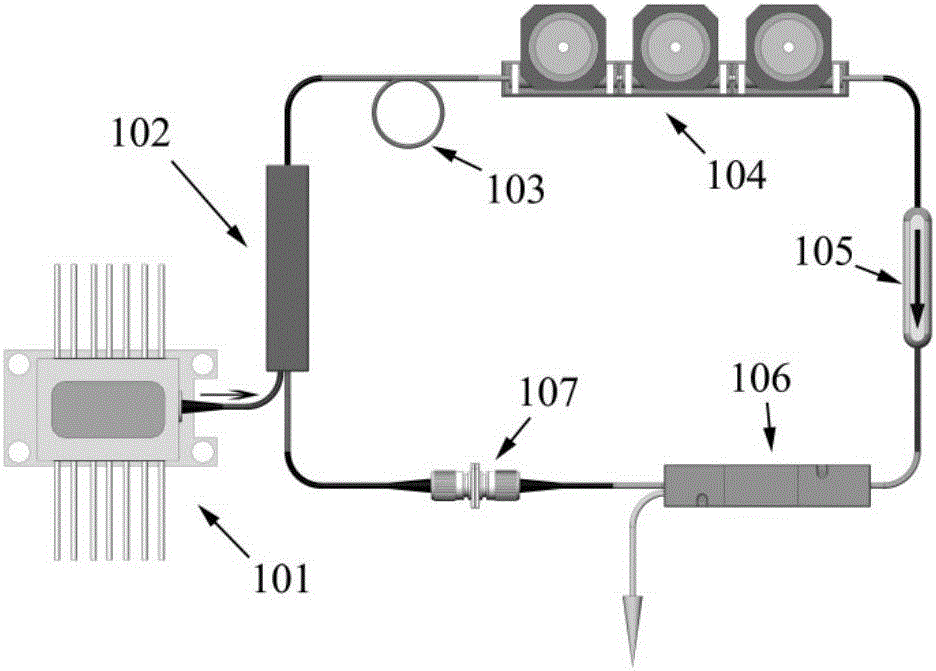

[0099] An all-fiber laser includes a pump source, a wavelength division multiplexer, an erbium-doped gain fiber, a polarization controller, a polarization-independent isolator, a fiber coupler and the above-mentioned saturable absorber.

[0100] In this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com