Hydrogen-rich food making machine

A technology for food preparation and hydrogen enrichment, which is applied in the fields of food manufacturing equipment and hydrogen-rich food preparation machines, can solve the problems that the demand for hydrogen-rich food cannot be met, and there is no hydrogen-rich food preparation device, so as to avoid toxic and side effects and achieve good health care effects. , the effect of long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

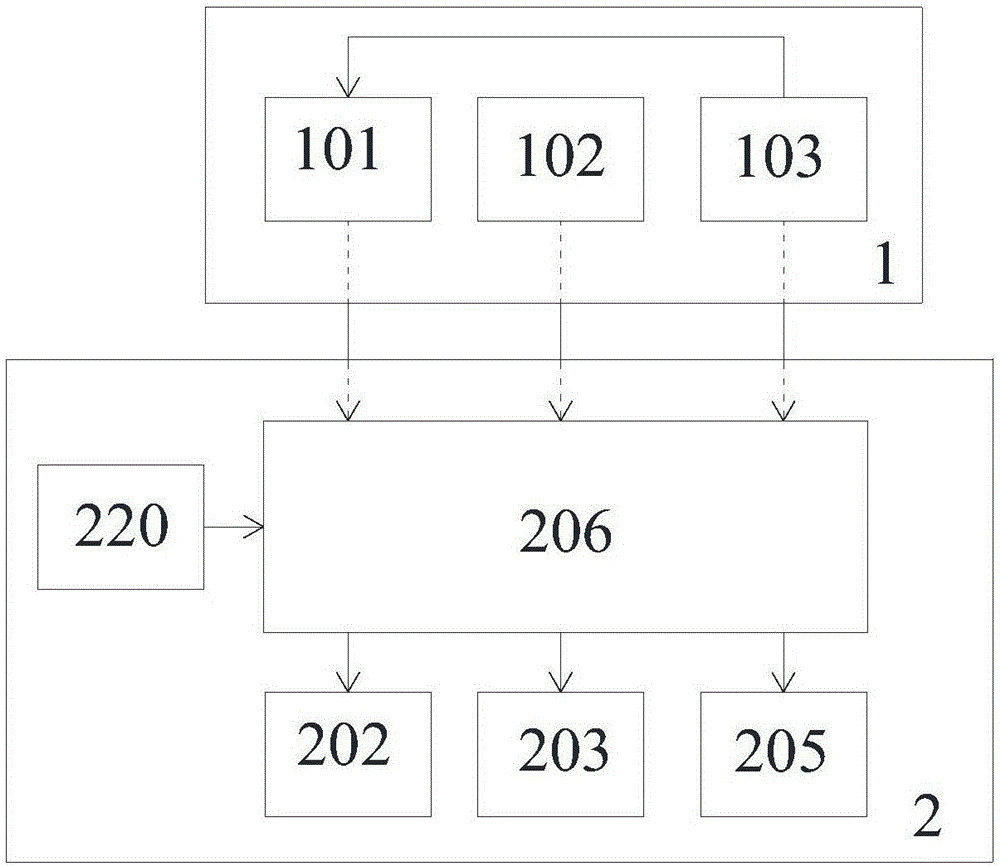

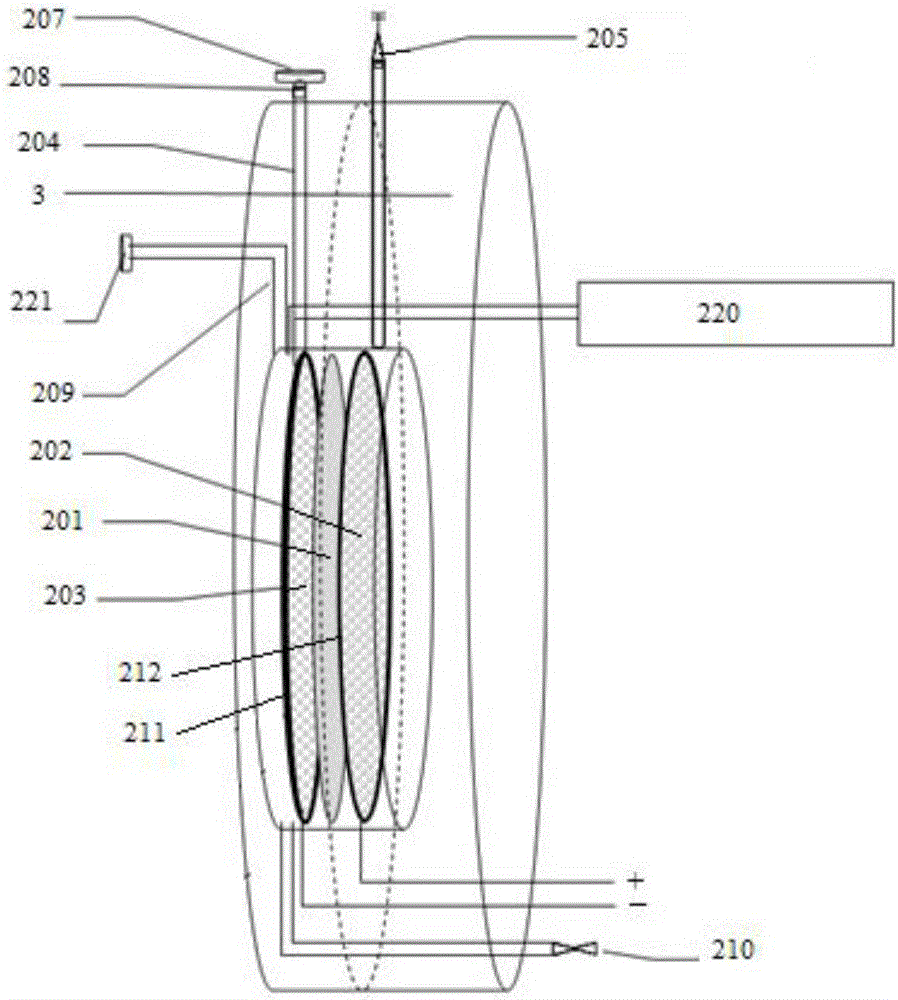

[0021] Example 1, such as figure 1 and figure 2 As shown, a hydrogen-rich food preparation machine includes a body with a food processing bin and a sealing cover fastened on the body. An electric heating element and a controller 1 are arranged in the body. The body can be an inner layer and an outer layer or an inner layer , middle and outer layers, the inner body of the body is used to hold the food to be cooked to form a food processing bin, the outer body is used to install the electric heating element and the controller 1, and at the same time play the role of safety protection and heat preservation, the three-layer body A middle warehouse body is added between the inner and outer two layers of warehouse bodies to form a steamer and play a double role