Rapid cationic polymerization method for preparation of hydrophobic oleophylic composite material and application

A technology of cationic polymerization and composite materials, which is applied in the field of rapid cationic polymerization to prepare hydrophobic and lipophilic composite materials. Recycling oil and other problems to achieve good regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing hydrophobic and lipophilic composite materials by rapid cationic polymerization, comprising the following steps:

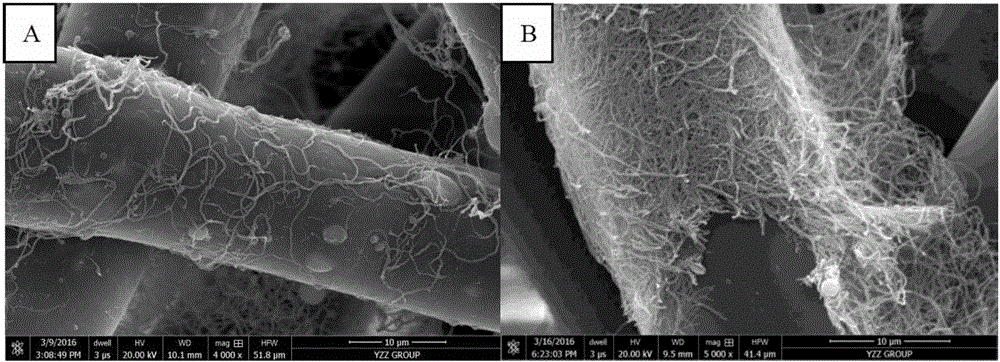

[0027] S1: Polyurethane sponge modification, add 1g of polyurethane sponge to 60ml of n-hexane solvent, and add 2ml of octadecyltrichlorosilane dropwise, stir in water bath at room temperature for 24h, take out after water bath and blow dry with N2 for use;

[0028] S2: Ultrasonic treatment, put 0.5g of modified polyurethane sponge into a 200ml round bottom flask, then add 100ml of n-hexane organic solvent, then add 100ul of boron trifluoride ether initiator, after ultrasonication for 1-2min, add divinyl The benzene monomer continued to react ultrasonically for about 30 minutes;

[0029] S3: Drying, take out the product in S2 with tweezers, rinse with absolute ethanol three times, put it in an oven for 20 minutes, and take it out to obtain a hydrophobic and lipophilic composite material.

Embodiment 2

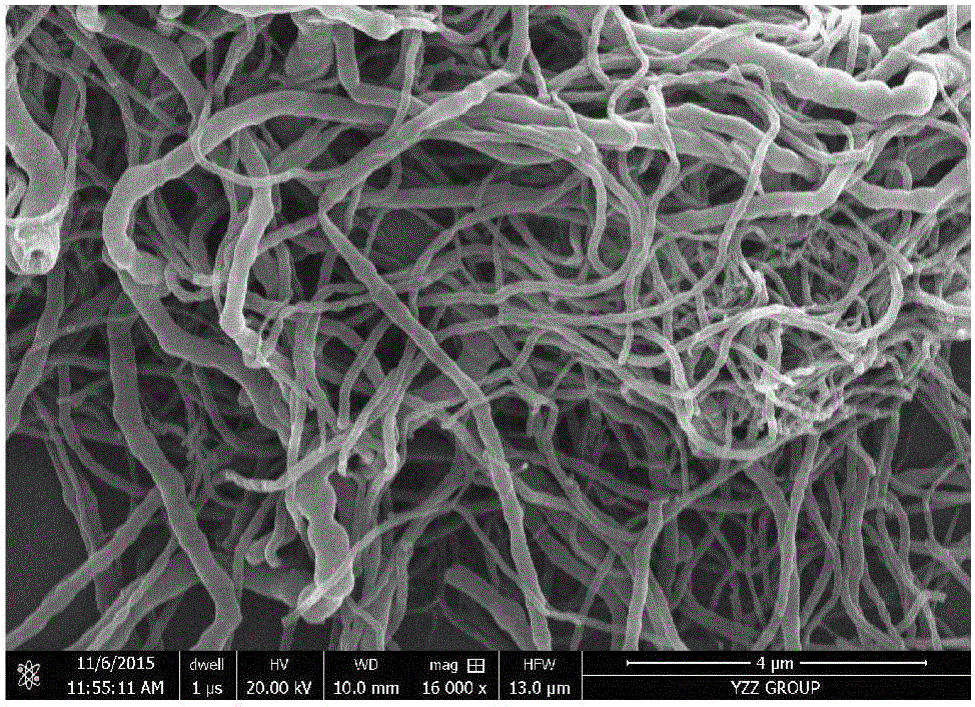

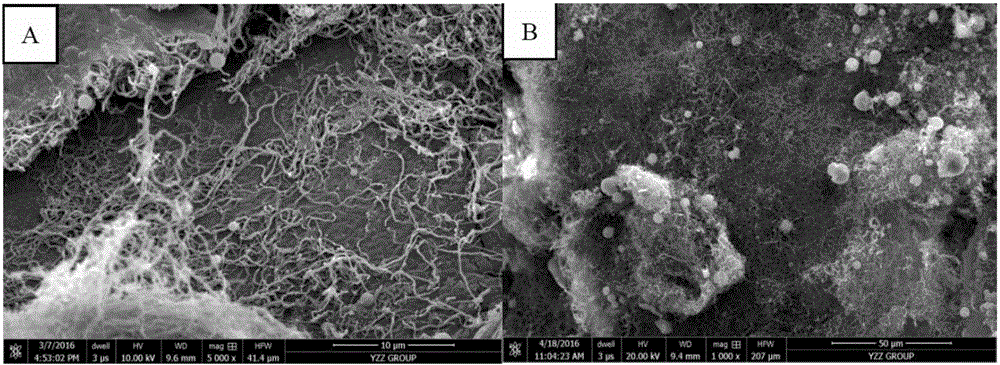

[0031] The method for preparing PDVB by rapid cationic polymerization involved in step S2 in Example 1 comprises the following steps, using n-hexane as an organic solvent, boron trifluoride ether as an initiator, adding divinylbenzene monomer after ultrasonication for a while, and then A large amount of one-dimensional nanomaterial PDVB can be obtained by continuing the ultrasonic reaction at 30°C. The divinylbenzene monomer is passed through a basic Al2O3 column to remove the tert-butylcatechol polymerization inhibitor present in the monomer.

Embodiment 3

[0033] The oil-absorbing performance test of the hydrophobic-lipophilic composite material prepared in Example 1, the hydrophobic-lipophilic composite material is used as an adsorbent for oily wastewater, and the contact angle of the polyurethane sponge is increased from 90° to 127° by a contact angle measuring instrument . Take 0.05g of hydrophobic and lipophilic composite material and put it into a small beaker filled with 10mL diesel oil, take it out after absorbing for 1min, and directly weigh the weight of the hydrophobic and lipophilic composite material that is full of oil, and finally calculate the adsorption capacity of the hydrophobic and lipophilic composite material. Diesel equivalent to 40 times its own weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com