Remote control method of height adjustment of coal shearer based on virtual reality

A remote control and virtual reality technology, which is applied in the direction of earthwork drilling and cutting machinery, etc., can solve problems such as improper control, the shearer will cut to the roof and floor or faults, safety accidents, failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

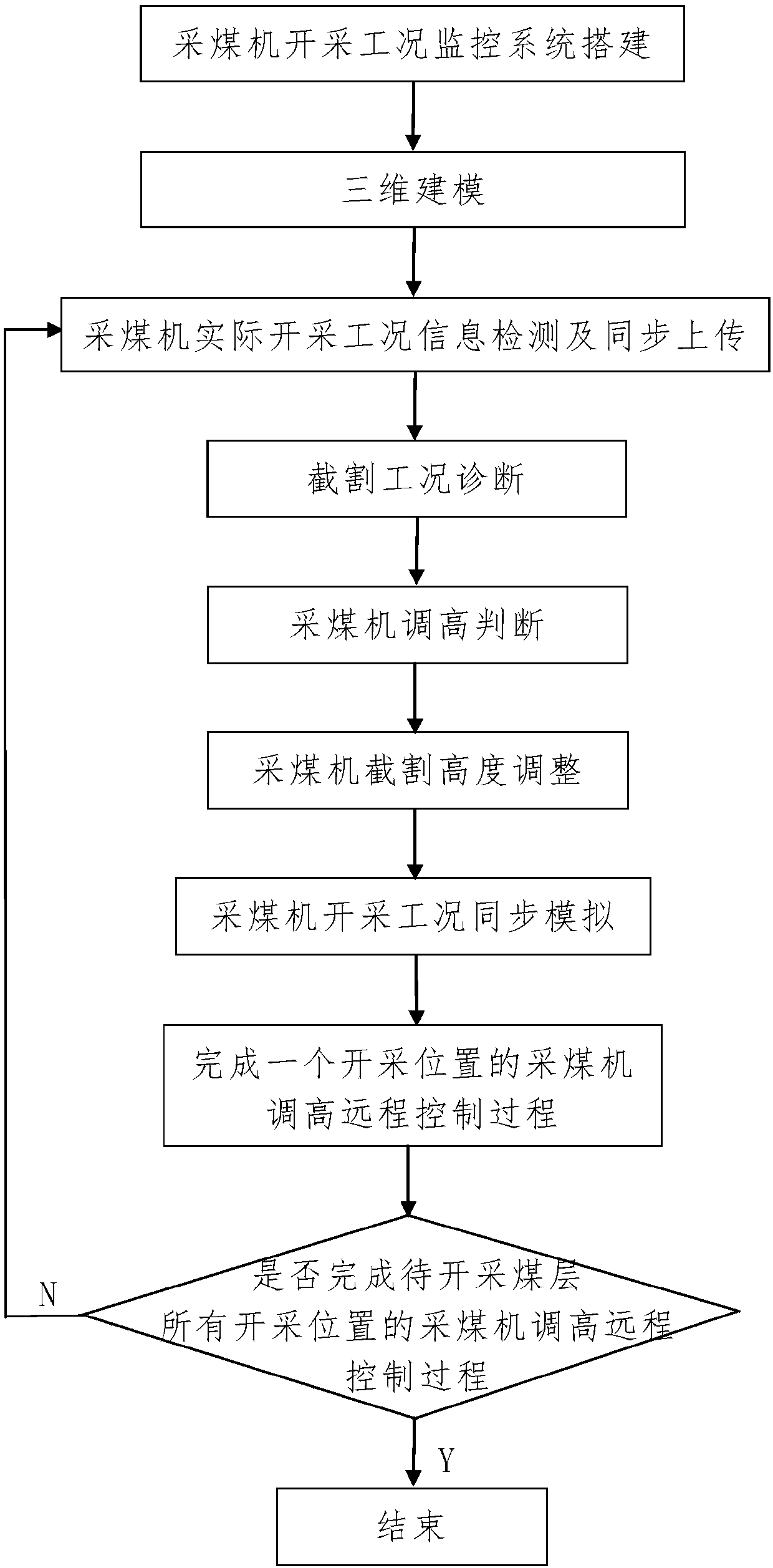

[0066] Such as figure 1 A remote control method for height adjustment of a shearer based on virtual reality is shown, including the following steps:

[0067] Step 1. Construction of the shearer mining condition monitoring system: before mining the coal seam to be mined, build the shearer mining condition monitoring system;

