Plate grid alloy for positive plate of lead-acid storage battery

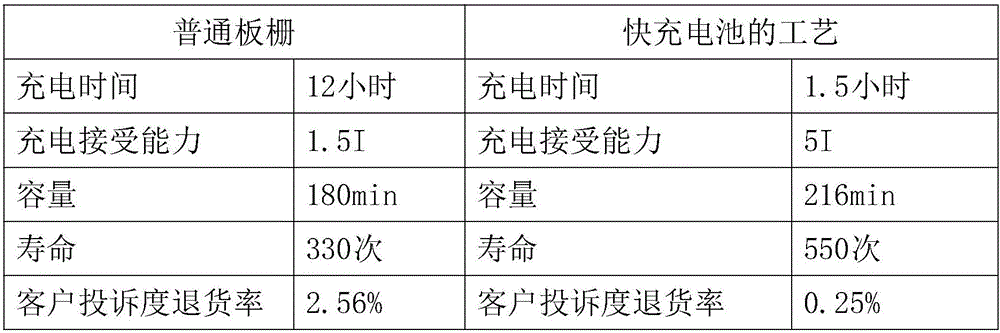

A lead-acid battery, positive plate technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of high energy consumption, cannot achieve environmental protection and energy saving, and achieve low energy consumption, prolong service life, and delay linearity. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

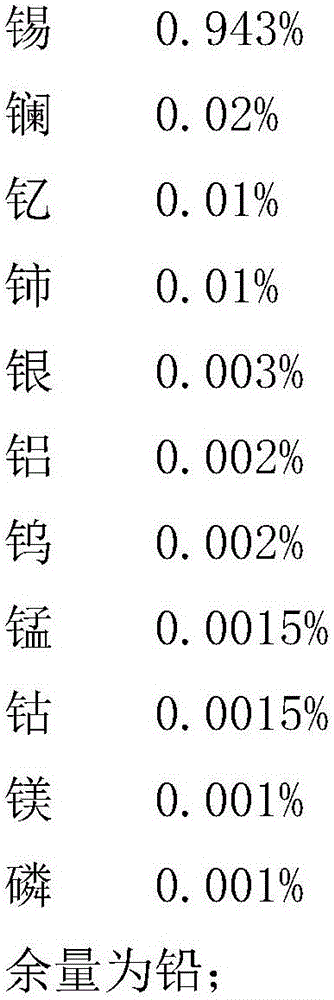

[0018] A grid alloy for the positive plate of a lead-acid storage battery, consisting of the following components by weight percentage:

[0019] Tin 0.943%, lanthanum 0.02%, yttrium 0.01%, cerium 0.01%, silver 0.003%, aluminum 0.002%, tungsten 0.002%, manganese 0.0015%, cobalt 0.0015%, magnesium 0.001%, phosphorus 0.001%, the rest is lead;

[0020] Its preparation method is as follows:

[0021] (1) First heat tin to 750°C, then slowly add lanthanum, yttrium and cerium, stir while adding, continue to stir for 10 minutes after all the metals are melted, then cool down to 500°C, drain the liquid, and cast tin-lanthanum-yttrium-cerium alloy ingot;

[0022] (2) Heat the tin-lanthanum-yttrium-cerium alloy ingot to 400°C, then add silver, aluminum, tungsten, manganese, cobalt, magnesium and phosphorus, continue heating to 550°C, keep stirring for 20 minutes, and obtain the tin master alloy;

[0023] (3) Heat the electrolytic lead to 600°C, then add the tin master alloy and stir eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com