Method for synthesizing beta-iodo-nitroolefin compound

A synthetic method and technology of nitroalkenes, applied in the direction of preparation of nitro compounds, organic chemical methods, formation/introduction of nitro/nitroso groups, etc., can solve the problems of inapplicability and few reports of synthetic methods, and achieve the goal of obtaining The effect of high efficiency, good substrate adaptability and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

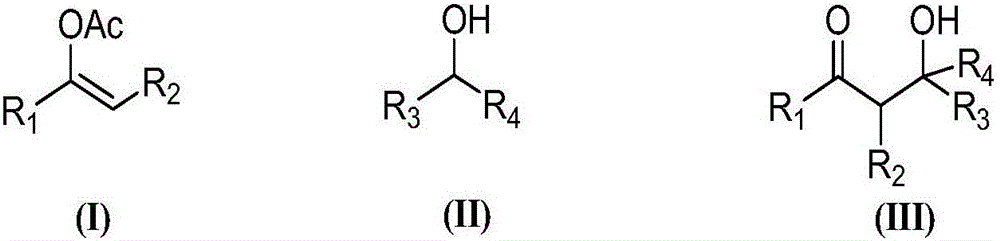

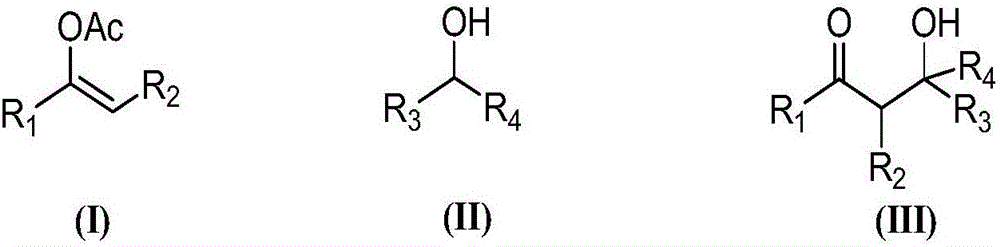

Method used

Image

Examples

Embodiment 1

[0027] Compound 1

[0028] Phenylacetylene (51mg, 0.5mmol), elemental iodine (63.5mg, 0.25mmol) and tert-butyl nitrite (103.1mg, 1mmol) were mixed in 2ml of tetrahydrofuran solvent and added to the flask, and reacted at 50°C for 4 hours. After the reaction was detected by TLC, 111.3 mg of (1-iodo-2-nitrovinyl) benzene (compound 1) was separated by column chromatography (eluent: petroleum ether / ethyl acetate volume ratio 20:1) , yield 80.9%, E / Z, >99:1.

[0029] Product characterization: pale yellow liquid; 1 H NMR (500MHz, CDCl3) δ7.63 (s, 1H), 7.34–7.26 (m, 3H), 7.25–7.19 (m, 2H). 13 C NMR (125MHz, CDCl3) δ142.18, 137.44, 127.56, 127.52, 126.25, 112.77.

Embodiment 2

[0031] Compound 1

[0032] Phenylacetylene (51mg, 0.5mmol), elemental iodine (127mg, 0.5mmol) and tert-butyl nitrite (103.1mg, 1mmol) were mixed in 2ml of tetrahydrofuran solvent and added to the flask, and reacted at 50°C for 4 hours. After the reaction was detected by TLC, 112.4mg of (1-iodo-2-nitrovinyl)benzene (compound 1) was separated by column chromatography (eluent: petroleum ether / ethyl acetate volume ratio 20:1) , yield 81.7%, E / Z, >99:1.

[0033] Product characterization: light yellow liquid; detected by TLC, the rf value is 0.26, which is the same as the rf value of compound 1 obtained in Example 1.

Embodiment 3

[0035] Compound 1

[0036] Phenylacetylene (51mg, 0.5mmol), elemental iodine (63.5mg, 0.25mmol) and tert-butyl nitrite (257.8mg, 2.5mmol) were mixed in 2ml of tetrahydrofuran solvent and added to the flask, and reacted at 50°C for 4 hours. After the reaction was detected by TLC, 108.7 mg of (1-iodo-2-nitrovinyl) benzene (compound 1) was separated by column chromatography (eluent: petroleum ether / ethyl acetate volume ratio 20:1) , yield 79.1%, E / Z, >99:1.

[0037] Product characterization: light yellow liquid; detected by TLC, compared with compound 1 obtained in Example 1, the rf value is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com