Heavy metal ion adsorbent and preparation method and application thereof

A technology for heavy metal ions and adsorbents, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of inability to achieve continuous treatment, severe decline in adsorption performance, complex synthesis process, etc., and achieve the adsorption rate. The effect of fast, simple regeneration process and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

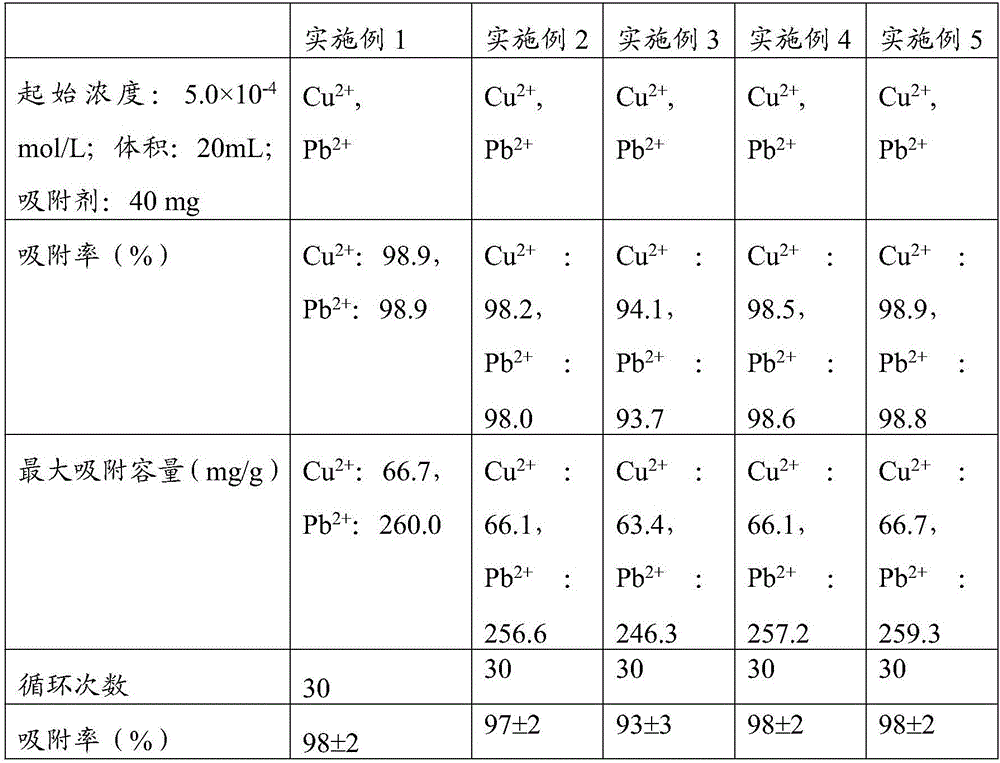

Embodiment 1

[0035] A kind of preparation method of heavy metal ion adsorbent:

[0036] (1) Weigh 0.3g of mesoporous molecular sieve (SBA-15) and disperse it in 50mL of water, add 0.2mL of 3-aminopropyltrimethoxysilane under stirring condition, react at 25℃ for 4h, filter, and wash with acetone successively Wash with distilled water and dry at 40°C to obtain amino-modified SBA-15;

