A photographic manufacturing method for day and night reticle elements

A manufacturing method and component technology, applied in optical components, optics, instruments, etc., can solve the problems of low reticle accuracy, poor reticle quality, low processing efficiency, etc., and achieve high line width accuracy and position accuracy, The effect of good part consistency and high mass production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

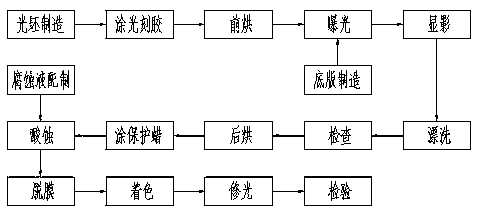

Method used

Image

Examples

Embodiment 1

[0033] φ50mm parts, requirements: line width 0.02mm±0.005mm, position accuracy 0.003mm, surface defect grade B=Ⅰ-20. Check the environmental parameters before starting work. The temperature is 24°C, the relative humidity is 53%, and the cleanliness is grade 6. Check the defect level of the photo blank surface B=Ⅰ-20, clamp the part to the centrifugal coating machine, control the speed at 3000r / min, evenly coat the BN303 negative photoresist on the photo blank surface, and dry it; inspection The accuracy of the photographic master plate meets the requirements. Contact the photographic master plate with the side coated with the adhesive layer downward, and expose it with an exposure machine for 150s; after development, rinsing, inspection, and drying, apply protective wax on the side of the part; Prepare glass corrosion solution with 25% hydrofluoric acid, 35% sulfuric acid and 40% phosphoric acid, immerse the parts in the glass corrosion solution for 15 seconds, rinse with clea...

Embodiment 2

[0035] φ20mm parts, requirements: line width 0.008mm±0.001mm, position accuracy 0.002mm, surface defect level B=Ⅰ-20. Check the environmental parameters before starting work. The temperature is 23°C, the relative humidity is 48%, and the cleanliness is grade 6. Check the defect level B= Ⅰ-20 on the surface of the photo blank, clamp the part to the centrifugal coating machine, control the speed at 4000r / min, evenly coat the BN303 negative photoresist on the surface of the photo blank, and dry it; inspection The accuracy of the photographic master plate meets the requirements. Contact the photographic master plate with the side coated with the adhesive layer downward, and use an exposure machine to expose the exposure time for 120s; after developing, rinsing, checking, and drying, apply protective wax on the side of the part; Prepare glass corrosion solution with 20% hydrofluoric acid, 40% sulfuric acid and 40% phosphoric acid, immerse the parts in the glass corrosion solution f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com