Beneficiation method for low-grade difficult-to-treat scheelite

A beneficiation method and refractory technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of refractory scheelite, low-cost flotation separation, high efficiency of fluorite, etc. Significant economic benefits and good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

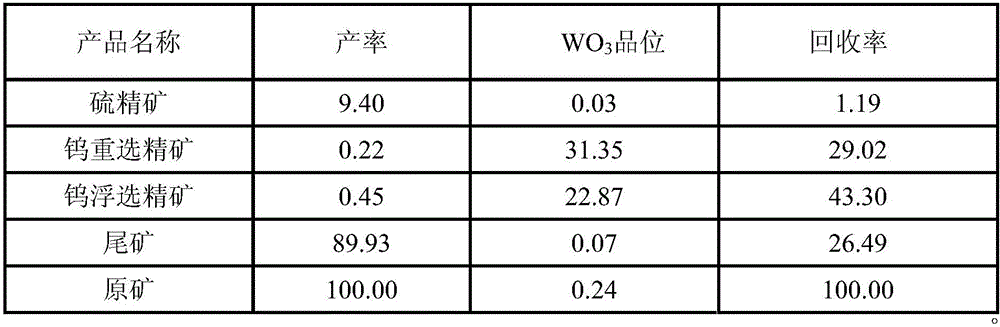

Embodiment 1

[0015] The scheelite ore is ground to -0.074mm particle size ore, accounting for 50% of the total ore mass, graded at 0.037mm, +0.037mm particle size for shaking table gravity separation, to obtain tungsten gravity separation concentrate, shaking table separation Bie tailings are ground to -0.074mm particle size ore accounting for 75% of the total ore mass percentage, mixed with -0.037mm particle size, and then adding collector butyl xanthate 60g / t, foaming agent No. 2 oil 20g / t Flotation to remove sulfide ore, add 1500g / t sodium carbonate, 3000g / t inhibitor YFW-12, and 120g / t collector BF-01 to the slurry after removing sulfide ore for roughing to obtain roughing concentrate And rougher tailings, adding 1500g / t inhibitor YFW-12 and 80g / t collector BF-01 to the rougher tailings for the first sweeping, the first sweeping returns to the rougher, the first time Add 80g / t collector BF-01 to the scavenging tailings for the second scavenging to obtain the final tailings, and return ...

Embodiment 2

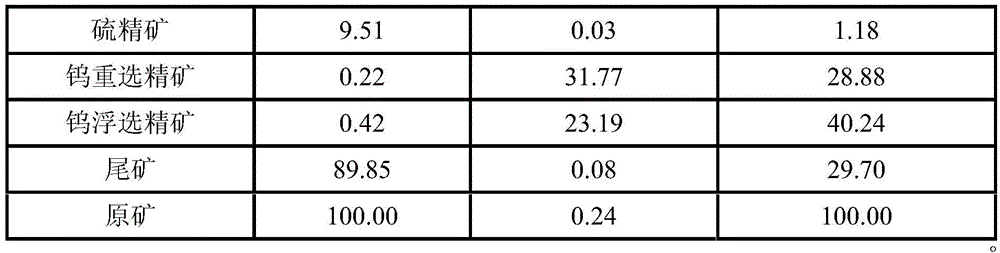

[0020] Grinding scheelite ore to -0.074mm particle size grade is 50% of the ore mass percentage, grading at 0.037mm, +0.037mm particle size for shaking table gravity separation to obtain tungsten gravity separation concentrate, shaking table separation tailings Grind to -0.074mm particle size ore mass percentage of 75%, mix with -0.037mm particle size, add collector butyl xanthate 60g / t, foaming agent No. 2 oil 20g / t flotation to remove sulfide ore , adding 1200g / t sodium carbonate, 2500g / t inhibitor YFW-12, and 150g / t collector BF-01 to the slurry after removing sulfide ore for roughing to obtain roughing concentrate and roughing tailings, Add 1200g / t inhibitor YFW-12 and 80g / t collector BF-01 to the roughing tailings for the first scavenging, and return to roughing for the first scavenging, and add 80g / t to the scavenging tailings to capture Collector BF-01 is used for the second sweeping to obtain the final tailings, and the second sweeping returns to the first sweeping. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com