Hex screw and manufacturing method thereof

A hexagonal screw and external thread technology, which is applied in the direction of screws, mechanical equipment, threaded fasteners, etc., can solve the problem of easy slipping between the nut and the inner hexagonal wrench, poor wear resistance and corrosion resistance, and difficulty in turning the hexagonal screw. Convenience and other issues, to achieve the effect of speeding up the sintering reaction speed, clean and pollution-free interface, and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

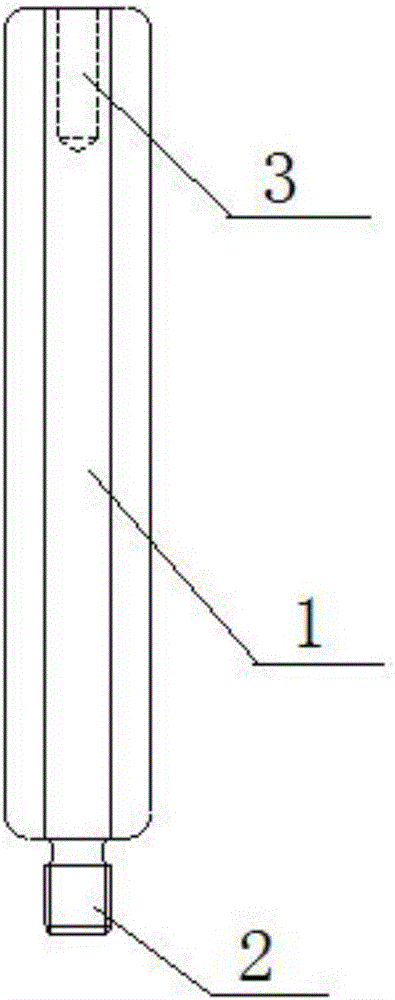

[0032] a kind of like figure 1 , figure 2 The shown hexagonal screw includes a main body and a connecting bolt arranged at one end of the main body, the other end of the main body is provided with a connecting hole, the connecting bolt has an external thread structure, the connecting hole has an internal thread structure, the connecting bolt, The connection holes are arranged coaxially with the main body in its extending direction. The hexagonal screws are made of alloy steel composite material, and the alloy steel composite material includes an alloy steel matrix and a ceramic layer clad on the surface of the alloy steel matrix by laser cladding. The alloy steel matrix is composed of the following components (by mass percentage): C: 0.40%, Si: 0.35%, Mn: 0.50%, Cr: 0.60%, Ni: 0.12%, Cu: 0.05%, Mo: 0.10% , Mg: 0.30%, Ti: 0.08%, W: 0.3%, V: 0.22%, RE: 0.12%, P≤0.018%, S≤0.015%, the balance is Fe and unavoidable impurity elements. The ceramic layer is SiC / Si 3 N 4 Composi...

Embodiment 2

[0034] The difference between this example and Example 1 is that the alloy steel matrix is composed of the following components (by mass percentage): C: 0.35%, Si: 0.40%, Mn: 0.40%, Cr: 0.70%, Ni: 0.08%, Cu: 0.06%, Mo: 0.08%, Mg: 0.35%, Ti: 0.05%, W: 0.4%, V: 0.12%, RE: 0.16%, P≤0.018%, S≤0.015%, balance Fe and inevitable impurity elements; the ceramic layer is SiC / Si 3 N 4 Composite ceramics, SiC / Si 3 N 4 The composite ceramic includes the following components in mass percentage: 3.0% C, 26% N, 5% Cu, 5% Fe, 5% Y, and the balance is Si. Others are the same as in Example 1 and will not be repeated here.

Embodiment 3

[0036] The difference between this example and Example 1 is that the alloy steel matrix is composed of the following components (by mass percentage): C: 0.45%, Si: 0.30%, Mn: 0.60%, Cr: 0.55%, Ni: 0.15%, Cu: 0.04%, Mo: 0.12%, Mg: 0.25%, Ti: 0.12%, W: 0.25%, V: 0.25%, RE: 0.08%, P≤0.018%, S≤0.015%, balance Fe and inevitable impurity elements; the ceramic layer is SiC / Si 3 N 4 Composite ceramics, SiC / Si 3 N 4 The composite ceramic includes the following components in mass percentage: 2.0% C, 27% N, 2.5% Cu, 6% Fe, 4% Y, and the balance is Si. Others are the same as in Example 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com