Quantum-dot light-emitting diode and preparation method therefor

A quantum dot light-emitting and diode technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of unbalanced carrier transport rate, unbalanced hole and electron, high electron injection rate, etc. , to achieve the effects of reducing assembly cost, good solubility, and increasing the chance of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

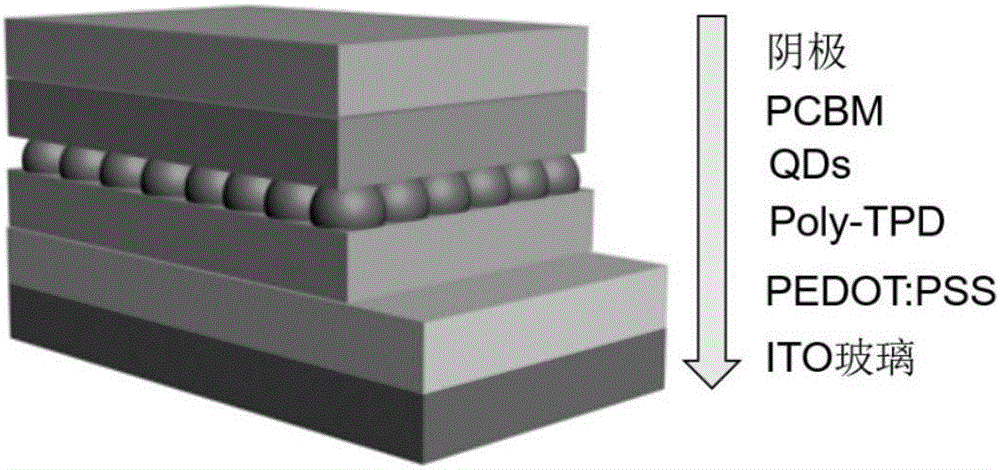

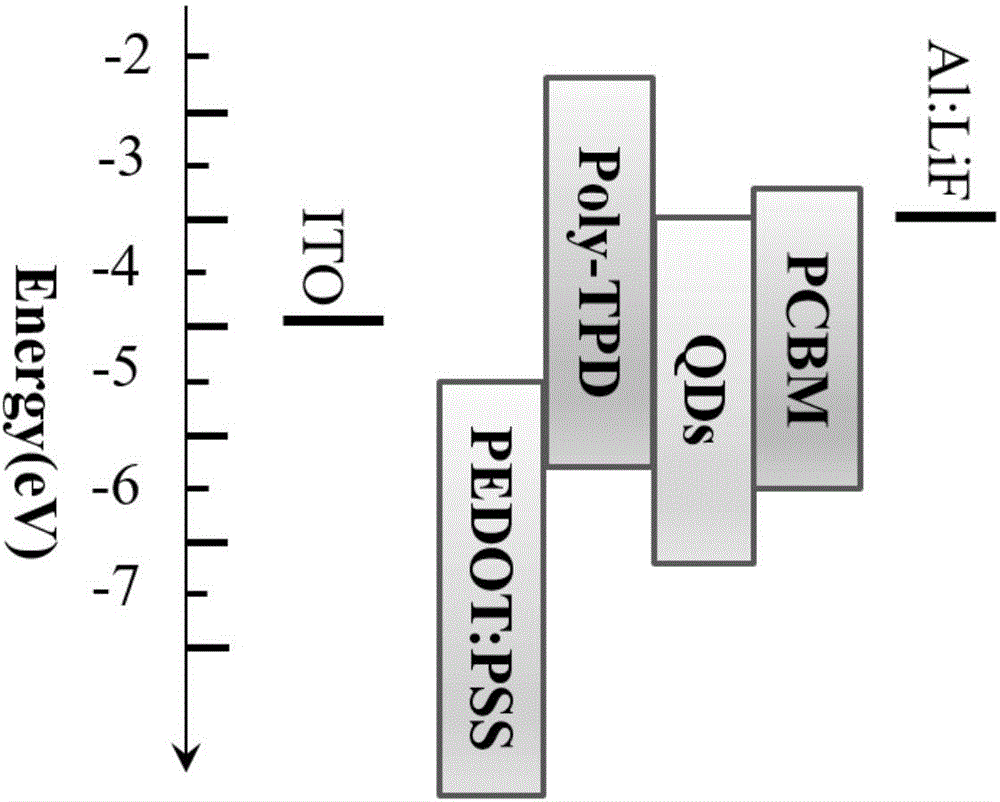

[0025] The ITO glass was placed in acetone, ethanol, and ultrapure water in sequence, and ultrasonically cleaned for 20 minutes, and dried for use after cleaning. Put the cleaned ITO glass in a UV-ozone analyzer for 10 minutes. Add isopropanol (PEDOT:PSS: isopropanol = 20:1) to PEDOT:PSS to adjust the viscosity, filter the prepared PEDOT:PSS isopropanol solution with a 0.45μm aqueous needle filter to remove Small amounts of slightly larger particulate matter in the solution. Next, QLEDs are prepared sequentially from anode to cathode (the energy level structure diagram is as figure 2 ), the preparation sequence is: spin-coating the filtered PEDOT:PSS solution on the ITO anode. The spin-coating process of PEDOT:PSS is: high-speed 4000rpm, time 30s, and then placed on a hot stage at 120°C for 15min annealing to form a void Hole injection layer film; deposit a poly-TPD chlorobenzene solution with a mass fraction of 1.5% on the PEDOT:PSS film. The spin coating process of Poly-TPD...

Embodiment 2

[0027] The ITO glass was placed in acetone, ethanol, and ultrapure water in sequence, and ultrasonically cleaned for 20 minutes, and dried for use after cleaning. Put the cleaned ITO glass in a UV-ozone analyzer for 10 minutes. Add isopropanol (PEDOT:PSS: isopropanol = 20:1) to PEDOT:PSS to adjust the viscosity, filter the prepared PEDOT:PSS isopropanol solution with a 0.45μm aqueous needle filter to remove Small amounts of slightly larger particulate matter in the solution. Next, QLEDs are prepared sequentially from anode to cathode (the energy level structure diagram is as Figure 4 ), the preparation sequence is: spin-coating the filtered PEDOT:PSS solution on the ITO anode, the spin-coating process of the PEDOT:PSS solution is: high-speed 4000rpm, time 30s, and then placed on a hot stage at 120°C and annealed for 15min to form Hole injection layer film; the configured toluene solution of PVK with a mass fraction of 2% is deposited on the PEDOT:PSS film, and then annealed ...

Embodiment 3

[0029] The ITO glass was placed in acetone, ethanol, and ultrapure water in sequence, and ultrasonically cleaned for 20 minutes, and dried for use after cleaning. Put the cleaned ITO glass in a UV-ozone analyzer for 10 minutes. Add isopropanol (PEDOT:PSS: isopropanol = 20:1) to PEDOT:PSS to adjust the viscosity, filter the prepared PEDOT:PSS isopropanol solution with a 0.45μm aqueous needle filter to remove Small amounts of slightly larger particulate matter in the solution. Next, QLEDs are prepared sequentially from anode to cathode (the energy level structure diagram is as figure 2 ), the preparation sequence is: spin-coating the filtered PEDOT:PSS solution on the ITO anode, the spin-coating process of the PEDOT:PSS solution is: high-speed 3000rpm, time 30s, and then put it on a hot stage at 120℃ for 15min annealing to form Hole injection layer thin film; the prepared poly-TPD chlorobenzene solution with a mass fraction of 2.5% is deposited on the PEDOT:PSS film. The spin c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com