Anticorrosive, anti-explosion and environment-friendly type liquid ring vacuum unit

A liquid ring vacuum and liquid ring vacuum pump technology, which is applied to liquid fuel engines, mechanical equipment, machines/engines, etc., can solve the problems of damage to the pump body and impeller of liquid ring pumps, affect the service life of equipment, and pollute the medium, and achieve Protecting the environment, reducing equipment failure rate and safety accident risk, the effect of large society and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

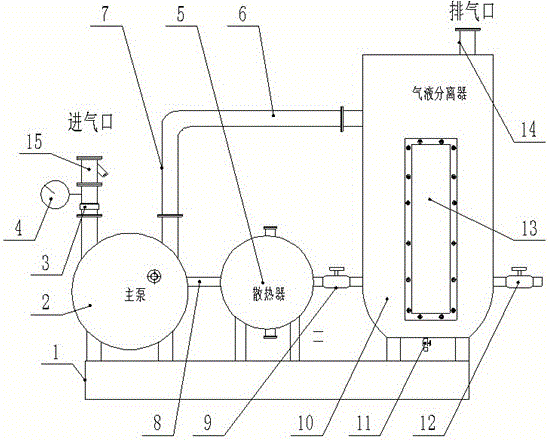

[0015] In the present invention, a Y-shaped pipeline filter (15) is first installed at the exhaust port of the container, and the Y-shaped pipeline filter (15) is connected to a pipeline, and an upper point contact explosion-proof vacuum pressure gauge (4) is installed on the pipeline, and then the The check valve (3) is connected in series with the suction port of the main pump liquid ring vacuum pump (2). The main pump liquid ring vacuum pump (2) is equipped with an explosion-proof motor. The liquid separator (10) is connected, the gas and other substances inhaled by the unit and the working fluid of the liquid ring pump (2) of the main pump enter the gas-liquid separator (10) through the pipeline, and the gas-liquid separation is carried out in the gas-liquid separator (10). Separation, the liquid remains in the gas-liquid separator, the gas is discharged in an environmentally friendly manner, the liquid enters the radiator (10) through the pipe for heat exchange and cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com