A heat-aging-resistant, low-temperature high-impact polyphenylene ether/nylon composite material and its preparation method

A nylon composite material, heat-resistant aging technology, applied in the low-temperature high-impact polyphenylene ether/nylon composite material and its preparation, and heat-resistant aging fields, can solve the unstable performance and thermal aging of polyphenylene ether/nylon composite materials Performance and low-temperature impact performance are poor, and it cannot meet the processing requirements of thin-walled parts, etc., to achieve the effect of highlighting long-term thermal aging performance, high compatibility, and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

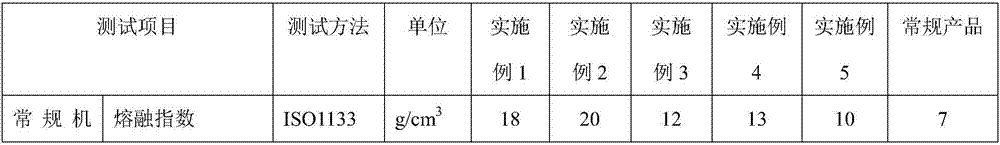

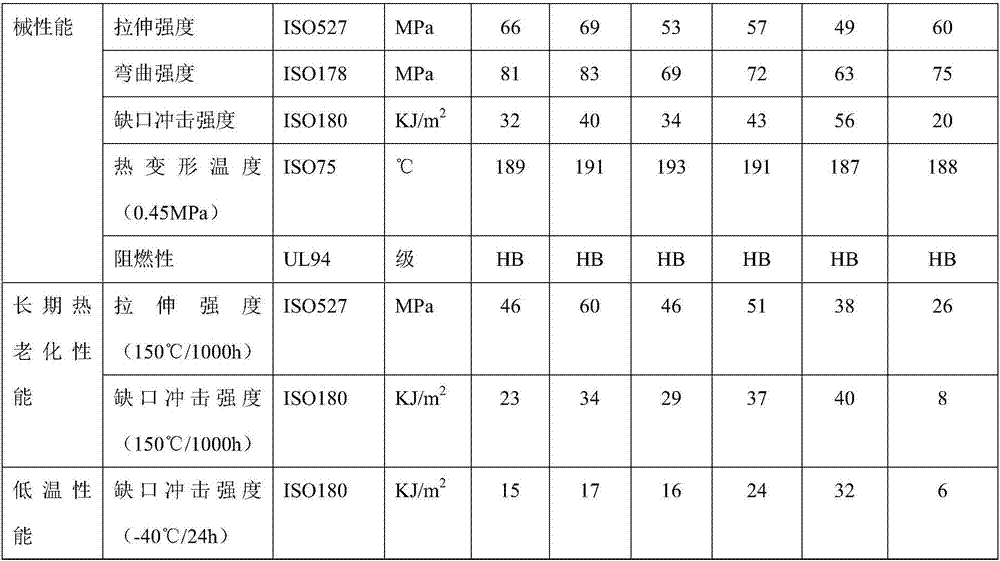

Embodiment 1

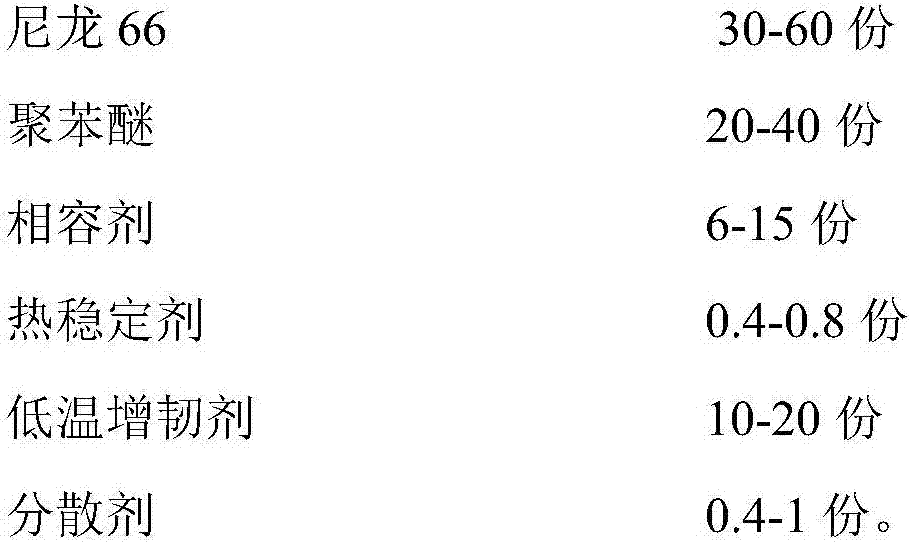

[0032] A polyphenylene ether / nylon composite material with heat aging resistance, low temperature and high impact resistance, comprising the following components in parts by weight:

[0033] The resin intrinsic viscosity of nylon 66 is: 2.2-2.45, 55.8 parts by weight;

[0034] Polyphenylene ether: 24.2 parts by weight;

[0035] Compatibilizer: styrene-maleic anhydride copolymer and maleic anhydride grafted polyphenylene ether compounded according to the weight ratio of 1:3.5, 9 parts by weight;

[0036] Heat stabilizer: a mixture of hindered phenol and phosphonate, 0.5 parts by weight in total;

[0037] Low temperature toughening agent: grafted POE, 10 parts by weight;

[0038] Dispersant: fatty acid salt, 0.5 parts by weight in total.

Embodiment 2

[0040] A polyphenylene ether / nylon composite material with heat aging resistance, low temperature and high impact resistance, comprising the following components in parts by weight:

[0041] The resin intrinsic viscosity of nylon 66 is: 2.2-2.45, 53.8 parts by weight;

[0042] Polyphenylene ether: 23.2 parts by weight;

[0043] Compatibilizer: styrene-maleic anhydride copolymer and maleic anhydride grafted polyphenylene ether are compounded according to a weight ratio of 1:5, a total of 12 parts by weight;

[0044] Heat stabilizer: copper salt compound, 0.5 parts by weight in total;

[0045] Low temperature toughening agent: grafted EPDM, 10 parts by weight;

[0046] Dispersant: fatty acid salt, a total of 0.5 parts by weight.

Embodiment 3

[0048] A polyphenylene ether / nylon composite material with heat aging resistance, low temperature and high impact resistance, comprising the following components in parts by weight:

[0049] The resin intrinsic viscosity of nylon 66 is: 2.2-2.45, 36 parts by weight;

[0050] Polyphenylene ether: 36 parts by weight;

[0051] Compatibilizer: styrene-maleic anhydride copolymer and maleic anhydride grafted polyphenylene ether are compounded according to a weight ratio of 1:5, a total of 12 parts by weight;

[0052] Heat stabilizer: copper salt compound, 0.4 parts by weight in total;

[0053] Low temperature toughening agent: grafted POE, 15 parts by weight;

[0054] Dispersant: fatty acid salt and silicone according to the ratio of 1:2, a total of 0.6 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com