Machine tool machining precision retaining ability prediction method based on rough set theory and least squares support vector machine

A technology of rough set theory and support vector machine, which is applied in the field of machine tool machining accuracy maintenance prediction, and can solve problems that are difficult to meet the requirements of real-time performance and prediction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

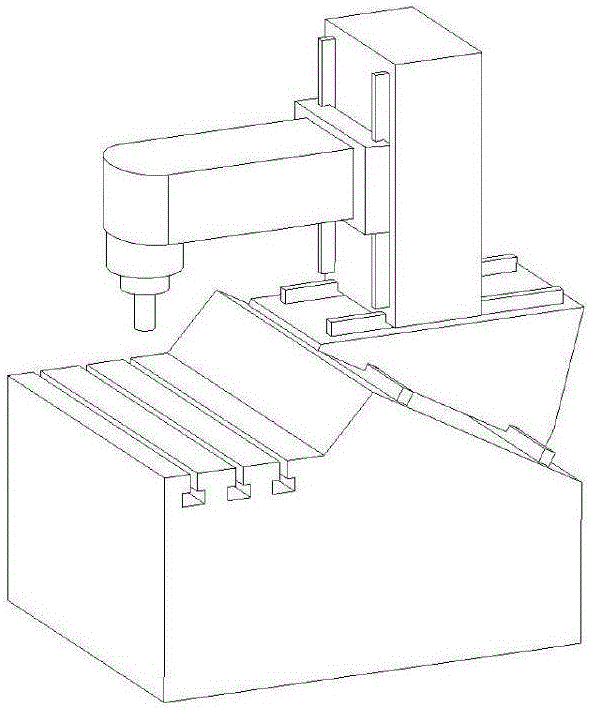

[0113] Calculation example: Take the three-axis linkage CNC machine tool as an example ( figure 1 )

[0114] Step 1: Establish the spatial comprehensive error model of the machine tool based on the screw theory

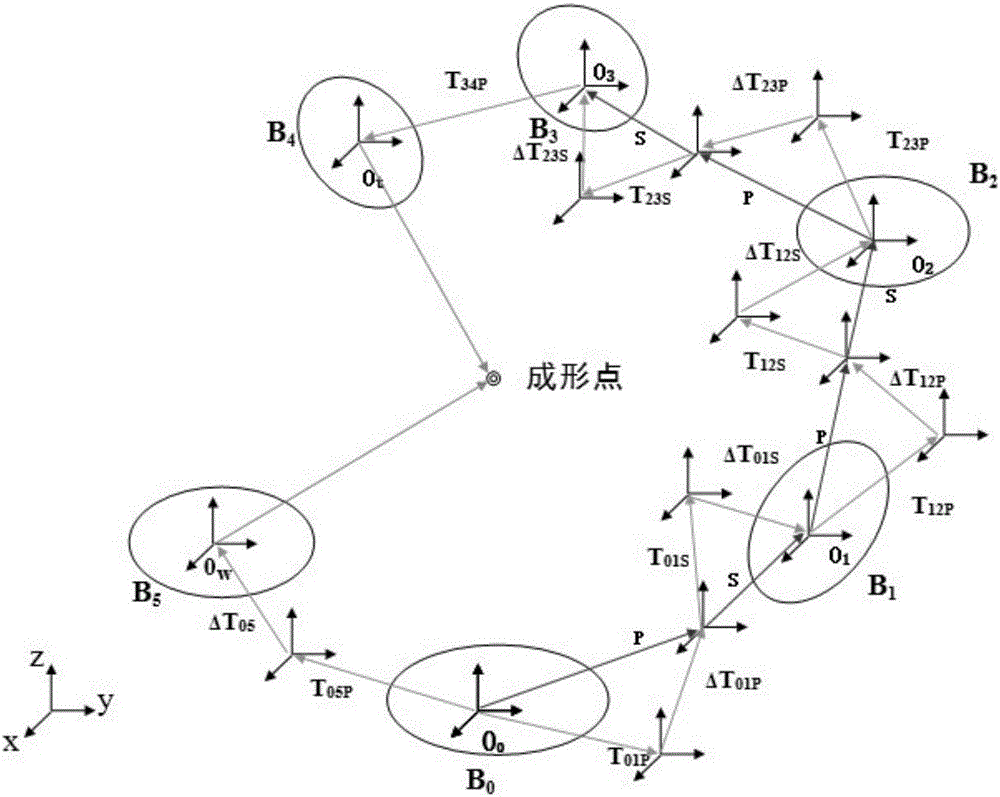

[0115] According to the exponential matrix form of the screw theory, each moving part of the machine tool is abstracted into a 6×1 vector form; the movement form and comprehensive error are modularized and expressed in the form of an exponential matrix, and the machine tool is established according to the topology of the machine tool The spatial comprehensive error model of ;

[0116] Step 1.1 Exponential matrix form of spinor theory

[0117] Application of screw theory to comprehensive error modeling of multi-axis machine tools. Due to its kinematic properties, the model can be used to describe the kinematic error of each axis and the overall error of the machine tool. The squareness error can also be described in detail by the screw model.

[0118] However, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com