A kind of ti-al intermetallic compound micro-laminated composite armor and its preparation method

A technology of intermetallic compounds and micro-lamination, which is applied to the structure of armor, protective equipment, armor plates, etc., can solve the problems of low hardness, plastic deformation, etc., and achieve high interface bonding strength, integrity maintenance, and good penetration ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

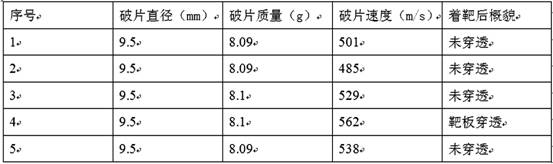

Examples

Embodiment 1

[0038] Embodiment 1: A kind of Ti-Al intermetallic compound micro-lamination composite armor, described Ti-Al intermetallic compound micro-lamination composite armor is made of Ti-AlTi and Ti-Al 3 Ti-Al intermetallic compound micro-laminated composite armor composed of Ti-Al laminated composite materials, in which: Ti-AlTi laminated composite material is used as the armor front plate, Ti-Al 3 The Ti-Al laminated composite material is used as the armored rear plate, and the armored front plate and the armored rear plate are connected by diffusion welding; the thickness ratio of the armored front plate to the armored rear plate is 3:1.

[0039] The specific preparation method of Ti-AlTi laminated composite material is as follows:

[0040] (1) Acid and alkali cleaning TC 4 , Al foil: 0.15mm thick TC 4 Foil, 0.1mm thick Al foil is cut according to the size of 100×100mm; the cut TC 4 The foil was treated in an acid solution prepared by HF and water at a volume ratio of 1:20, and...

Embodiment 2

[0061] Embodiment 2: The difference between this embodiment and specific embodiment 1 is: TC 4 The thickness of the foil is 0.3 mm, the thickness of the Al foil is 0.2 mm, and other steps and parameters are the same as those in the first embodiment.

Embodiment 3

[0062] Example 3: The difference between this embodiment and the first embodiment is that the highest temperature for preparing the Ti-AlTi laminated composite material is 1300° C., and other steps and parameters are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com