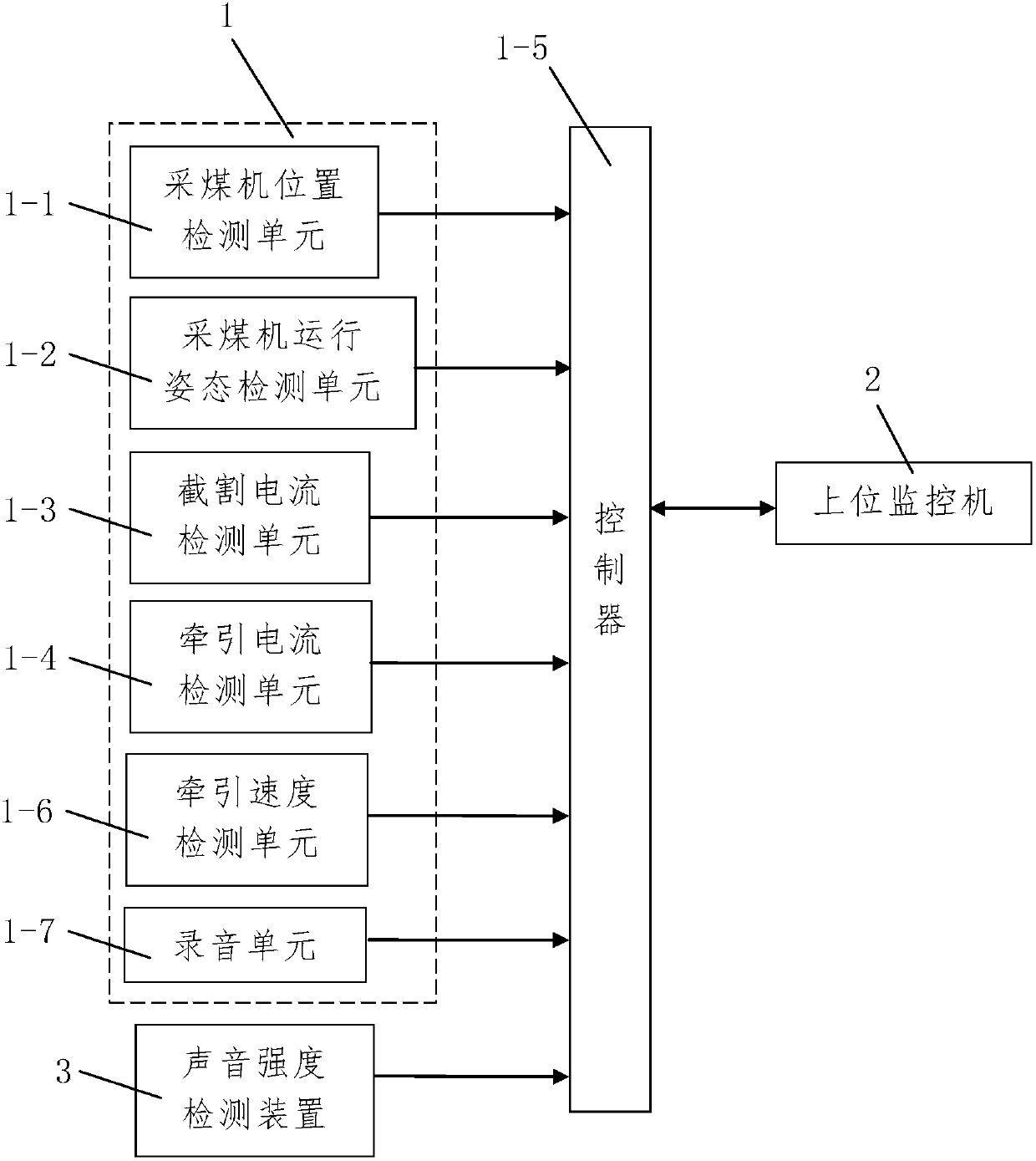

[0068] Such as image 3 As shown, the mining working condition monitoring system of the shearer includes a sound intensity detection device 3, a lower monitoring device 1 installed on the shearer, and an upper monitoring machine 2 arranged in an upper monitoring room. The sound intensity detection device 3 includes A plurality of sound intensity detection units arranged from left to right along the length direction of the working face, the plurality of sound intensity detection units are all arranged on the support of the working face, and the lower monitoring device 1 and the upper monitoring machine 2 perform two-way communication;

[0069] The shearer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com