Rear lower side panel for car body integral side exterior plate

A side wall outer panel and car body technology, applied to vehicle parts, upper structure, upper structure sub-assembly, etc., can solve the problems of limited performance of body materials, complex external structure of side wall, and inability to fully realize the overall side wall design, etc. , to achieve the effect of good appearance and small weld gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

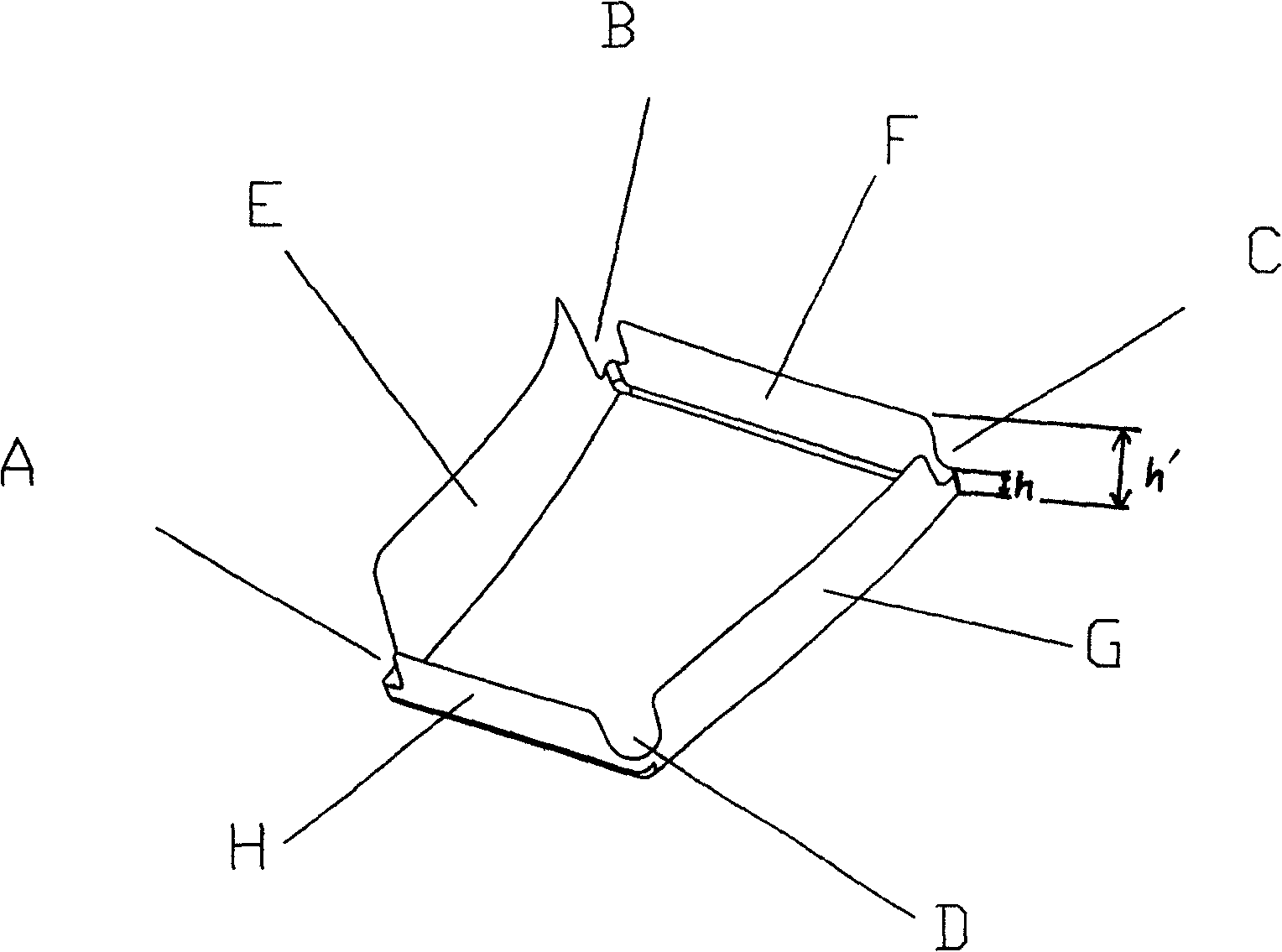

[0013] see figure 1 , the rear lower cover of the overall side wall outer panel of the car body is a box-shaped drawn part structure, and its four sides have four drawn flanges E, F, G, H formed by drawing. The corners of the cover surface are wrinkled, and the four corners A, B, C, and D of the box-shaped drawn part are designed to have openings, and the openings are still designed as partial tensile structures, and the tensile height h of the corners is much lower than that The height h` of a drawn flanging can ensure the integrity of the surface design of the cover.

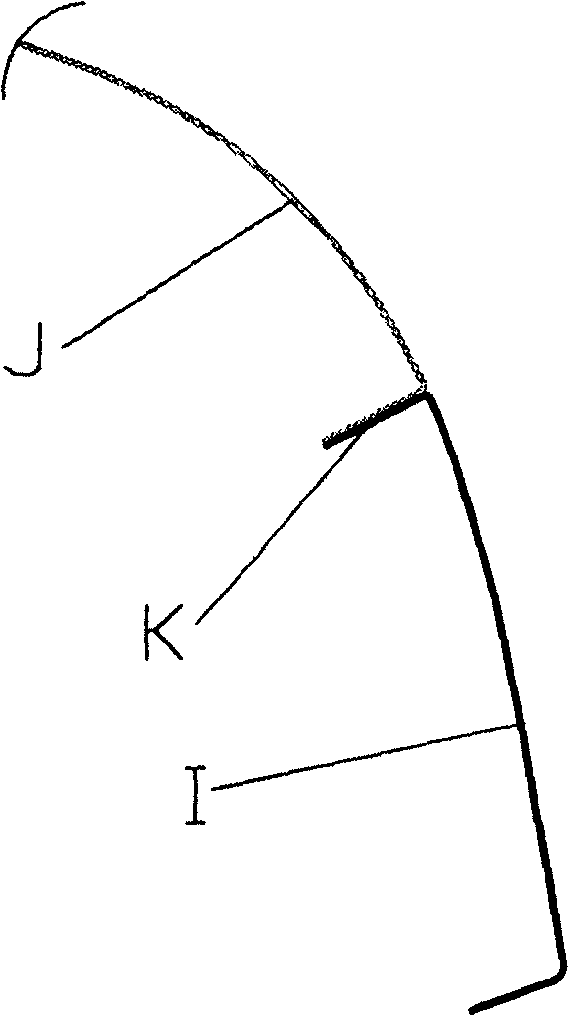

[0014] see figure 2 , the drawing flange F is overlapped with the outer panel J of the side wall, and connected by spot welding, K is the spot welding part, I is the rear lower cover plate of the side wall, and the other three drawing flanges E, G, H are respectively connected to the side wall All relevant parts at the rear of the enclosure are connected by spot welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com