Special-shaped refractory brick refractoriness under load and compressive creep test method

A technology for special-shaped refractory bricks and load softening, which is applied in the preparation of test samples, investigation phases/state changes, and the use of stable tension/pressure to test the strength of materials, etc. Change test performance and other issues to achieve good economic and social benefits, prolong service life, and ensure production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

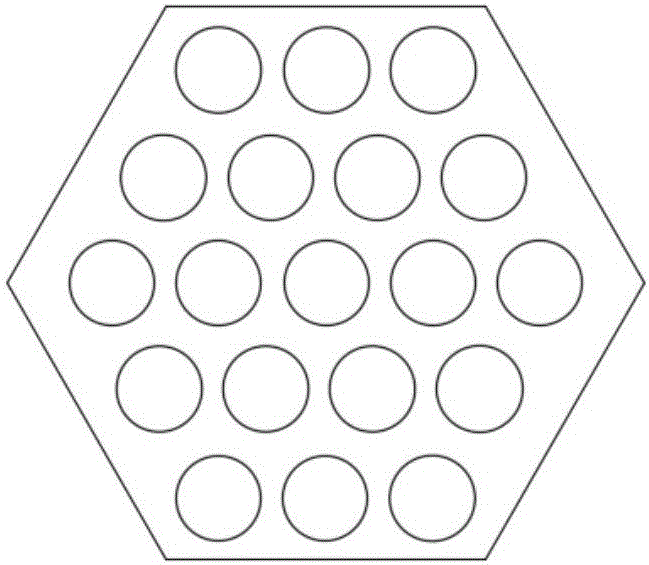

[0023] as attached figure 1 , 2 As shown, take the 19-hole checker brick for hot blast stove as an example.

[0024] (1) figure 1 It is a schematic plan view of a 19-hole checker brick. According to the size of the brick type, prepare a sample that is close to the size specified in the national standard or the metallurgical standard, and keep the original brick surface as much as possible. The two bottom surfaces should be parallel and the surface should be flat.

[0025] Standard sample for load softening temperature test, the metallurgical standard stipulates a cylinder with a diameter of 36±0.5mm and a height of 50±0.5mm, and the national standard is a cylinder with a diameter of 50±0.5mm, a height of 50±0.5mm, and a central through hole diameter of 12 to 13mm of cylinders. According to the actual size of the checker brick, select the national standard as a ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com