Preparation method for lithium-rich manganese-based positive electrode material coated by phosphate polyanion composite manganese salt

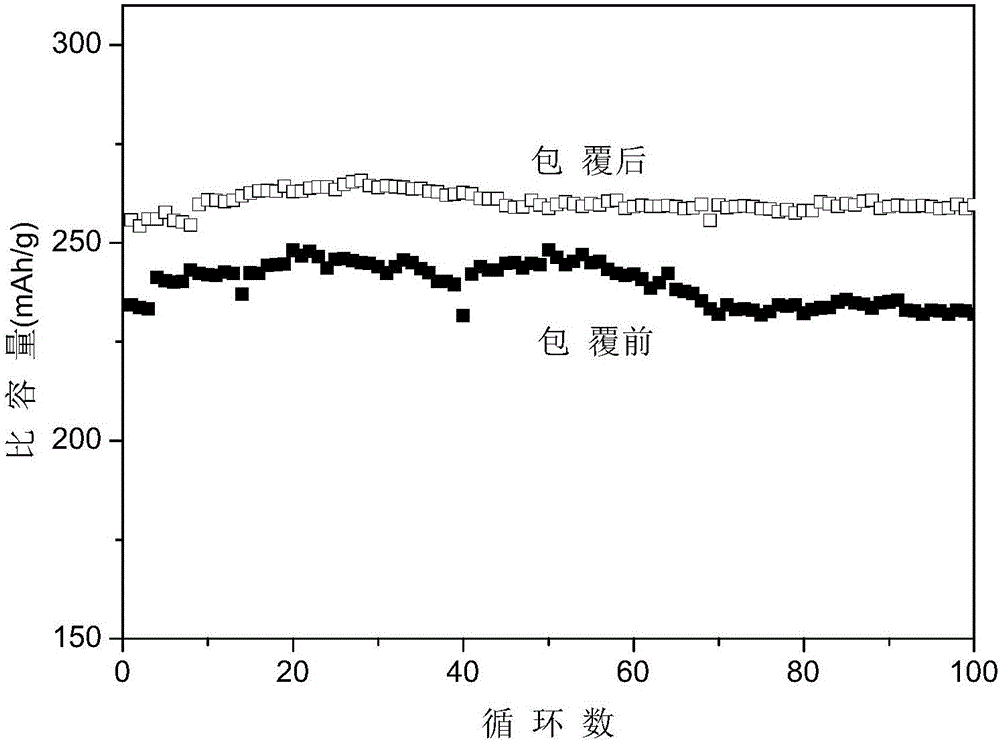

A lithium-rich manganese-based, polyanion technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor rate performance and cycle performance of lithium-rich manganese-based positive electrode materials, and achieve improved electrical conductivity and ionization. Effects of transport performance, enhanced electrochemical performance, and improved cycle and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a lithium-rich manganese-based positive electrode material coated with a phosphate polyanion composite manganese salt, comprising the following steps:

[0030] Step 1) The lithium-rich manganese-based cathode material used has a molecular formula of 0.5Li 2 MnO 3 0.5LiNi 0.4 mn 0.4 co 0.2 o 2 .

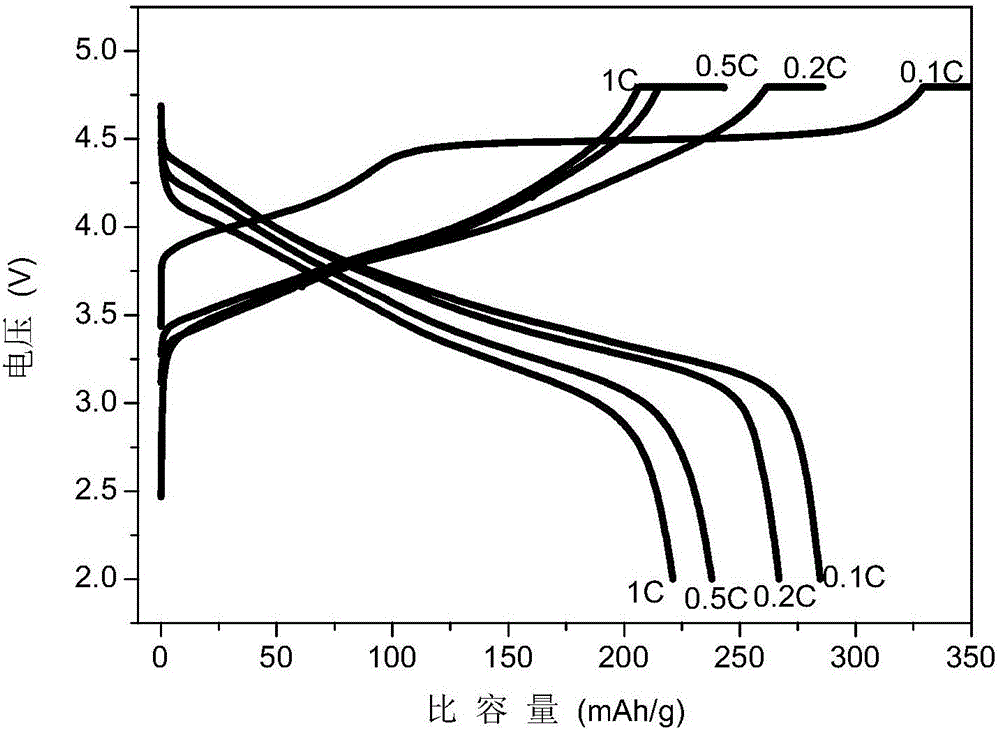

[0031] Step 2) 3wt% phosphate polyanion composite manganese salt coated lithium-rich manganese-based positive electrode material 0.5Li 2 MnO 3 0.5LiNi 0.4 mn 0.4 co 0.2 o 2 preparation of

