Method for preparing silver nanowire-titanium dioxide composite transparent electrode and transparent electrode

A technology of silver nanowires and titanium dioxide, applied in the field of optoelectronics, can solve the problems of many process steps, poor uniformity of large area, etc., and achieve the effects of simple process, excellent electrical conductivity and transmittance, and excellent thermal and chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

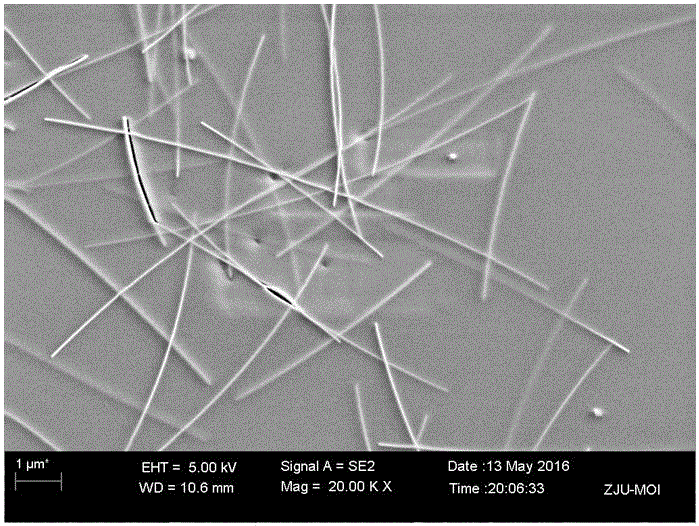

[0029] What this embodiment shows is the silver nanowire-titanium dioxide composite transparent electrode prepared on the non-flexible transparent glass substrate, and its preparation method comprises the following steps:

[0030] (1) Preparation of silver nanowire-titanium dioxide sol-gel

[0031] Take an appropriate amount of silver nanowire-ethanol suspension, wherein the concentration of silver nanowires is 2.5 mg / mL (those skilled in the art can also use other concentrations in the range of 2-4 mg / mL), and add tetraisopropyl alcohol in a certain volume ratio Titanium alkoxide and ethanolamine, vibrate until the silver nanowires are evenly dispersed therein, forming silver nanowires-titanium dioxide sol-gel, wherein the volume ratio of silver nanowires-ethanol suspension, titanium tetraisopropoxide, and ethanolamine is 8:1:0.1 (Those skilled in the art can also adopt other volume ratios in the range of 5:1:1-10:1:0.01);

[0032] (2) Prepare the transparent substrate

[0...

Embodiment 2

[0040] What this embodiment shows is the silver nanowire-titanium dioxide composite transparent electrode prepared on the flexible transparent polyethylene substrate, and its preparation method comprises the following steps:

[0041] (1) Preparation of silver nanowire-titanium dioxide sol-gel

[0042] Take an appropriate amount of silver nanowire-ethanol suspension, wherein the concentration of silver nanowires is 2.5 mg / mL (those skilled in the art can also use other concentrations in the range of 2-4 mg / mL), and add tetraisopropyl alcohol in a certain volume ratio Titanium alkoxide and ethanolamine, vibrate until the silver nanowires are evenly dispersed therein, forming silver nanowires-titanium dioxide sol-gel, wherein the volume ratio of silver nanowires-ethanol suspension, titanium tetraisopropoxide, and ethanolamine is 8:1:0.1 (Those skilled in the art can also adopt other volume ratios in the range of 5:1:1-10:1:0.01);

[0043] (2) Prepare the transparent substrate

[...

PUM

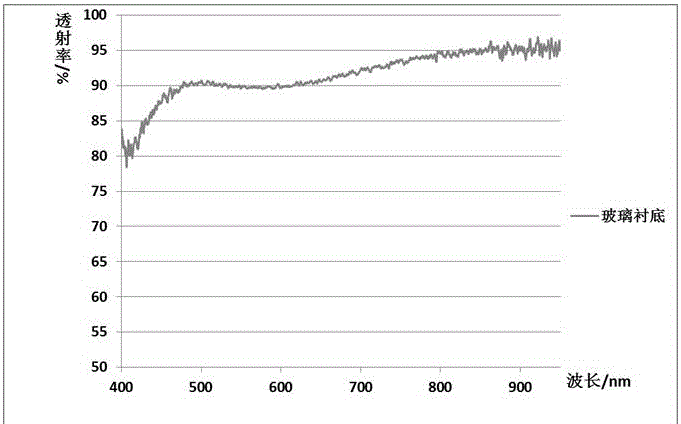

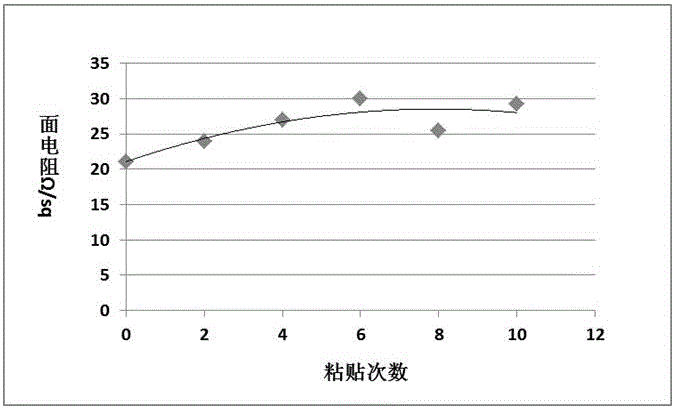

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com