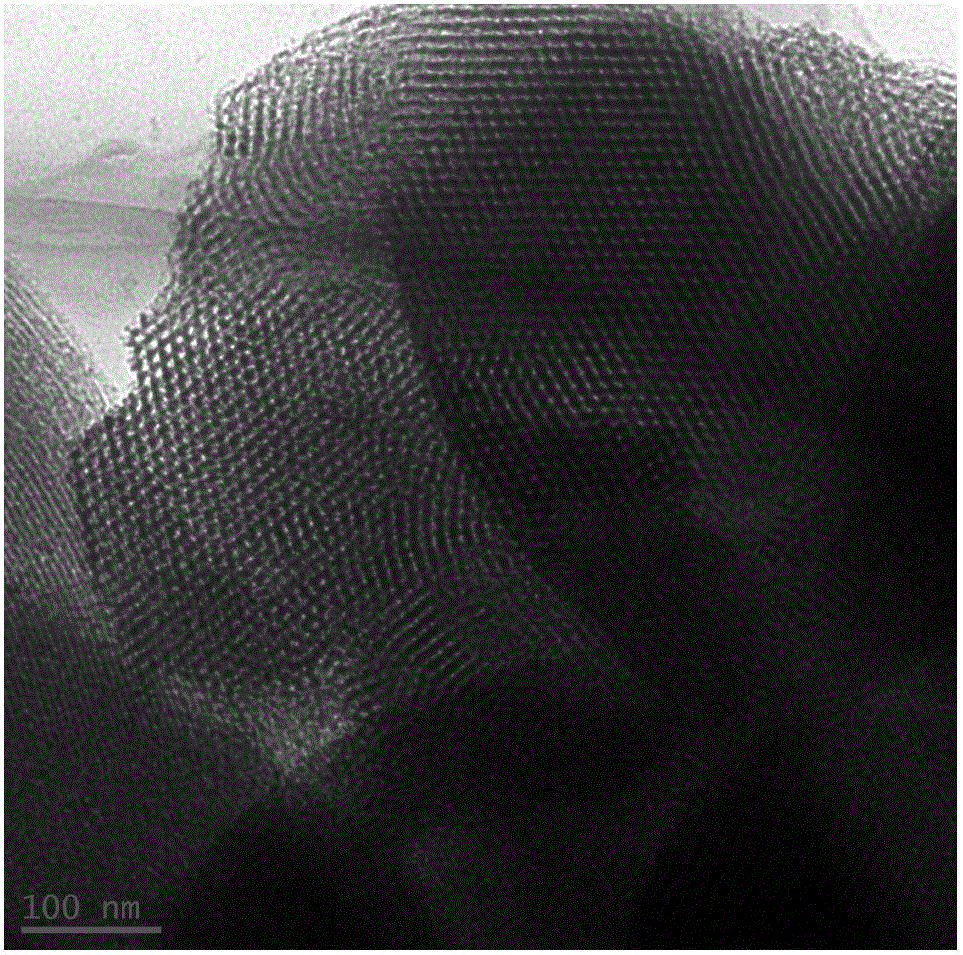

[0037] (2) Weigh 0.5g of sodium alginate and dissolve it in 50mL of water, add 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride for activation for 1 hour, and add amino-modified SBA-15 was reacted at 25°C for 4 hours, filtered, washed with acetone and distilled water successively, and dried at 40°C to obtain a heavy metal ion adsorbent. The transmission electron microscope image of the heavy metal ion adsorbent is shown in figure 1 shown.

Embodiment 2

[0039] A kind of preparation method of heavy metal ion adsorbent:

[0040] (1) Weigh 0.3g of mesoporous molecular sieve (MCM-41) and disperse it in 50mL of water, add 0.2mL of 3-aminopropyltrimethoxysilane under stirring condition, react at 25℃ for 4h, filter, and wash with acetone successively Wash with distilled water and dry at 40°C to obtain amino-modified SBA-15;

[0041](2) Weigh 0.5g of sodium alginate and dissolve it in 50mL of water, add 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride for activation for 1 hour, and add amino-modified SBA-15 was reacted at 25°C for 4 hours, filtered, washed with acetone and distilled water successively, and dried at 40°C to obtain a heavy metal ion adsorbent.

[0042] The difference between Example 2 and Example 1 is that the mesoporous molecular sieve (SBA-15) is replaced by mesoporous molecular sieve (MCM-41).

Embodiment 3

[0044] A kind of preparation method of heavy metal ion adsorbent:

[0045] (1) Weigh 0.3g of 100-120 mesh silica gel and disperse it in 50mL of water, add 0.2mL of 3-aminopropyltrimethoxysilane under stirring condition, react at 25°C for 4h, filter, wash with acetone and distilled water successively , dried at 40°C to obtain amino-modified SBA-15;

[0046] (2) Weigh 0.5g of sodium alginate and dissolve it in 50mL of water, add 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride for activation for 1 hour, and add amino-modified SBA-15 was reacted at 25°C for 4 hours, filtered, washed with acetone and distilled water successively, and dried at 40°C to obtain a heavy metal ion adsorbent.

[0047] The difference between Example 3 and Example 1 is that the mesoporous molecular sieve (SBA-15) is replaced by 100-120 mesh silica gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com