of heat preservation. A parallel needle pressure relief valve is installed above the food processing chamber of the preparation machine. The gas in the food processing chamber can be discharged to the outside through the pa...

Embodiment 2

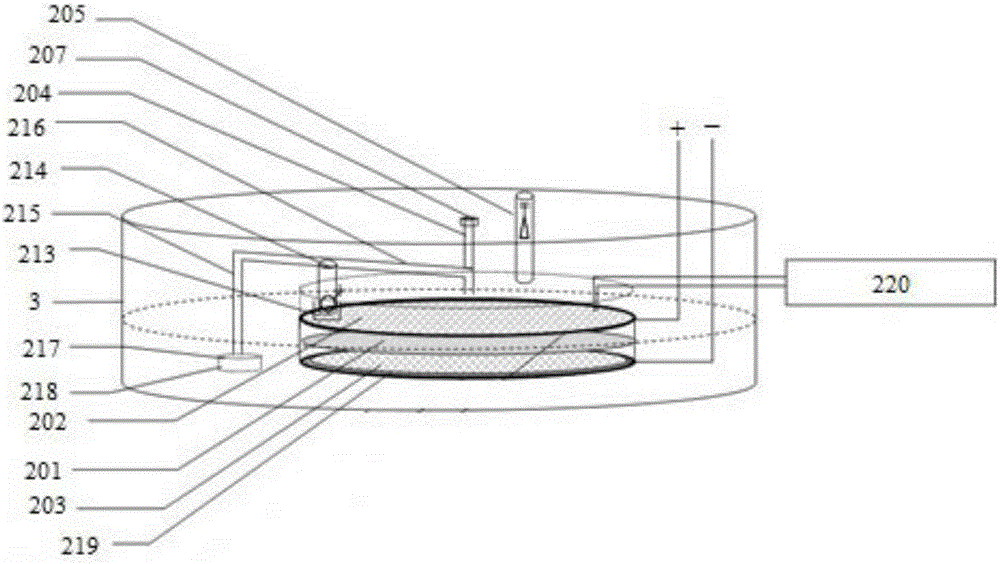

[0029] Embodiment 2, as image 3 As shown, the difference from Example 1 is that the electrolytic water hydrogen production unit 2 includes an electrolytic water supply hydrogen discharge unit. In order to further save space and make the preparation machine more neat and beautiful as a whole, the hydrogen source shell 3 is arranged inside the sealing cover and the hydrogen source The bottom plate corresponding to the inner chamber of the shell 3 is a hollow structure to form a hydrogen outlet connected to the food processing warehouse, so that the hydrogen generated in the inner chamber directly enters the food processing warehouse through the hydrogen outlet. The electrolytic water supply and hydrogen discharge unit is included in the water injection pipe 204 The quick-open sealing cover 207 provided at the entrance, the sump 213 located in the water storage space of the outer chamber and open at the bottom, the float valve 214 located in the sump 213, one end of the float val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com