[0032] According to the Mn:P molar ratio of 1:1, weigh 0.1021g of manganese acetate and 0.0479g of ammonium dihydrogen phosphate and dissolve them in 50mL of deionized water successively, add 0.2mol / L citric acid aqueous solution dropwise to adjust pH=4, and stir for 0.5 hours; according to the coating amount of 3wt% phosphate polyanion composite manganese salt, 5g of lithium-rich manganese-based positive electrode material should be added to the above solu...

Embodiment 2

[0037] A method for preparing a lithium-rich manganese-based positive electrode material coated with a phosphate polyanion composite manganese salt, comprising the following steps:

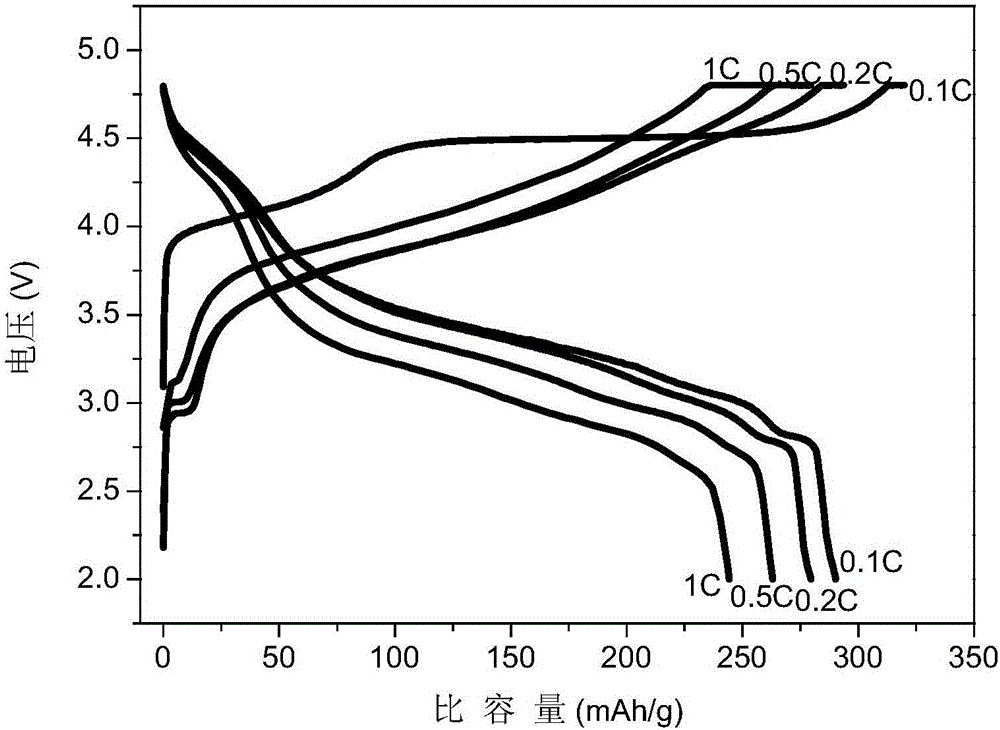

[0038] Step 1) The lithium-rich manganese-based cathode material used has a molecular formula of 0.5Li 2 MnO 3 0.5LiNi 0.4 mn 0.4 co 0.2 o 2 .

[0039] Step 2) 5wt% phosphate polyanion composite manganese salt coated lithium-rich manganese-based positive electrode material 0.5Li 2 MnO 3 0.5LiNi 0.4 mn 0.4 co 0.2 o 2 preparation of

[0040] According to the Mn:P molar ratio of 2:1, weigh 0.2025g of manganese acetate and 0.0475g of ammonium dihydrogen phosphate and dissolve them in 50mL of deionized water successively, add 0.2mol / L citric acid aqueous solution dropwise to adjust pH=5, and stir for 0.5 Hours; according to the phosphate polyanion composite manganese salt with a coating amount of 5wt%, 5g of lithium-rich manganese-based positive electrode materials should be added to the ab...

Embodiment 3

[0042] A method for preparing a lithium-rich manganese-based positive electrode material coated with a phosphate polyanion composite manganese salt, comprising the following steps:

[0043] Step 1) The lithium-rich manganese-based cathode material used has a molecular formula of 0.5Li 2 MnO 3 0.5LiNi 0.4 mn 0.4 co 0.2 o 2 .

[0044] Step 2) 10wt% phosphate polyanion composite manganese salt coated lithium-rich manganese-based positive electrode material 0.5Li 2 MnO 3 0.5LiNi 0.4 mn 0.4 co 0.2 o 2 preparation of

[0045] According to the Mn:P molar ratio of 3:4, weigh 0.3072g of manganese acetate and 0.1925g of ammonium dihydrogen phosphate and dissolve them in 50mL of deionized water successively, add 0.2mol / L citric acid aqueous solution dropwise to adjust pH=6, and stir for 0.5 hours; according to the coating amount of 10wt% phosphate polyanion composite manganese salt, 5 g of lithium-rich manganese-based positive electrode materials should be added to the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com