Homogenous magnesian gelling material, and preparation method and product thereof

A technology of magnesium gelling materials and reinforcing materials, which is applied in the field of building materials, can solve the problems of endangering the personal health of production workers, itchy skin, and diffuse dust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0117] Correspondingly, the present invention also provides a method for preparing a homogeneous magnesia gelling material, comprising the following steps:

[0118] (1) Mix the raw materials according to the formula and stir to make a slurry.

[0119] Before mixing, the bamboo silk is pretreated by high-temperature cooking, bleaching and carbonization, and then the bamboo bran is removed with a 10-mesh sieve. Choose dry bamboo filaments with low moisture content, the length of which is ≤15mm, and the diameter of the filaments is ≤1.5mm.

[0120] It should be noted that the bamboo shreds should be added in the final stage of mixing and dispersed evenly.

[0121] (2) Apply mold release liquid to the mold, introduce the slurry into the mold, and comb it flat.

[0122] (3) Lay non-woven fabric on the surface of the slurry, and make the slurry compact by rolling.

[0123] (4) Let it stand until the slurry is hardened, and demould.

[0124] (5) Remove the non-woven fabric on the...

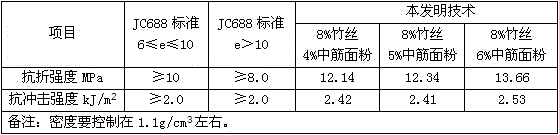

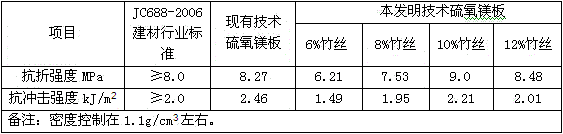

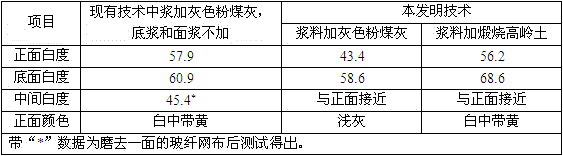

Embodiment 1

[0128] By weight, 120 parts of magnesium sulfate solution, 100 parts of magnesium oxide, 1 part of magnesium oxysulfide modifier, 10 parts of fly ash, 5 parts of silica fume, 2.8 parts of perlite, 12.3 parts of wood bran and 4 parts of 10% concentration For AC foaming liquid mixing, add 12 parts of bamboo silk in the final stage of mixing, and make a slurry after dispersing evenly; apply mold release liquid to the formwork, and introduce the slurry into the mold plate In the middle, comb flat; lay non-woven fabric on the surface of the slurry, and make the slurry compact by rolling. Let it stand until the slurry is hardened, demoulding; trimming , Remove the non-woven fabric on the surface through surface sanding, check, repair, and maintain to obtain a magnesium oxysulfide flat plate with a thickness of 12mm.

Embodiment 2

[0130] By weight, 122 parts of magnesium sulfate solution, 100 parts of magnesium oxide, 1 part of magnesium oxysulfide modifier, 9 parts of fly ash, 6 parts of silica fume, 2.9 parts of perlite, 11.7 parts of wood bran, 3 parts of all-purpose flour and Mix 5 parts of 10% concentration AC foaming liquid, add 8 parts of bamboo silk in the final stage of mixing, and disperse evenly to make slurry; apply mold release liquid to the formwork, and introduce the slurry into the formwork, Comb flat; lay non-woven fabric on the surface of the slurry, and roll to make the slurry compact. Let it stand until the hardening of the slurry is completed, and demould; after stripping and curing, a magnesium oxysulfide door core board with a thickness of 9mm is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com