PE (polyethylene) resin plastic material and preparation method thereof

A technology of stearic acid and granules, which is applied in the field of environment-friendly high thermal stability PE plastic material and its preparation, can solve the problems of thermal stability, light stability and poor interface compatibility of plastic products, and improve the interface Improvement of bonding performance, bonding performance, and poor thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

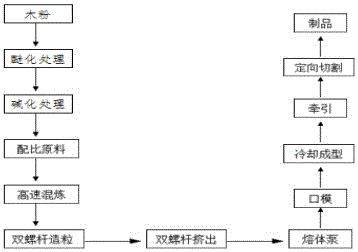

Image

Examples

Embodiment 1

[0031] Environmentally friendly high thermal stability PE plastic material, including the following components:

[0032] Wood powder particles 35kg;

[0033] Polyethylene 30kg;

[0034] Modified glass fiber 20kg;

[0035] Interface modifier WPC570D 2kg;

[0036] Stearic acid 1kg;

[0037] Polyethylene wax 2kg;

[0038] Coupling agent PE-g-MAH 3kg;

[0039] Colorant 2kg;

[0040] Chloroacetic acid solution, the concentration is 0.3mol / L;

[0041] Sodium hydroxide solution, the concentration is 0.5mol / .

[0042] The preparation method of the above-mentioned environment-friendly high thermal stability PE resin plastic material is as follows:

[0043] Step 1: Prepare 0.3mol / L chloroacetic acid solution in tank A, put the wood powder in the chloroacetic acid solution, ensure that the wood powder is completely immersed in the solution, stir and soak for 2 hours;

[0044] The second step: prepare 0.5mol / L sodium hydroxide solution in tank B, transfer the acidified wood powde...

Embodiment 2

[0055] Environmentally friendly high thermal stability PE plastic material, including the following components:

[0056] Wood powder particles 60kg;

[0057] Polyethylene 40kg;

[0058] Modified glass fiber 30kg;

[0059] Interface modifier WPC570D5kg;

[0060] Stearic acid 3kg;

[0061] Polyethylene wax 3kg;

[0062] Coupling agent PE-g-MAH5kg;

[0063] Colorant 4kg;

[0064] Chloroacetic acid solution, the concentration is 0.3mol / L;

[0065] Sodium hydroxide solution, the concentration is 0.5mol / .

[0066] The preparation method of the above-mentioned environment-friendly high thermal stability PE resin plastic material is as follows:

[0067] Step 1: Prepare 0.3mol / L chloroacetic acid solution in tank A, put the wood powder in the chloroacetic acid solution, ensure that the wood powder is completely immersed in the solution, stir and soak for 2 hours;

[0068] The second step: prepare 0.5mol / L sodium hydroxide solution in tank B, transfer the acidified wood powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com