A concrete salt erosion transmission inhibition material in saline-alkali areas

A concrete and regional technology, applied in the field of inhibiting concrete salt erosion hazards in saline-alkali areas, can solve problems such as concrete salt erosion hazards, achieve the effects of inhibiting salt erosion, improving chemical stability and durability, and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

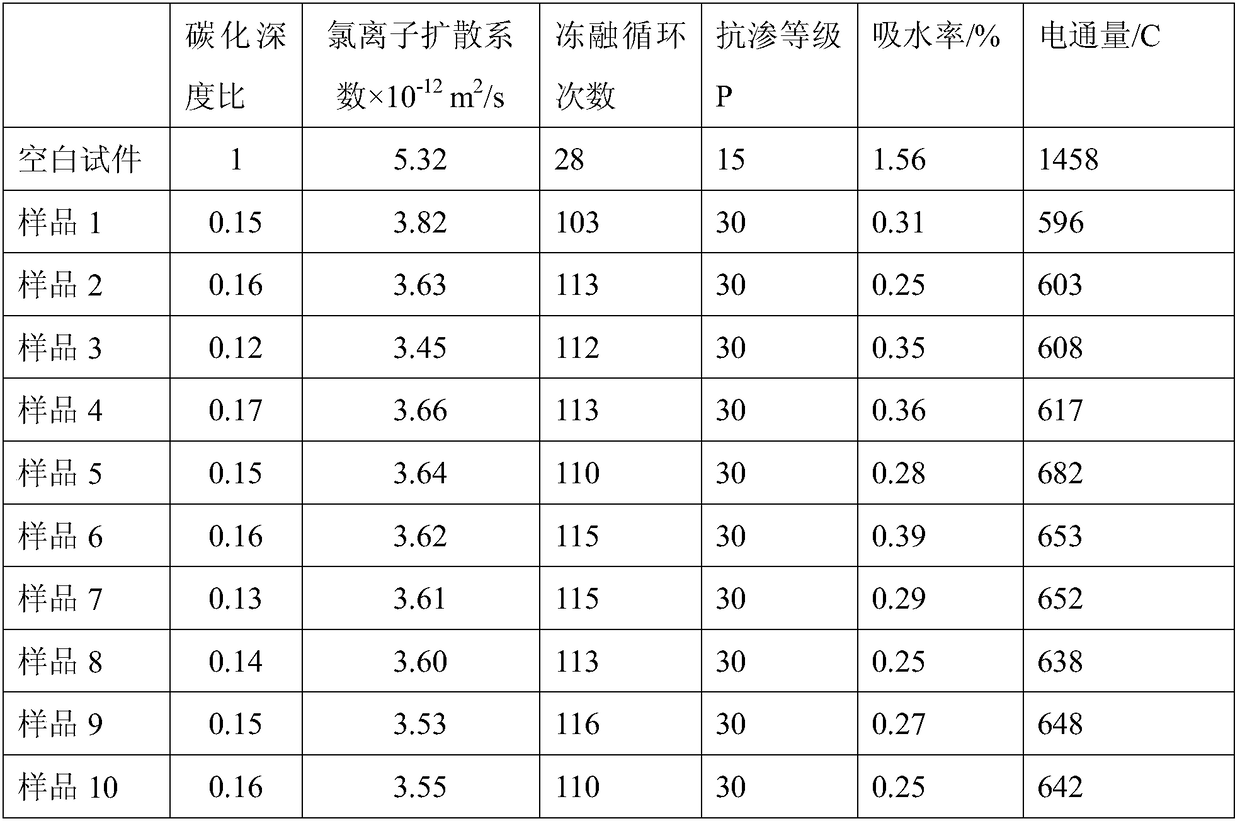

Examples

Embodiment 1

[0025] 1) Preparation of epoxy-modified polysiloxane: Weigh 60g of hydrogenated bisphenol A epoxy resin and 40g of polymethylphenylsiloxane and place them in eggplant-shaped bottles, and rotatively evaporate at 80°C for 30min to remove A small amount of moisture contained in the raw material is cooled to room temperature and set aside. Add 60g of hydrogenated bisphenol A type epoxy resin and 40g of polymethylphenylsiloxane into a three-necked flask equipped with mechanical stirring, adding funnel, and reflux condenser, stir and heat up to 80°C, then add dilaurel dropwise Acetate dibutyltin, continue to heat up to 140 ° C, and stir at constant temperature for 3.5 hours to obtain a transparent viscous liquid.

[0026] 2) Preparation of polypropylmethylsilsesquioxane: Add 140ml of methyltriethoxysilane and 60ml of propyltriethoxysilane into a 1000mL three-necked bottle equipped with a stirrer, reflux condenser and thermometer , 0.0.1mol / L hydrochloric acid 20mL, isopropanol 100....

Embodiment 2

[0029] 1) Preparation of epoxy-modified polysiloxane: Weigh 60g of hydrogenated bisphenol A epoxy resin and 40g of polymethylphenylsiloxane and place them in eggplant-shaped bottles, and rotatively evaporate at 80°C for 30min to remove A small amount of moisture contained in the raw material is cooled to room temperature and set aside. Add 60g of hydrogenated bisphenol A type epoxy resin and 40g of polymethylphenylsiloxane into a three-necked flask equipped with mechanical stirring, adding funnel, and reflux condenser, stir and heat up to 80°C, then add dilaurel dropwise Acetate dibutyltin, continue to heat up to 140 ° C, and stir at constant temperature for 3.5 hours to obtain a transparent viscous liquid.

[0030] 2) Preparation of polypropylmethylsilsesquioxane: Add 140ml of methyltriethoxysilane and 65ml of propyltriethoxysilane into a 1000mL three-necked bottle equipped with a stirrer, reflux condenser and thermometer , 0.0.1mol / L hydrochloric acid 20mL, isopropanol 100....

Embodiment 3

[0033] 1) Preparation of epoxy-modified polysiloxane: Weigh 60g of hydrogenated bisphenol A epoxy resin and 40g of polymethylphenylsiloxane and place them in eggplant-shaped bottles, and rotatively evaporate at 80°C for 30min to remove A small amount of moisture contained in the raw material is cooled to room temperature and set aside. Add 60g of hydrogenated bisphenol A type epoxy resin and 40g of polymethylphenylsiloxane into a three-necked flask equipped with mechanical stirring, adding funnel, and reflux condenser, stir and heat up to 80°C, then add dilaurel dropwise Acetate dibutyltin, continue to heat up to 140 ° C, and stir at constant temperature for 3.5 hours to obtain a transparent viscous liquid.

[0034] 2) Preparation of polypropylmethylsilsesquioxane: Add 140ml of methyltriethoxysilane and 60ml of propyltriethoxysilane into a 1000mL three-necked bottle equipped with a stirrer, reflux condenser and thermometer , 0.0.1mol / L hydrochloric acid 20mL, isopropanol 100....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com