Low-cost tundish dry material with better steel slag penetration resistance and preparation method of low-cost tundish dry material

A permeable and low-cost technology, applied in the field of amorphous refractories, can solve problems such as increasing production costs, and achieve the effects of promoting reaction, improving resistance to steel slag corrosion, and improving medium temperature strength and steel slag corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

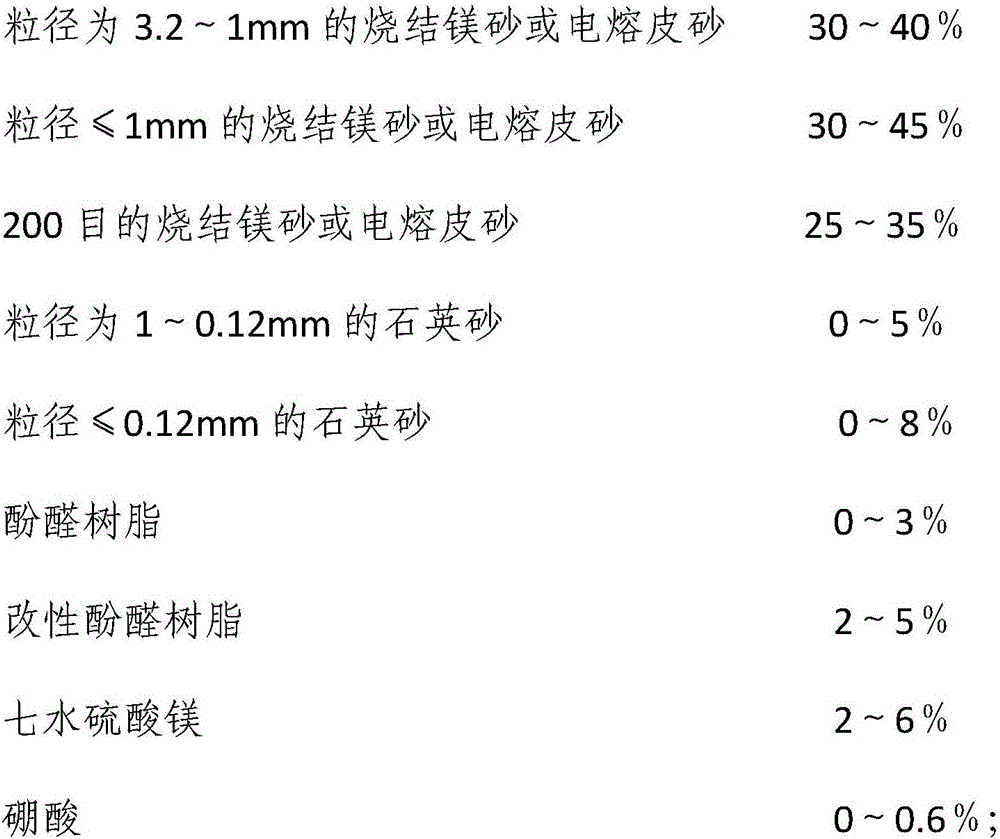

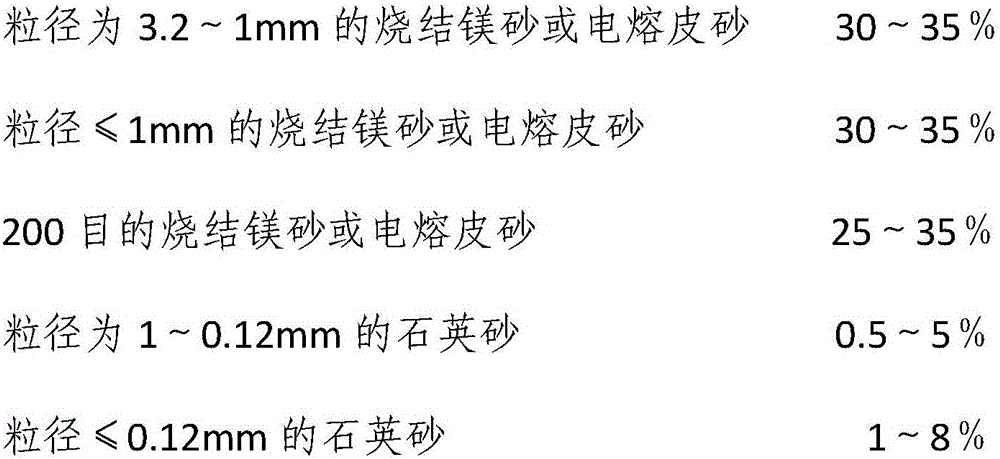

[0032] 1) Raw material formula: the unit is parts by weight

[0033]

Example 1

Example 2

Example 3

Example 4

Example 5

Sintered magnesia or fused leather sand with a particle size of 3.2-1mm

32

30

35

30

34

Sintered magnesia or fused leather sand with a particle size of ≤1mm

30

31

26

36

30

200 mesh sintered magnesia or fused leather sand

23

25.5

23.5

23

18

Quartz sand with a particle size of 1-0.12mm

5

3

6

4

0

Quartz sand with particle size ≤0.12mm

3

3

0

0

8

Phenolic Resin

1.5

1

0

2

1

Modified phenolic resin

3

3

5

2

4

Magnesium Sulfate Heptahydrate

2

3

4

3

5

0.5

0.5

0.5

0

0

[0034] 2) The preparation method of the dry formula:

[0035] ⑴Process sintered magnesia into three particle size specifications: 3.2~1mm, ≤1mm and 200 mesh;

[0036]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com