Production process of stable-phase and stable-amplitude cable

A production process and cable technology, applied in the field of production process of stable phase and amplitude cables, can solve the problems of poor modification effect, large temperature difference, uncontrollable ambient temperature, etc., to improve the performance of stable phase and amplitude and the shielding effect, Small deformation, the effect of preventing bending and squeezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

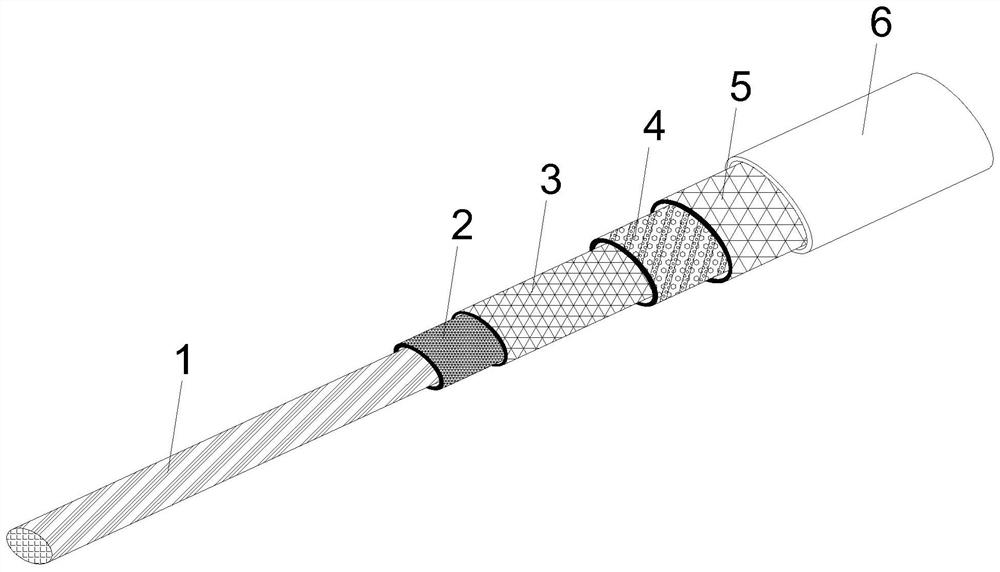

[0017] Embodiment 1: as figure 1 As shown, the present invention provides a production process for a stable phase and amplitude cable. The cable includes a silver-plated copper central conductor 1, and the silver-plated copper central conductor 1 is wrapped with a polytetrafluoroethylene wrapping insulating medium layer 2. The polytetrafluoroethylene After wrapping the insulating medium layer 2 wrapped with ethylene, heat it in a high-temperature box for instantaneous thermal shock, that is, the ambient temperature is instantly raised to 140°C-160°C, and kept for 8-10 hours; wrap the insulating medium layer 2 with polytetrafluoroethylene The silver-plated copper wrapping process is performed on the outside to form the inner shielding layer 3, and then the microporous silver tape layer 4 is wrapped. After the microporous silver tape layer 4 is wrapped, the silver-plated copper wire outer shielding layer 5 is braided, and then put The high-temperature box undergoes another insta...

Embodiment 2

[0018] Embodiment 2: A production process of a stable phase and amplitude cable, the cable includes a silver-plated copper central conductor 1, and the silver-plated copper central conductor 1 is wrapped with a polytetrafluoroethylene wrapping insulating medium layer 2, and the polytetrafluoroethylene is wound After wrapping the insulating medium layer 2, heat it in a high-temperature box for instantaneous thermal shock, that is, to instantly raise the ambient temperature to 140°C-160°C, and keep it warm for 8-10 hours; The silver-plated copper wrapping process forms the wrapping of the inner shielding layer 3 and the microporous silver tape layer 4. After wrapping, it is placed in a high-temperature box for another instantaneous thermal shock, that is, the ambient temperature is instantly raised to 100°C~120°C, and the holding time For 4 to 6 hours; carry out the weaving of the outer shielding layer 5 of silver-plated copper wire on the outside of the microporous silver tape l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com